Vehicle failure intelligent setting, practical training and check-out system and realization method thereof

A technology of automobile faults and realization methods, which is applied in space navigation equipment, simulation devices of space navigation conditions, instruments, etc., can solve the problems of high difficulty in problem solving, heavy workload, and time-consuming problem of problem solving, achieving a large fault coverage, High work efficiency and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

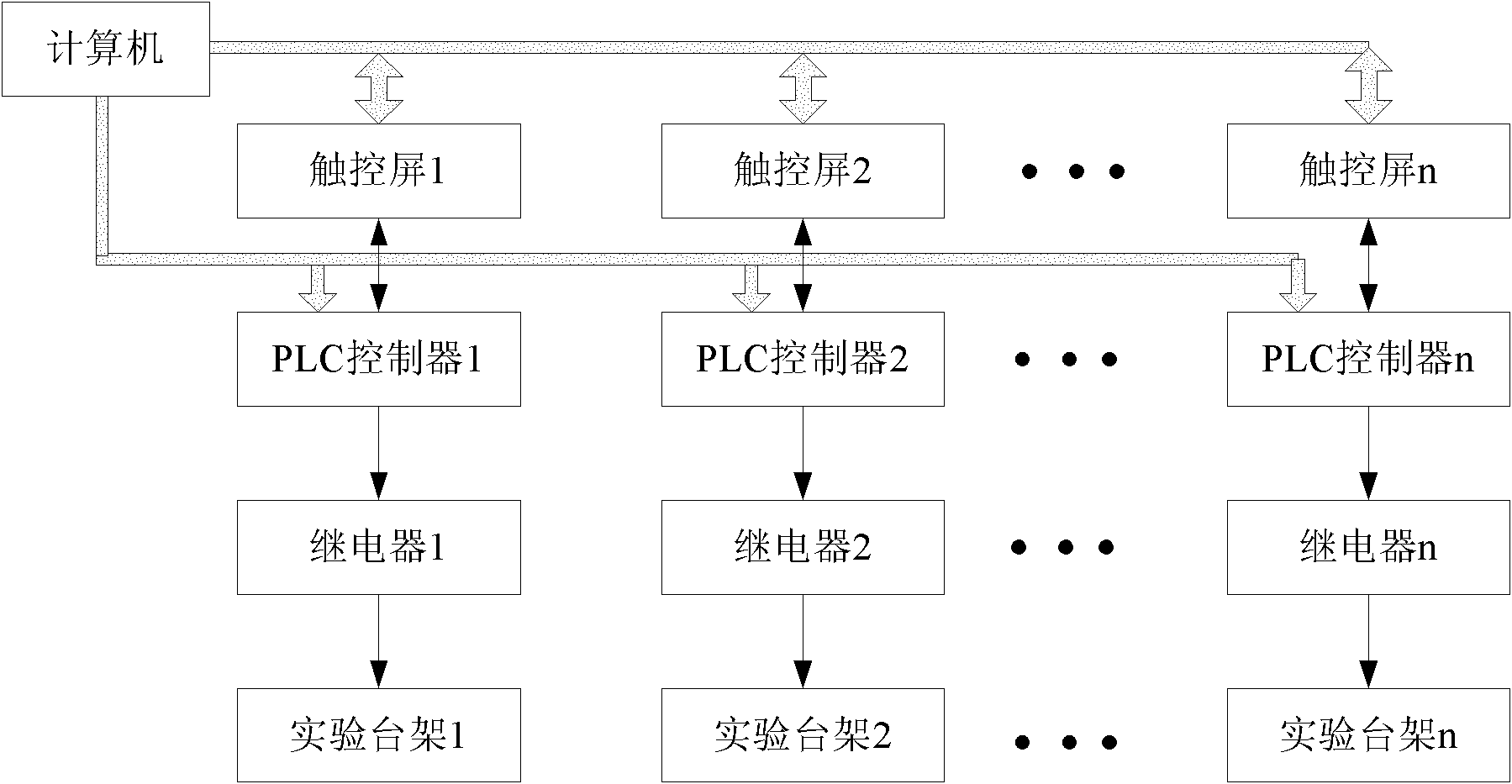

[0040] like figure 1 As shown, the online version of the vehicle failure intelligent setting, training and assessment system includes a test stand, a relay, a PLC, and a touch screen. The test stand is connected to the PLC through a relay, and the PLC communicates with the corresponding touch screen connected to the control screen. Wherein, the computer refers to the teacher's computer operated by the teacher, and the touch screen refers to the touch-screen computer operated by the student.

