Separator, manufacturing method thereof, and electrochemical device employing same

一种隔膜、导电材料的技术,应用在隔膜、其制造和使用该隔膜的电化学器件领域,能够解决电极短路等问题,达到防止短路、优异输出特性、抑制短路的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

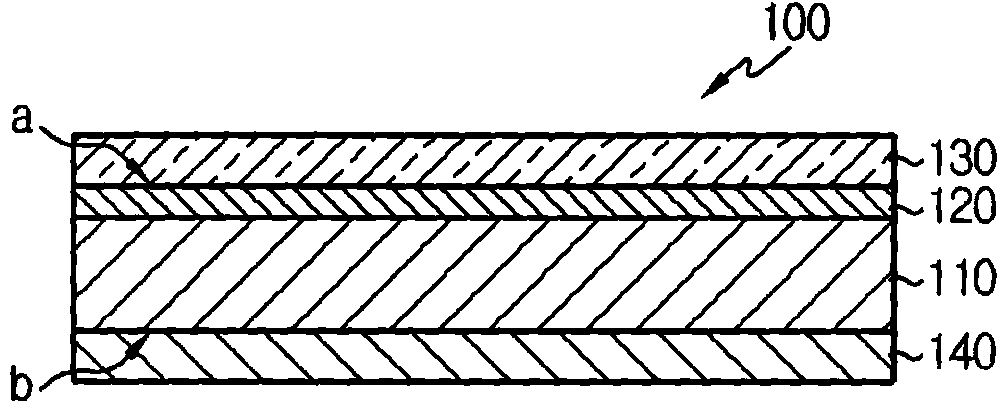

[0113] Example 1: Fabrication of an Inorganic-Organic Coating / Active Material Coating Containing Conductive Material diaphragm

[0114] Polyvinylidene fluoride-chlorinated trifluoroethylene copolymer (PVdF-CTFE) and cyanoethylpullulan (cyanoethylpullulan) were added to acetone at a weight ratio of 10:2 and dissolved at 50 °C for about 12 hours to obtain a polymer solution. Will Al 2 o 3 The powder was added to the polymer solution until the polymer / inorganic particle weight ratio reached 5 / 95, and then the inorganic particles were pulverized and dispersed using a ball mill method for 12 hours to prepare a first slurry.

[0115] Also, to the same polymer solution as above was added LiFePO including a conductive material in an amount of 2%. 4 The powder was powdered until the weight ratio of polymer / inorganic particles reached 10 / 90, and then the inorganic particles were pulverized and dispersed using a ball milling method for 12 hours to prepare a second slurry.

[0116...

Embodiment 2

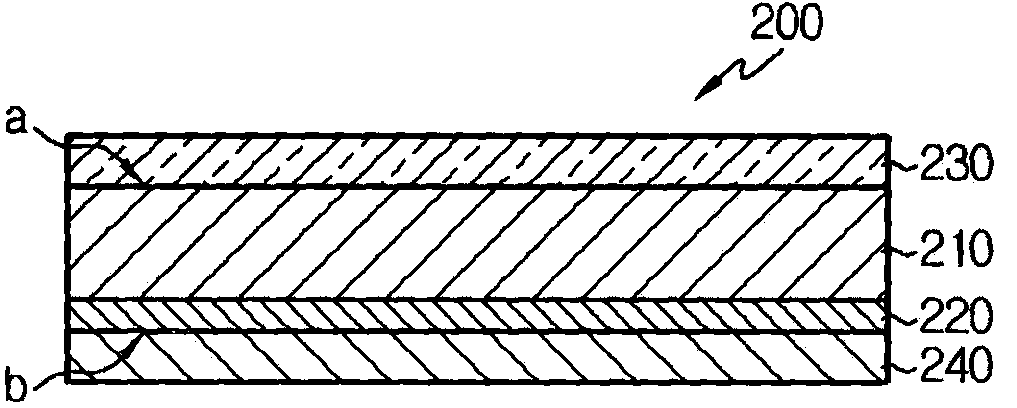

[0119] Example 2: Fabrication of Active Material Coatings with Inorganic-Organic Coatings / Containing Conductive Materials / Separator with adhesive polymer layer

[0120] The diaphragm was prepared in the same steps as in Example 1, and then the polyvinylidene fluoride-chlorinated trifluoroethylene copolymer (PVdF-CTFE) solution was coated on both surfaces of the diaphragm with a thickness of 3 μm by electrospray method to obtain Separator with electrode-separator adhesive layer.

Embodiment 3

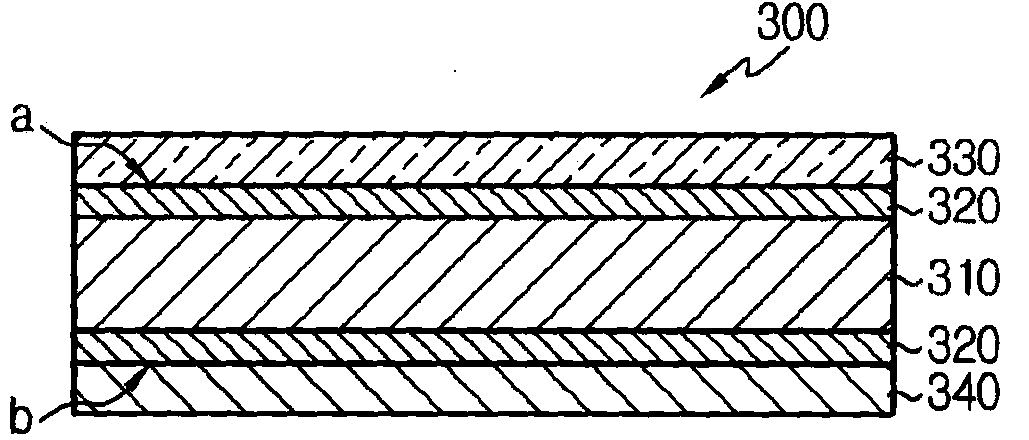

[0121] Example 3: Fabrication of Active Material Coatings with Inorganic-Organic Coatings / Containing Conductive Materials / Separator with adhesive polymer layer

[0122] The procedure of Example 1 was repeated except that the third slurry was not applied to prepare a separator, and then the same electrospray method as in Example 2 was performed to obtain a separator having an electrode-separator adhesive layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com