Manufacturing method of USB connector with double-face inserting function

A manufacturing method and connector technology, applied in connection, contact manufacturing, contact assembly/disassembly, etc., can solve problems such as interface damage, inconvenient use, USB connector damage, etc., to prevent short-circuit phenomenon and reduce defectiveness Product, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

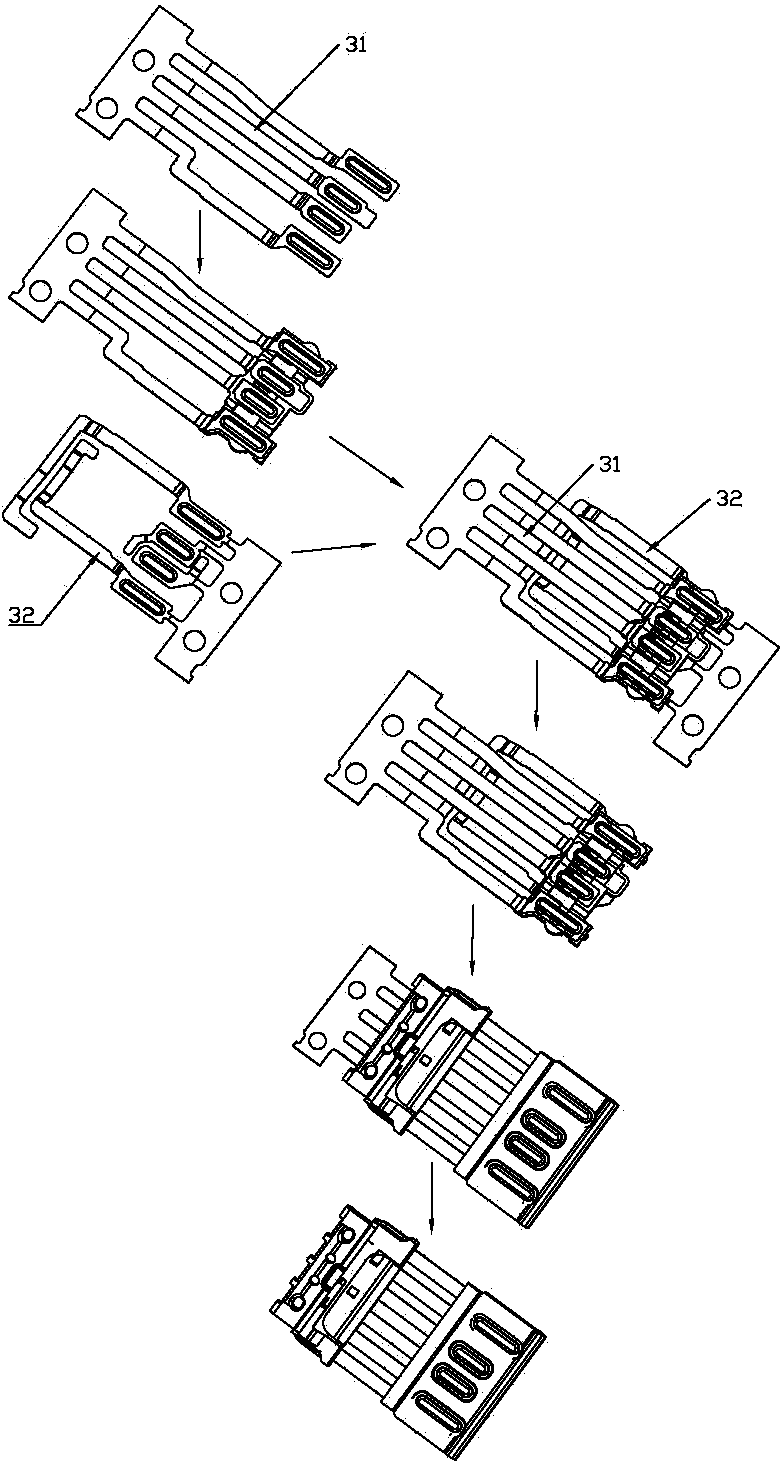

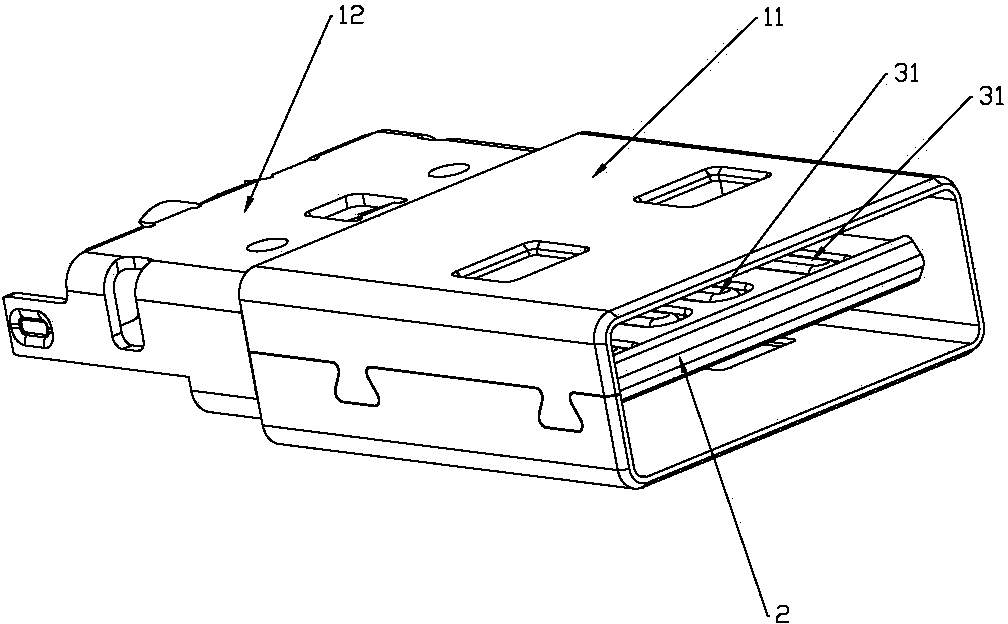

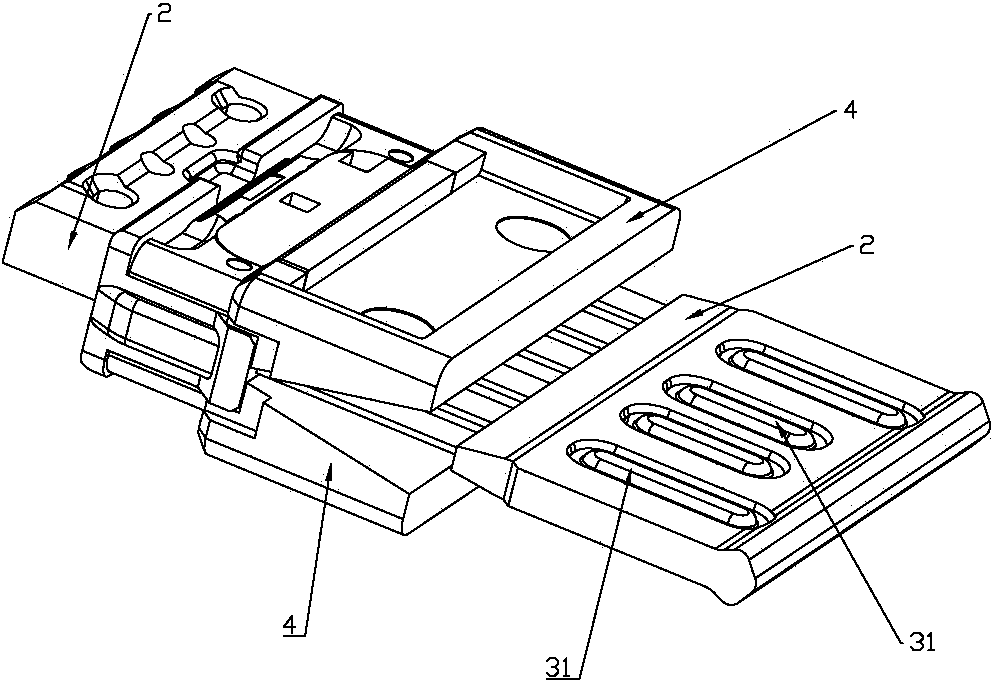

[0025] Such as figure 1 As shown, a method for making a double-sided USB connector includes the following steps:

[0026] Step 1: Perform the first injection molding on the upper terminal 31 ; the main purpose of this step is to fix the four contacts of the plug-in end of the upper terminal 31 .

[0027] Step 2: Lasering the lower terminal 32 and the upper terminal 31 of the first injection molding together; installing the lower terminal 32 under the upper terminal 31, due to the first injection molding, the upper terminal 31 will not appear in this laser operation In the case of a contact short circuit with the contact of the lower terminal 32, the connection in this step is beneficial to the secondary injection molding of the conductive terminal.

[0028] Step 3: Carry out the second injection molding of the lasered conductive terminal. After secondary injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com