[0041]In order to realize the network function, there are multiple PLCs, and each PLC is correspondingly connected with a touch screen, and is connected with a corresponding test bench through a relay; all PLCs are connected with the same test bank It is connected with a computer in the database, and the computer is connected with the multiple touch screens through a network.

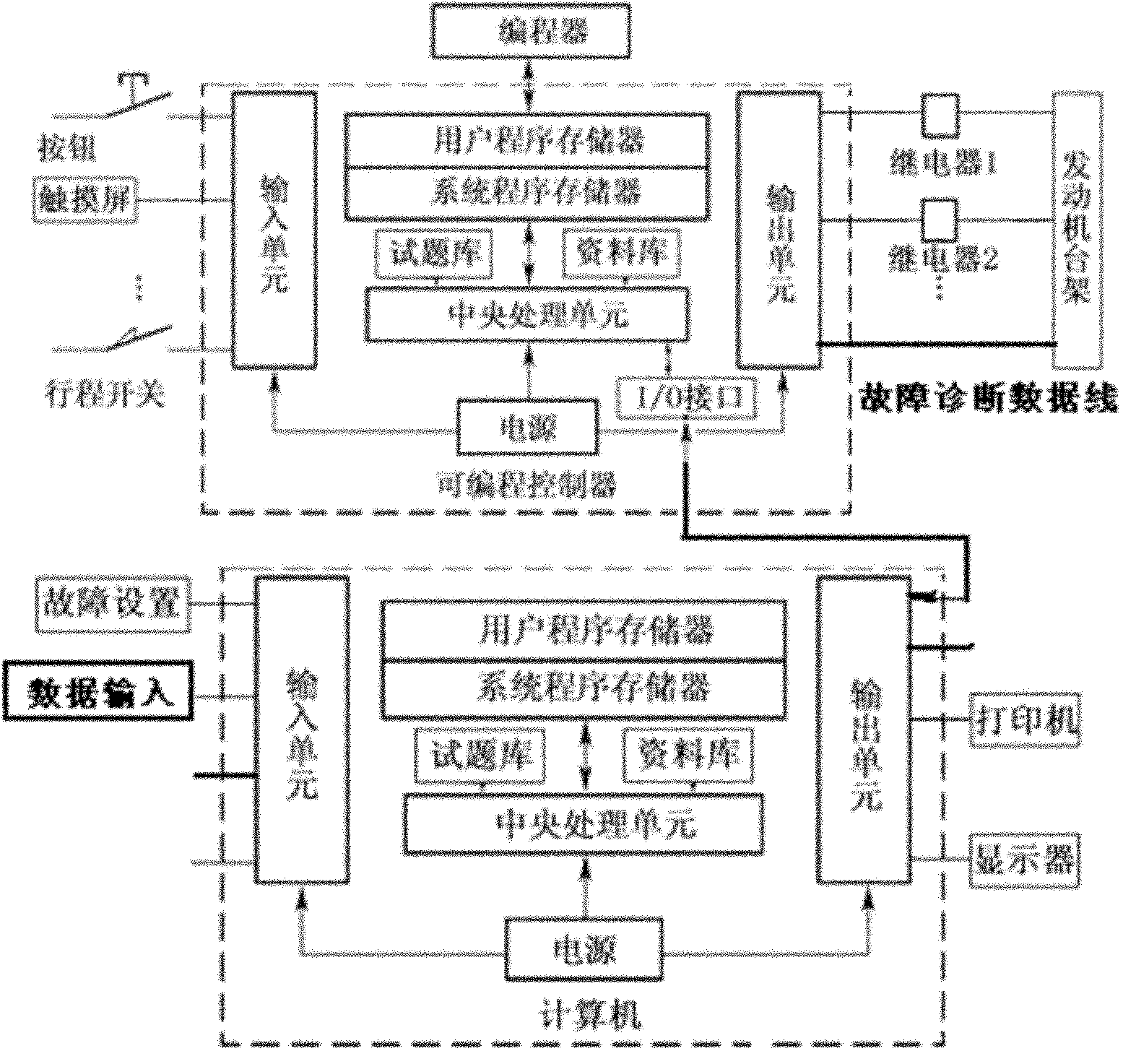

[0042] The computer is provided with a central processing unit, a test question bank, a database, a storage un...

