Automatic soldering tin machine for terminal pin of transformer

A technology of lead pins and transformers, applied in welding equipment, auxiliary devices, printed circuits, etc., can solve the problems of accumulating impurities, affecting normal operations, and high labor costs, and achieves the advantages of convenient cleaning or replacement, improved work efficiency, and quality assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

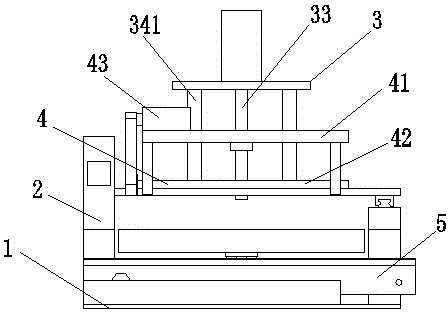

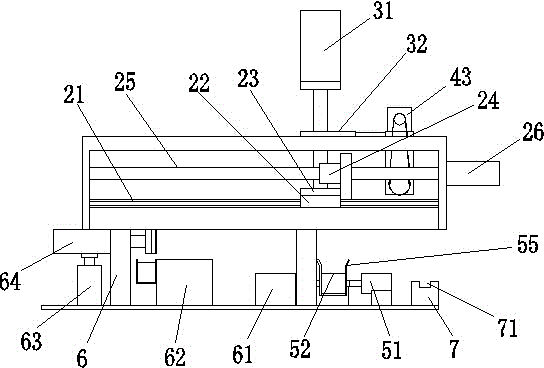

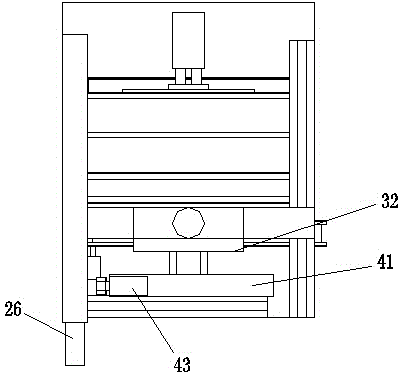

[0038]It includes a frame, a traverse device, a lifting device, a clamping device, a soldering device and a conveying device. The traverse device includes a guide rail, a slider, a traverse plate, a sliding sleeve, a traverse screw and a traverse motor. The guide rail is fixed on the frame, the slider fits on the guide rail and can move linearly along the guide rail, the traversing plate is fixed on the slider, and the sliding sleeve is sleeved on the traversing screw rod and fixed with the traversing plate , the traversing motor is connected with the traversing screw; the lifting device includes a lifting motor, a lifting plate, a lifting screw and a lifting frame with a guide rod, and the lifting frame is fixed on the traversing plate and is controlled by the traversing plate Drive the lifting device to move horizontally as a whole, the lifting motor is fixed on the lifting frame and connected with the lifting screw, the lifting plate passes through the guide rod and cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com