Rubbing method and method of fabricating liquid crystal display device using the same

A grinding method and grinding roller technology, which are applied in grinding devices, grinding machine tools, manufacturing tools, etc., can solve the problems of reducing the aperture ratio and brightness, and the pattern cannot perform the grinding process normally, and achieve the effect of improving the aperture ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments will now be described in detail with reference to the drawings. For the sake of brevity in description with reference to the drawings, the same or equivalent elements are given the same reference numerals, and descriptions of these elements will not be repeated.

[0044] Hereinafter, the grinding method of the present invention and the method of manufacturing a liquid crystal display (LCD) using the same are explained in detail with reference to the accompanying drawings.

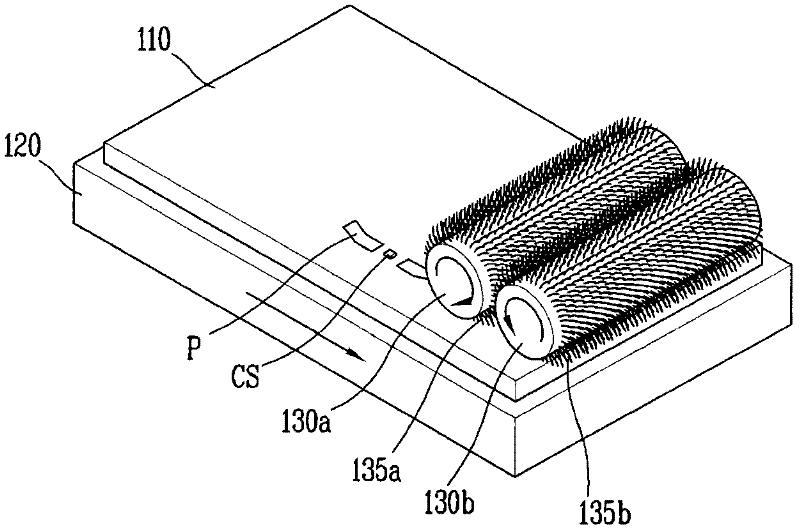

[0045] image 3 It is a perspective view schematically illustrating the polishing process of the present invention.

[0046]As shown in the figure, the grinding device of the present invention includes: a first grinding roll 130a and a second grinding roll 130b, and the first grinding roll 130a and the second grinding roll 130b rotate in different directions to perform two-way grinding; a workbench 120 , the workbench 120 is arranged below the first grinding roller 130a and the second g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com