Embodiment 2

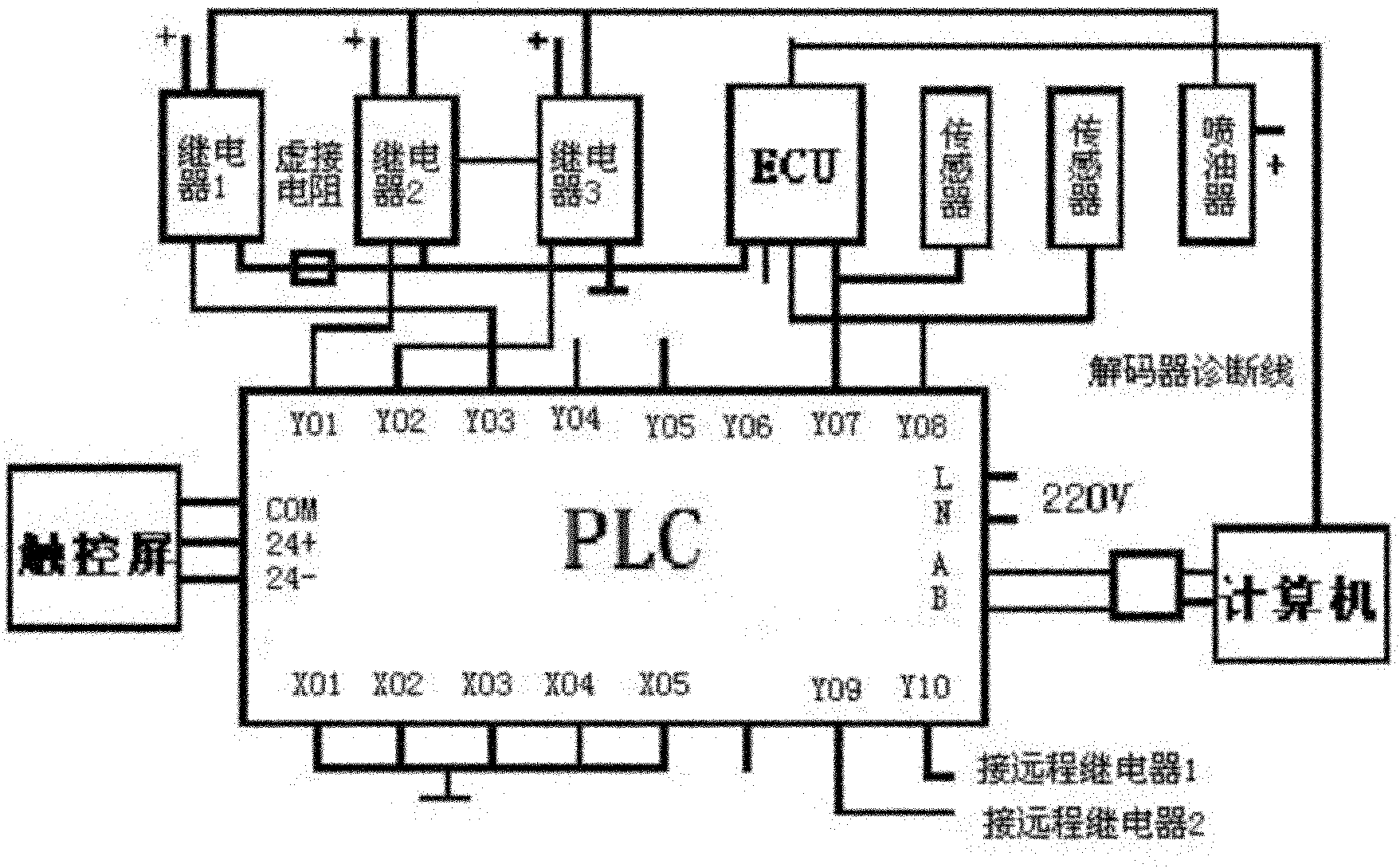

[0067] Present embodiment except following feature other structures are with embodiment 1: as Figure 5 As shown, the stand-alone version of the automobile failure intelligent setting, training, and assessment system includes a test bench, a relay, a PLC, and a touch screen. The test bench is connected to the PLC through a relay, and the PLC is directly connected to the touch screen. connected. Among them, the touch screen is both the teacher's machine and the student's machine, and the touch screen can also be replaced by a computer.

[0068] The PLC is provided with a central processing unit, a test question bank, a database, a storage unit, an input unit and an output unit, and the central processing unit is connected with the test question bank, a database, a storage unit, an input unit and an output unit respectively; The storage unit contains a scoring unit, which is used for scoring and counting the students' answering results.

[0069] The following also takes the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com