Bipolar all-solid-state battery

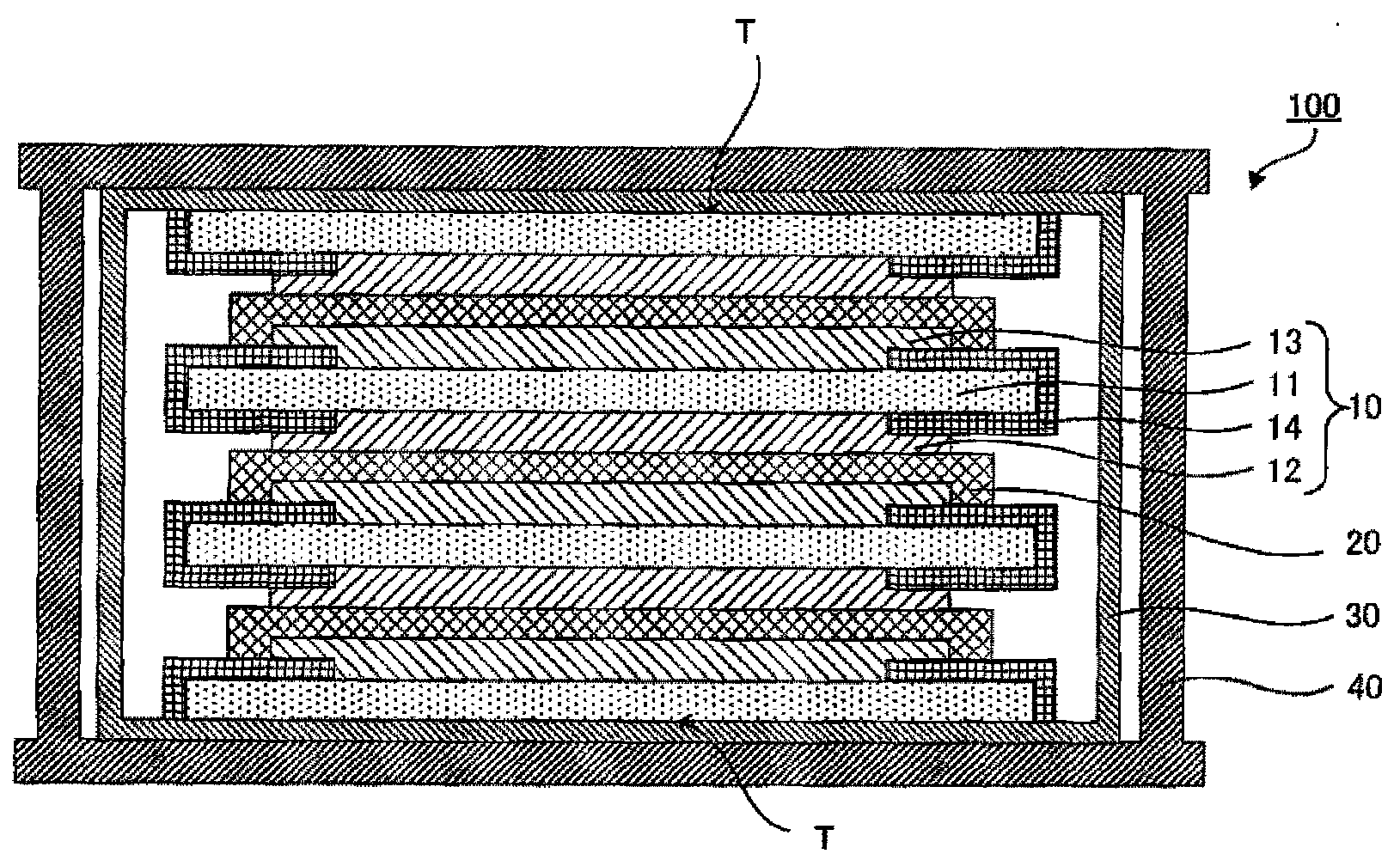

An all-solid battery and bipolar electrode technology, which is applied to batteries with bipolar electrodes, electrode carriers/collectors, lithium batteries, etc., can solve problems such as short circuits, and achieve the effect of preventing damage and preventing short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] Examples are shown below to further describe the present invention in detail.

