Optical fiber probe of fluorescent optical fiber temperature sensor and preparation method thereof

A temperature sensor, fiber optic probe technology, used in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of limited temperature measurement range, inability to measure temperature, poor measurement repeatability, etc., to increase service life and use. Reliability, preventing the influence of external interference light, and facilitating extraction and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the optical fiber probe of the fluorescent optical fiber temperature sensor comprises the following steps:

[0034] 1] Insert one end of the optical fiber into the connector and extend it, and fix it with glue;

[0035] 2] After fixing, cut off all the light-transmitting optical fibers protruding from the connector, and grind and polish the cut-off end face of the light-transmitting optical fibers;

[0036] 3] Coating reflective resin on the other end of the optical fiber that is not inserted into the connector to form a reflective resin layer, and coating phosphor powder on the surface of the reflective resin layer to form a fluorescent layer;

[0037] 4] Put the light-transmitting optical fiber not inserted into the connector into the protective sleeve, the sleeve is passed to the connector, and epoxy resin is applied between the connector and the connector to fix it. The end face of the protective sleeve near the fluorescent layer is The ve...

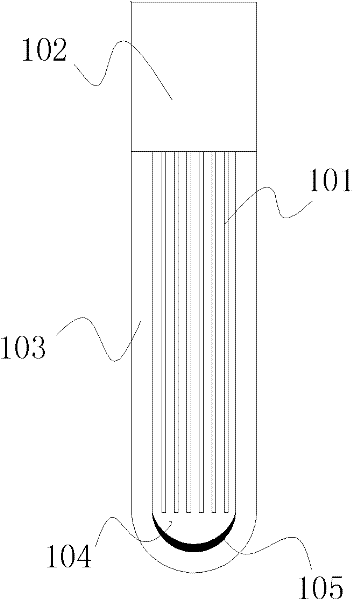

Embodiment 1

[0041] In this embodiment, a bundle of multi-component glass optical fibers 101 is used. One bundle contains approximately 10 to 1000 single glass optical fibers, the core diameter of a single glass optical fiber is 20 to 50 μm, the numerical aperture is 0.3 to 0.8, and the length is 0 to 100 m. 101 is covered with a polytetrafluoroethylene tube 103, one end of the optical fiber bundle 101 is added with a connector 102, fixed with glue, ground and polished, the other end of the optical fiber bundle 101 is coated with silicone resin 104, and the surface of the silicone resin 104 is coated with fluorescent powder 105. Cut off the casing at one end of the fluorescent powder 105 at a point 5-10 mm longer. Use a sealing machine to seal the sleeve tube at one end of the fluorescent powder 105. The advantage of this embodiment is that a bundle of multi-core glass optical fibers is used, which is resistant to high temperature and bending, and the demodulated signal is not affected by ...

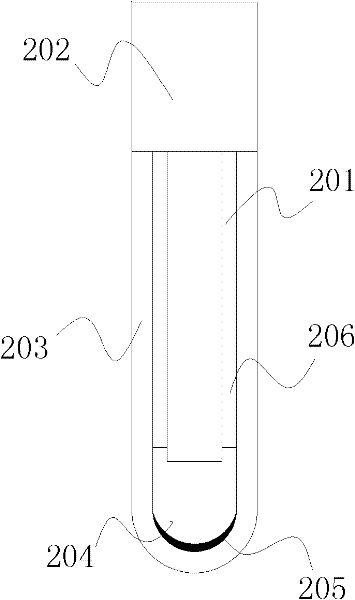

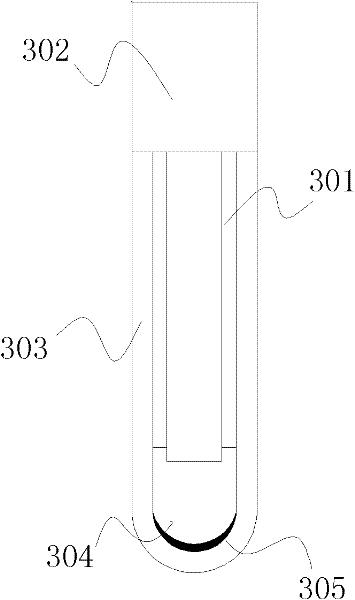

Embodiment 2

[0043]In this embodiment, a quartz optical fiber 201 is used. The core diameter of the quartz optical fiber 201 is 200-400 μm, the numerical aperture is 0.1-0.3, and the length is 0-100 m. The outer diameter of the quartz optical fiber 201 is coated with acrylic resin 206. Add a connector 202 at one end, fix it with glue, grind and polish it, peel off the coating layer about 5mm at the other end, grind and polish the end face of the optical fiber, glue silicone resin 204 on the end face of the optical fiber, and coat the surface of the silicone resin 204 with fluorescent light Powder 205. Dot 353ND glue or other epoxy resin around the optical fiber with the coating stripped off, insert a black glass tube 203 with an inner diameter of 0.6-1.0 mm and an outer diameter of 0.8-1.5 mm, and seal one end of the black glass tube 203 . The advantage of this embodiment is that a quartz optical fiber is used, which is easy to process and can withstand high temperature, and the fluorescen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com