Multi-single pipe light beam coupling type high-power semiconductor laser

A semiconductor and laser technology, applied in the field of high-power semiconductor lasers, can solve the problems of large current and voltage, complex adjustment, high cost, etc., achieve high power and brightness output, overcome the effect of complex structure and easy components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

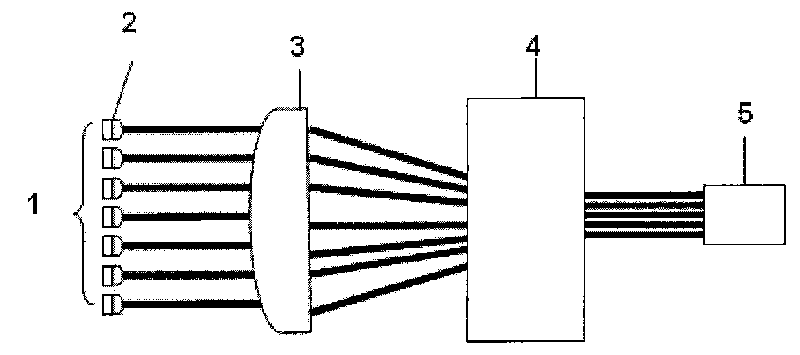

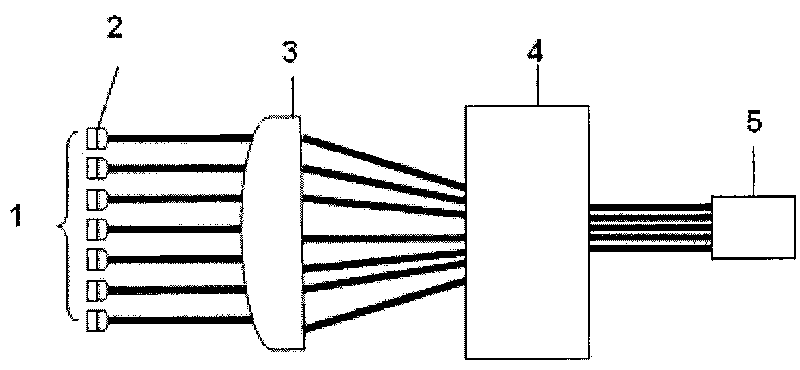

[0012] refer to figure 1 , a multi-single-tube beam-coupled high-power semiconductor laser, is that 7 single-tube semiconductor lasers 1 with fast-axis collimating cylindrical lenses 2 are arranged in parallel in the same direction, along the number of single-tube semiconductor lasers. The optical path transmission direction of the laser 1 is successively provided with a cylindrical lens 3, a slow-axis collimating mirror 4 perpendicular to the normal line of the cylindrical lens 3, and an optical fiber 5 receiving its focused light beam; The fast axis of the beam of 1 is further compressed, and the slow axis collimator 4 collimates the slow axis and focuses the beam, and finally the beam is focused and coupled into the optical fiber 5 for output.

[0013] The cylindrical lens 3 is a spherical cylindrical lens.

[0014] The cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com