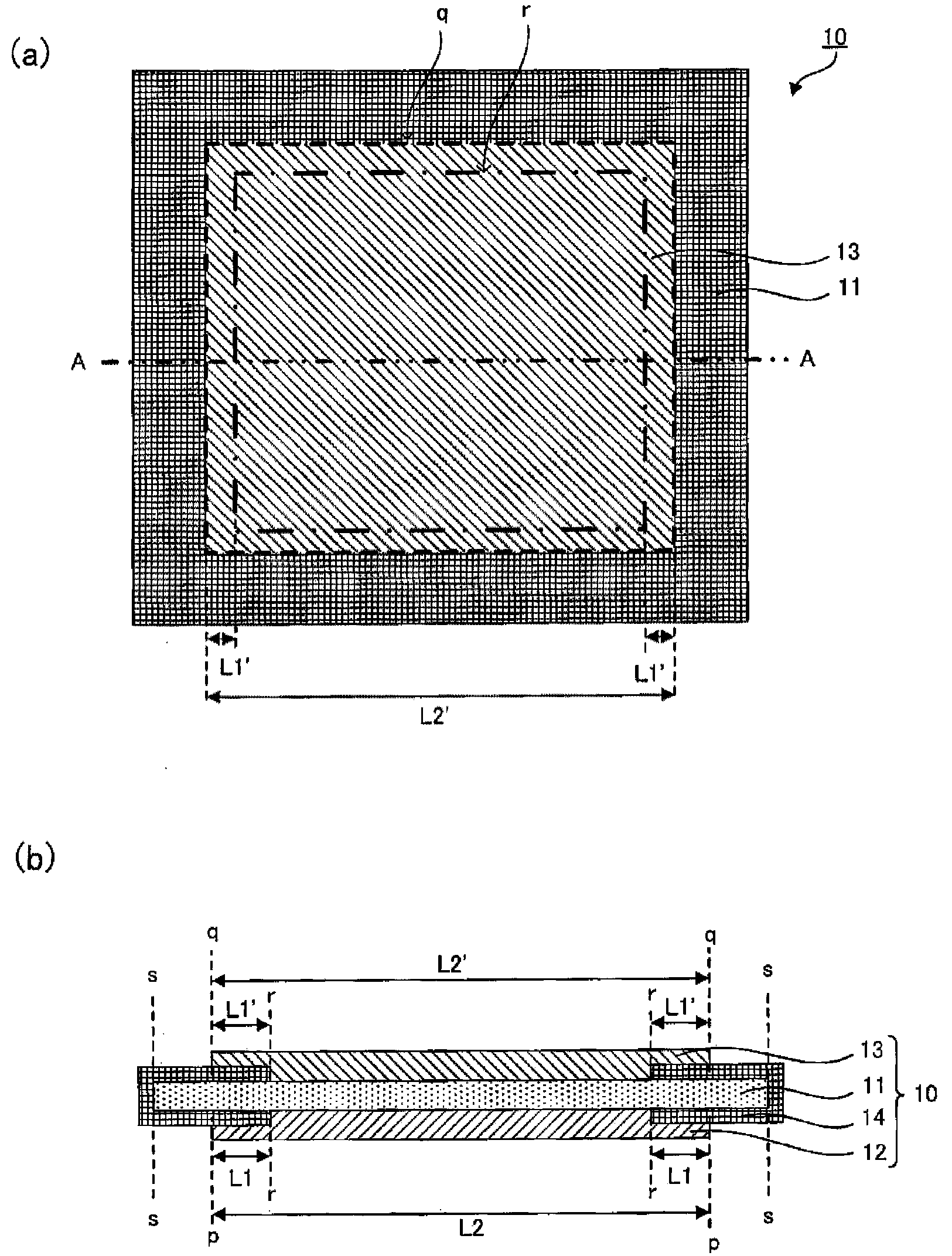

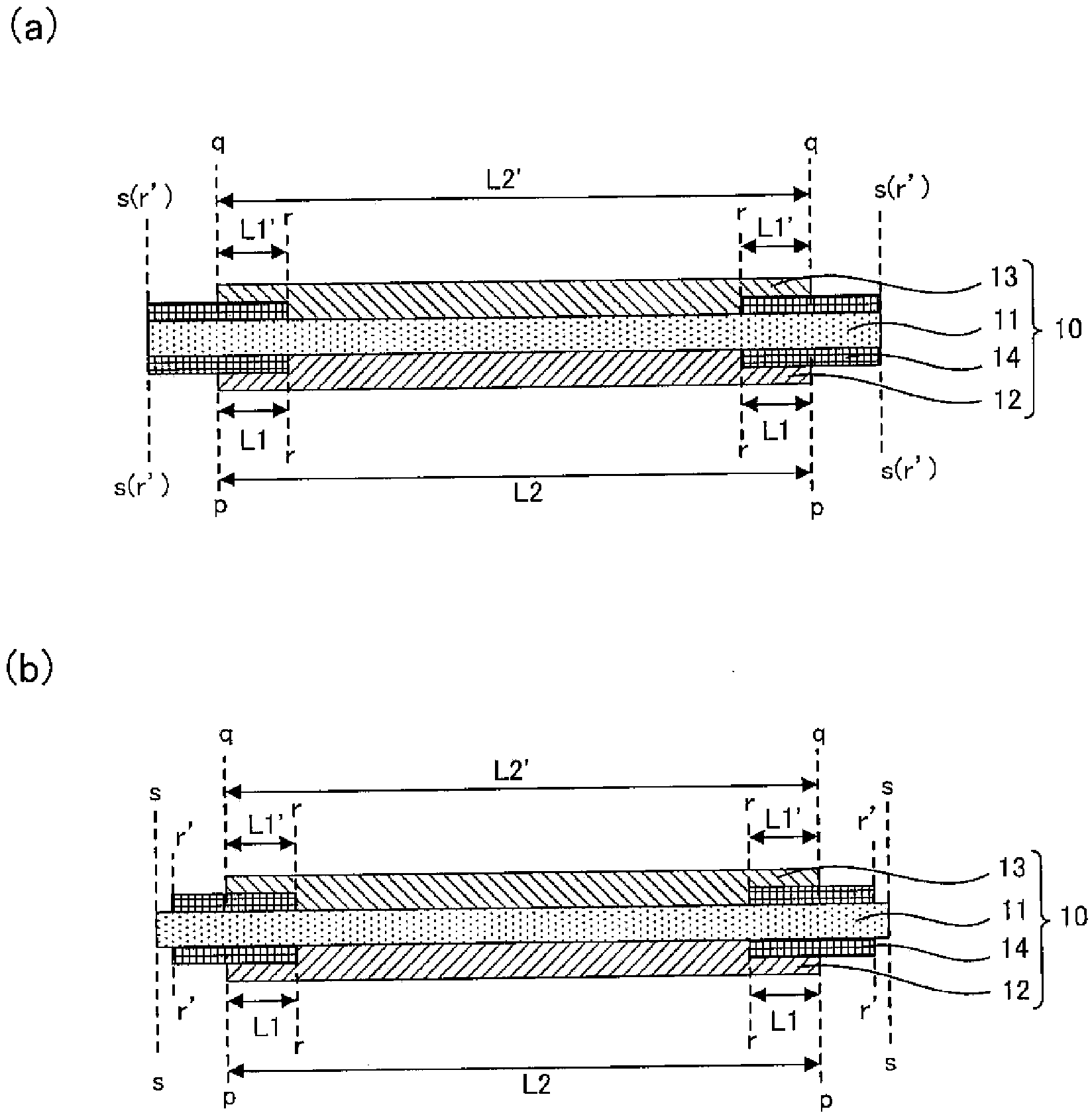

[0106] A SUS304 foil with a thickness of 10 μm was prepared as a current collector, and a PEN film with a thickness of 12 μm was bonded to the outer periphery of the SUS304 foil by thermocompression as a reinforcing layer. It should be noted that the reinforcing layer was bonded to both surfaces of the current collector by thermocompression.

[0107] Next, the LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 (positive active material), 75Li 2 S-25P 2 S 5 (solid electrolyte), butene rubber (manufactured by JSR Corporation) (bonding material), and heptane (solvent) were mixed at a mass ratio of positive electrode active material:solid electrolyte:binding material:heptane=47:16:1:36 , kneaded to form a slurry, and the reinforcement layer was formed on the inner side of the end of the positive electrode active material layer, coated on the current collector and dried to obtain a positive electrode with a thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com