Metal 3d printer

一种三维打印机、金属的技术,应用在金属加工设备、制造工具、加工环境调节等方向,能够解决制品品质下降、金属微粒子掉落、混入等问题,达到金属粒子减少、品质与安全性提高、生产效率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

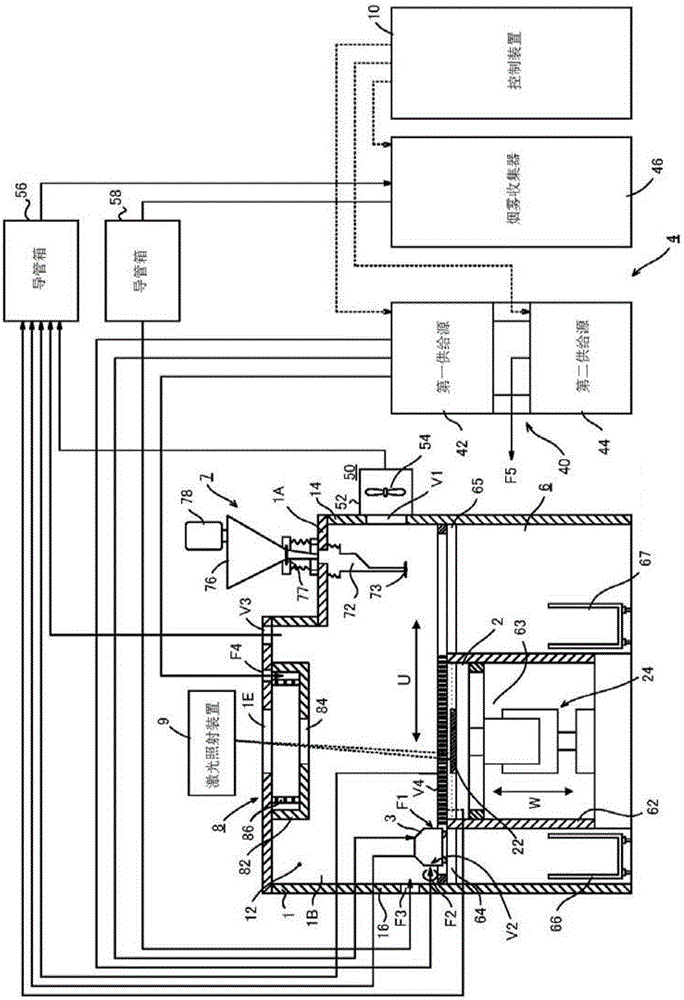

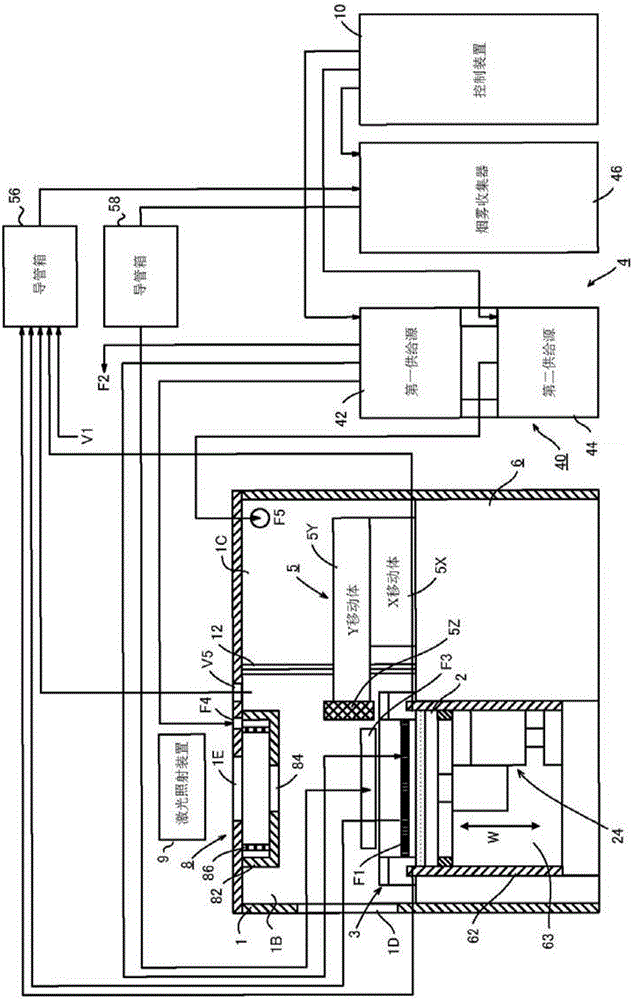

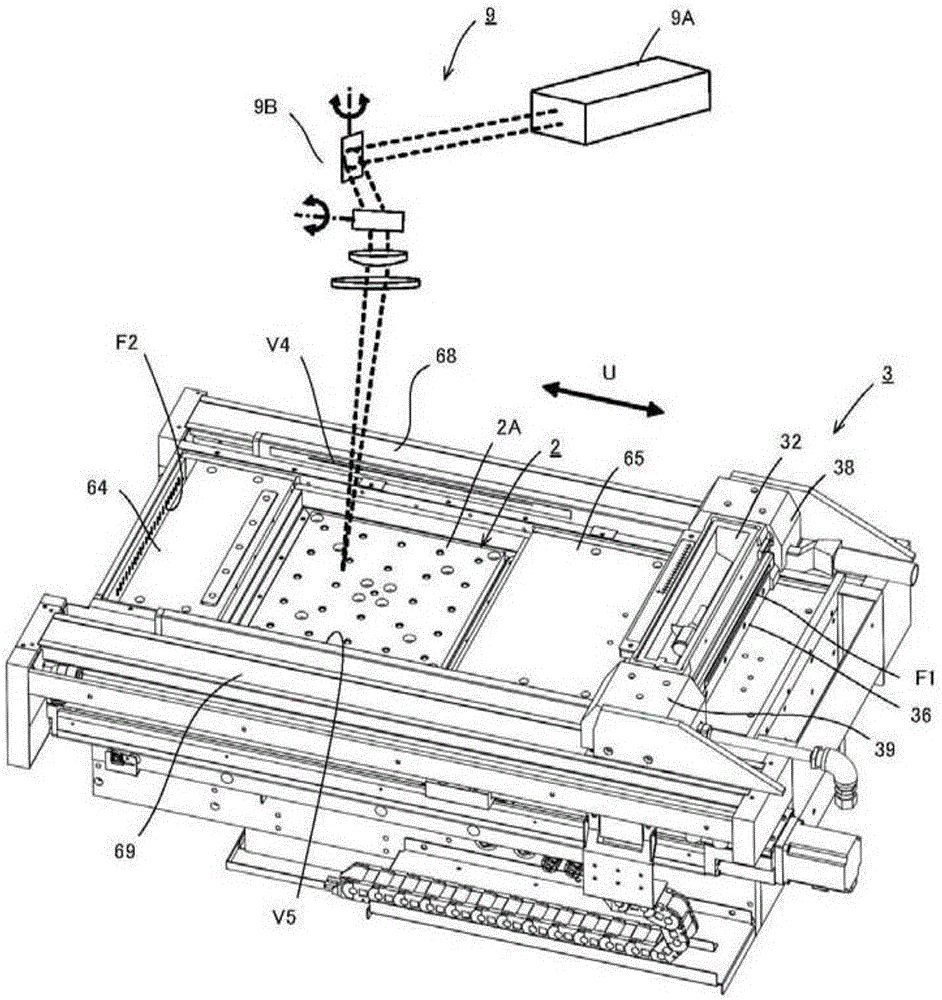

[0095] One embodiment of the present invention will be described in detail with reference to the drawings. figure 1 and figure 2 The dotted line in represents the signal line, image 3 The dotted line in indicates the irradiation path of the laser beam.

[0096] A metal 3D printer that repeatedly sinters metal powder to create a three-dimensional object is illustrated in figure 1 and figure 2 middle. The metal three-dimensional printer includes a housing 1 , a recoater head 3 , a material supply device 7 , an inert gas supply device 4 , a power supply device, a control device 10 and a fume collector 46 . The power supply unit, the control unit 10 and the smoke collector 46 are located at the rear of the casing 1 .

[0097] The casing 1 is a part that forms an environment in which the oxygen concentration is lower than a predetermined value. The casing 1 includes a top plate and four side walls, forming a closed chamber. The airtight chamber is partitioned by bellows 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com