Infrared receiver and manufacturing method thereof

A technology of infrared detectors and manufacturing methods, applied in the direction of electric radiation detectors, manufacturing microstructure devices, semiconductor/solid-state device components, etc., can solve problems affecting product performance, reliability and yield, and achieve flattening problems, improve product yield and reliability, and prevent short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

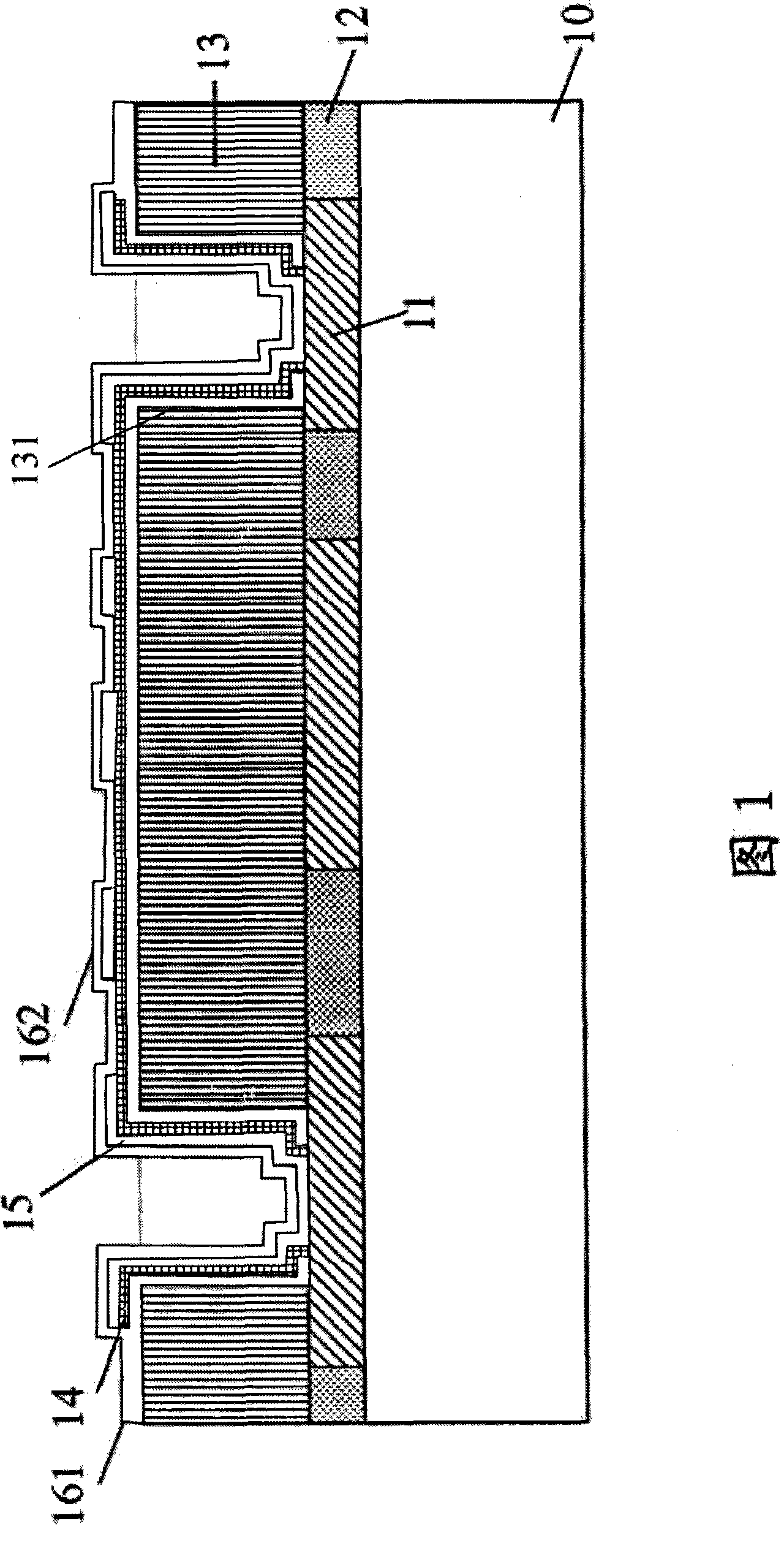

[0026] Please refer to FIG. 1 , which is a cross-sectional view of an infrared detector in a preferred embodiment of the present invention. This embodiment proposes an infrared detector, which can be used in places such as power network security detection, forest fire detection, and human body temperature detection.

[0027] The infrared detector includes a silicon substrate 10 , a metal reflective layer 11 , a dielectric layer 12 , a sacrificial layer 13 , a release protection layer 161 , a sensitive material detection layer 14 , a metal electrode 15 and a release protection layer 162 .

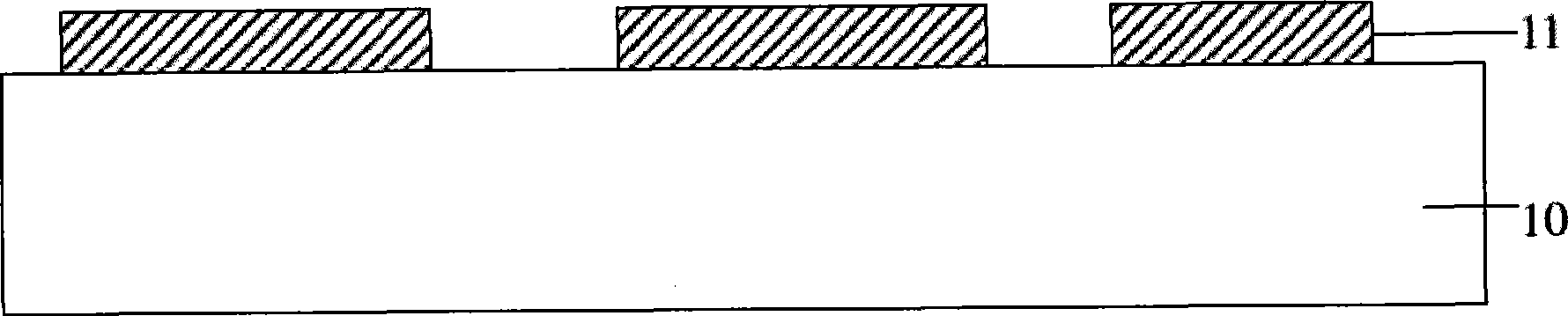

[0028] The metal reflective layer 11 is deposited on the silicon substrate 10, and grooves are carved by photolithography, etching and other processes to form a metal reflective pattern. Its function is to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com