Wastewater treatment device of horizontal polar plate multi-electrodes electrocatalysis reactor

A multi-dimensional electrode and wastewater treatment technology, which is applied in the direction of electrochemical water/sewage treatment, etc., can solve the problems of aeration effect, current efficiency unit space-time efficiency and treatment efficiency, unsatisfactory wastewater treatment effect, and low electrochemical oxidation speed. , to achieve the effect of improving the efficiency of electrolytic catalytic treatment, novel equipment structure and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the accompanying drawings and examples. However, the invention is not limited to the examples given.

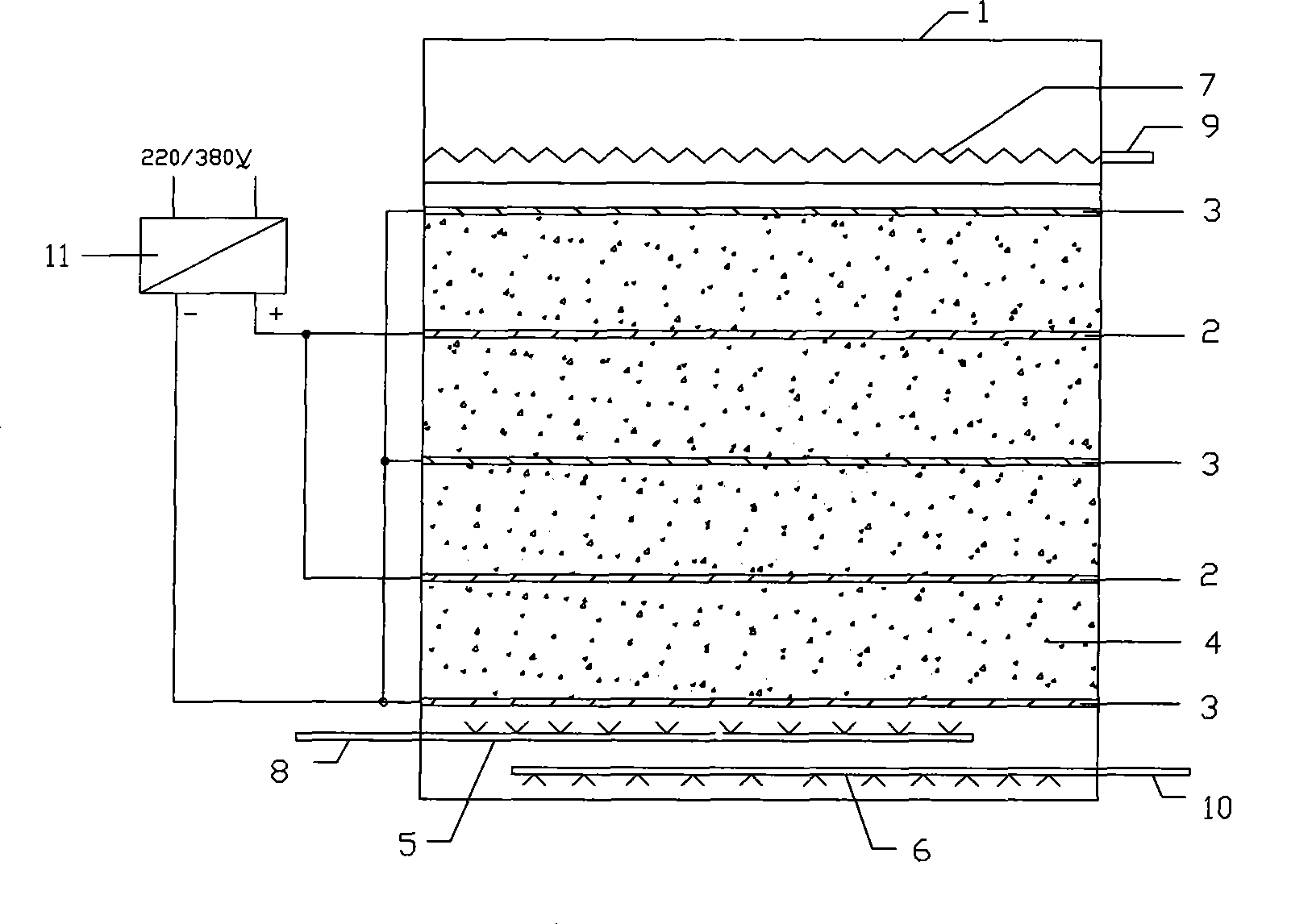

[0029] Such as figure 1 As shown, the horizontal plate multi-dimensional electrode electrocatalytic reactor wastewater treatment equipment of the present invention comprises a device housing 1, a parallel opposite cathode plate 3, an anode plate 2, particles filled between the cathode plate 3 and the anode plate 2 The electrode 4, the water distributor 5 and the water inlet pipe 8 connected thereto, the aerator 6 and the inlet pipe 10 connected thereto, the water outlet weir groove 7, the water outlet pipe 9 and the power supply 11, the cathode plate 3, the anode plate 2 and the power supply respectively Negative and positive connections, the improvement is that the cathode plate 3 and the anode plate 2 are distributed with a number of through holes (not shown in the figure), and the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com