External-cavity-beam-combination semiconductor laser fiber coupling module

A fiber coupling and semiconductor technology, applied in the field of single-tube semiconductor lasers, can solve the problems of poor beam quality and low output brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

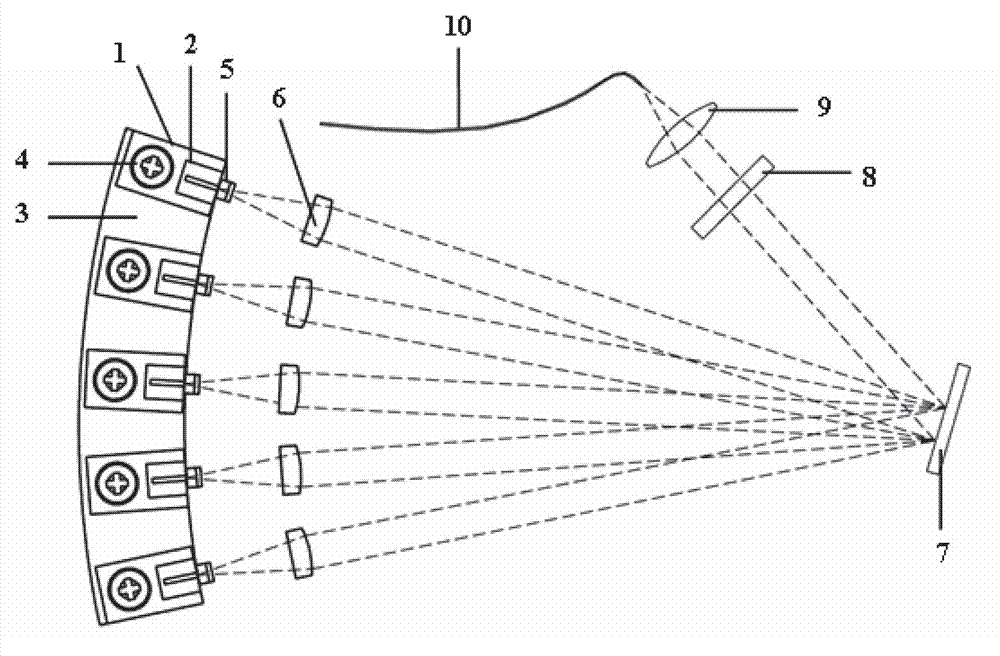

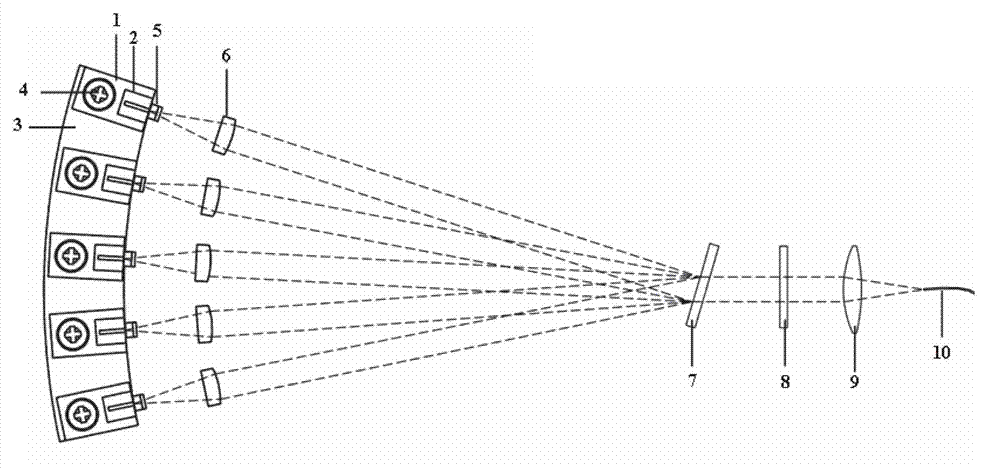

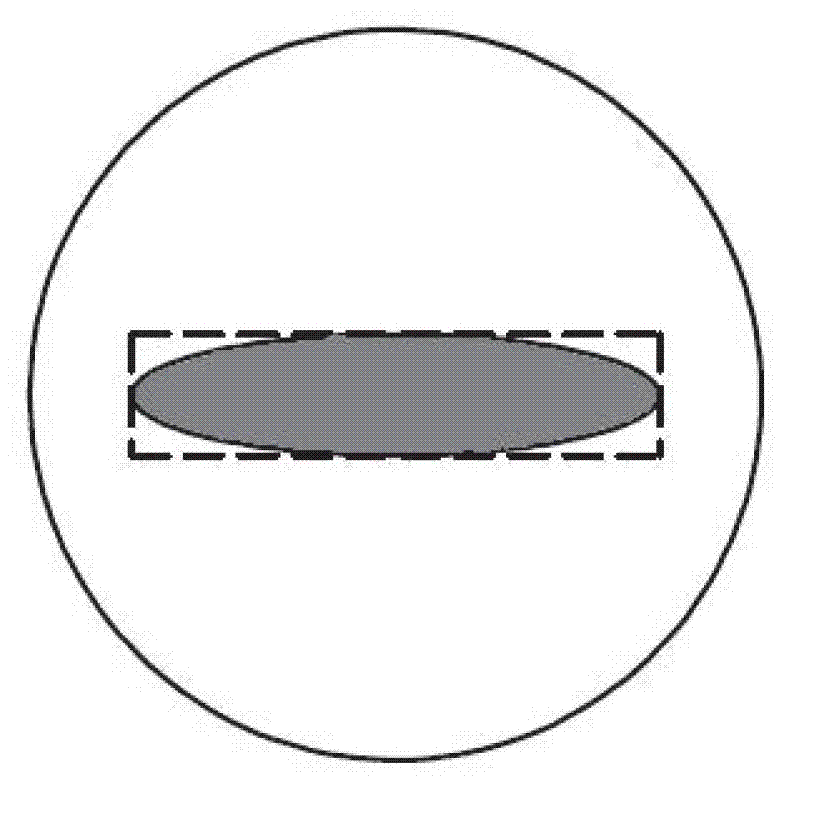

[0025] The inventive idea of the present invention is: a semiconductor laser single-tube beam-combining fiber coupling module, including a plurality of single-tube semiconductor lasers of the same wavelength; each of the single-tube semiconductor lasers is fixed on a transitional heat sink, and the transitional heat sink Fixed on the arc-shaped heat sink; multiple beams emitted by multiple single-tube semiconductor lasers are incident on the diffraction grating through different inclination angles, and the light spots overlap on the diffraction grating, and then diffract to the external cavity mirror at the same diffraction angle; multiple beams The beam is fed back by the external cavity mirror and returns along the original optical path, so that each single-tube semiconductor laser receives its own output feedback; multiple beams after the output feedback pass through the diffraction grating and then synthesize into one beam, which is coupled into the multimode fiber through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com