Block-free balanced-pressure clog-proof device for sewage and surface water source heat pump and system therefor

A surface water source heat pump, non-blocking technology, applied in heat pumps, artificial waterways, water conservancy projects, etc., can solve problems such as maintenance difficulties, short cleaning cycles of heat exchange equipment filter devices, and inability to meet system water supply requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

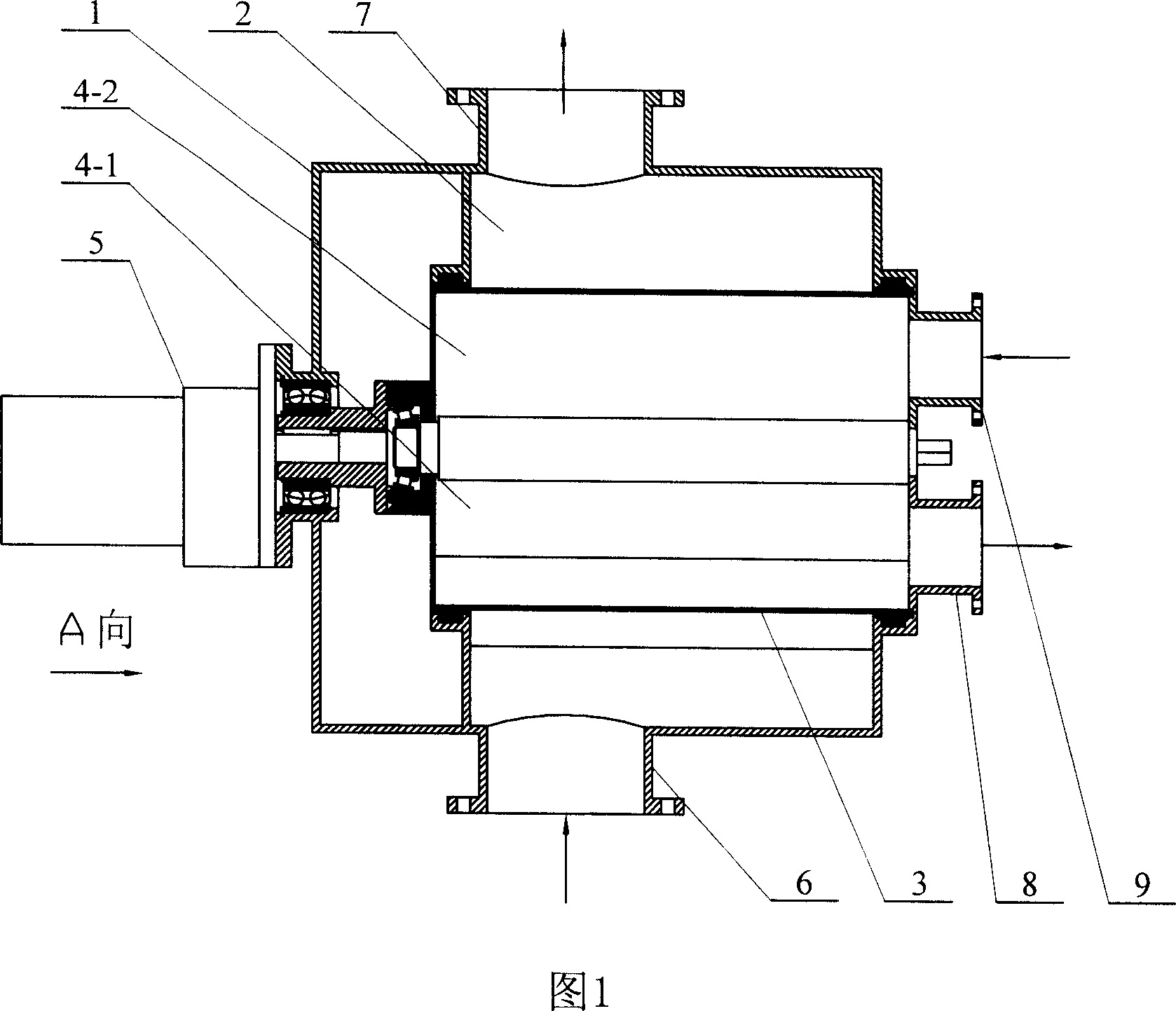

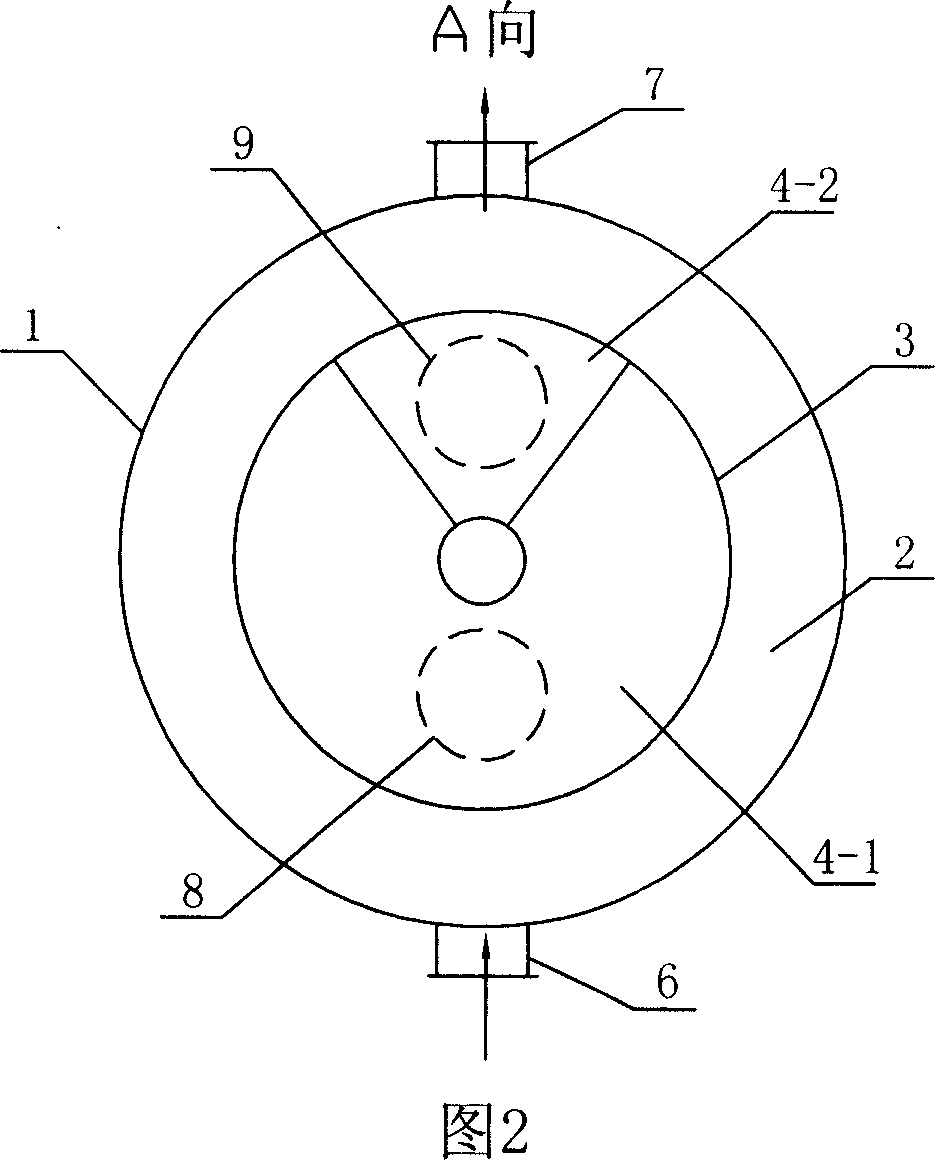

[0018]Specific embodiment 1: As shown in Figure 1 and Figure 2, the filter surface non-blocking and anti-blocking device of this embodiment consists of an outer shell 1, a rotating filter cartridge 3, a water inlet area 4-1 in the cylinder, and a water outlet area 4- in the cylinder. 2. The transmission device that drives the rotary filter cartridge 3 to rotate 5, the water inlet 6 outside the cartridge, the drain outlet 7 outside the cartridge, the outlet 8 of the water inlet area inside the cartridge, and the inlet 9 of the water outlet area inside the cartridge. The water inlet 6 and the drain outlet 7 outside the cylinder, the rotary filter cartridge 3 is arranged inside the outer casing 1, and the inside of the rotary filter cartridge 3 is divided into the water inlet area 4-1 in the cylinder and the water outlet area 4-2 in the cylinder, the water inlet area in the cylinder The water area 4-1 communicates with the outlet 8 of the water inlet area in the cylinder, and the ...

specific Embodiment approach 2

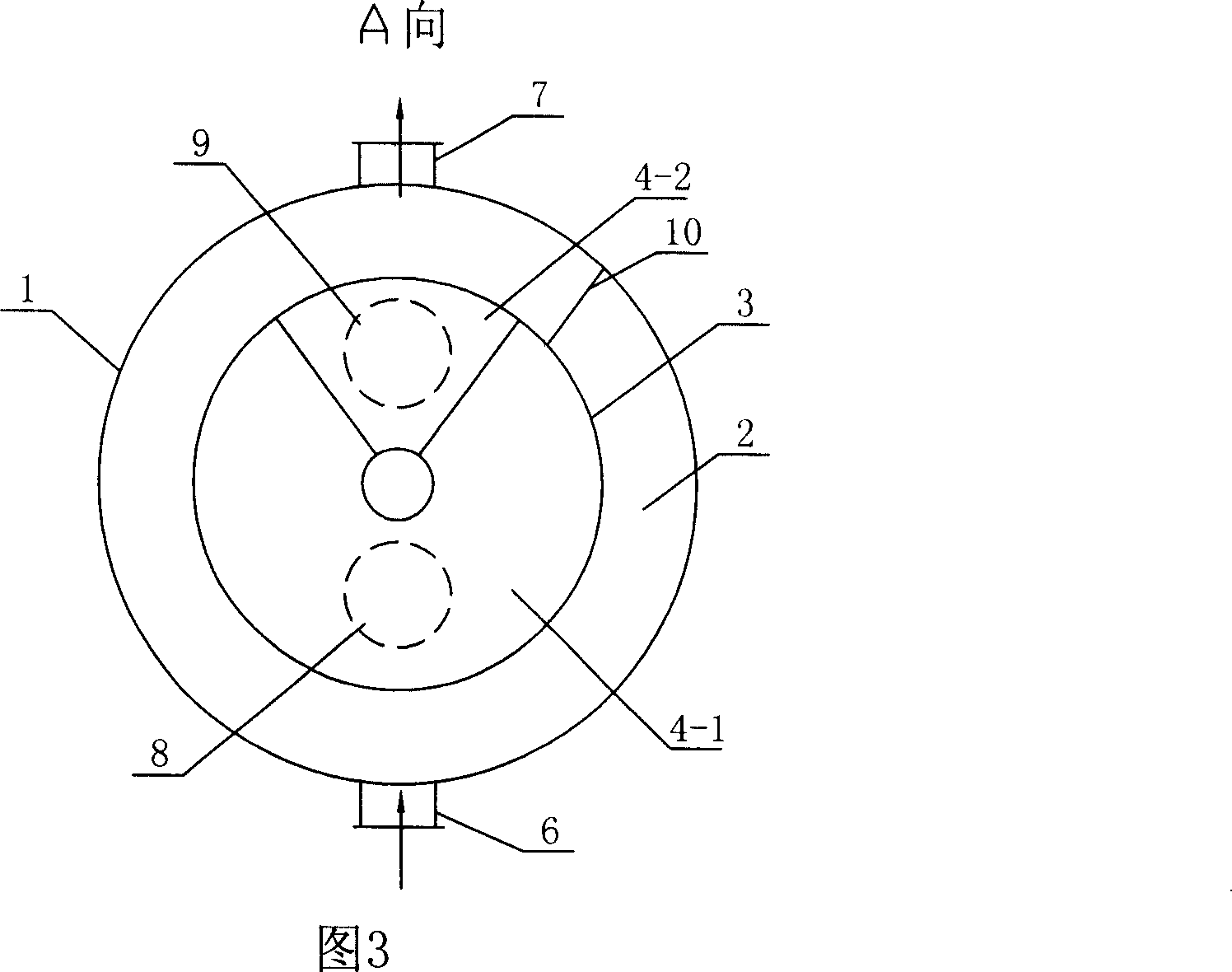

[0019] Specific embodiment two: as shown in Figure 3, according to actual needs, a hairbrush 10 can also be added in the anti-blocking device. The surfaces of the barrel 3 are in contact. When the anti-blocking device is in operation, the hair brush 10 is stationary, and the rotating filter surface is cleaned under the rotation of the rotating filter cartridge 3 . The increase of hairbrush 10 is to clean the dirt that hangs on the wall and cannot be backwashed on the filter surface, and plays an auxiliary cleaning effect when the backwash effect is not good, so as to ensure the cleaning effect of the filter surface.

[0020] Working principle: When the anti-blocking device is working, the transmission device 5 such as the motor and reducer drives the rotatable filter cartridge 3 to rotate, and the filter surface is continuously exchanged between the water inlet area 4-1 and the water outlet area 4-2 in the cylinder, and the rotation The speed is adjustable. The sewage enters...

specific Embodiment approach 3

[0021] Specific embodiment three: As shown in Figure 4, the secondary pump system of this embodiment is composed of primary pump 11, sewage and surface water source heat pump non-blocking pressure balance anti-blocking device 13, secondary pump 14, heat exchanger 15, connection The pipeline 12 and the drainage pipeline 16 are composed. The primary pump 11 communicates with the water inlet 6 outside the cylinder of the anti-blocking device 13 through the connecting pipeline 12, and the inlet of the secondary pump 14 is connected with the cylinder of the anti-blocking device 13 through the connecting pipeline 12. The outlet 8 of the inner water inlet area is connected, the outlet of the secondary pump 14 is connected with the inlet of the heat exchanger 15 through the connecting pipeline 12, and the outlet of the heat exchanger 15 is connected with the inlet of the inner water outlet area of the anti-blocking device 13 through the connecting pipeline 12 9 communicates, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com