Well deflection and position gamma measuring nistrument during drilling

A measurement-while-drilling and azimuth gamma technology, which is used in surveying, measuring devices, earth-moving drilling and production, etc., can solve the problem of losing the best time for oil and gas layers, unable to capture the information of the caprock at the top of the reservoir in time, and unable to obtain the well deviation in time. and other problems to achieve the effect of geosteering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

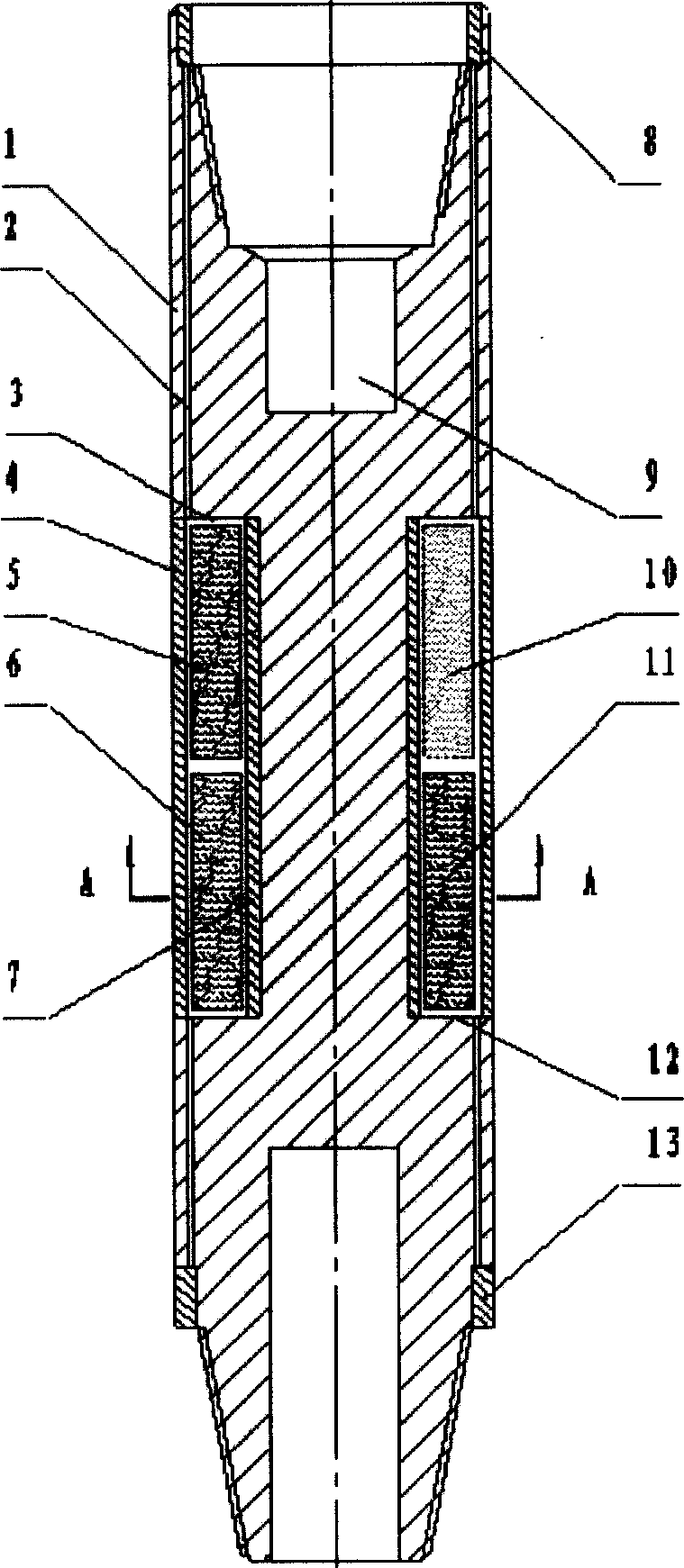

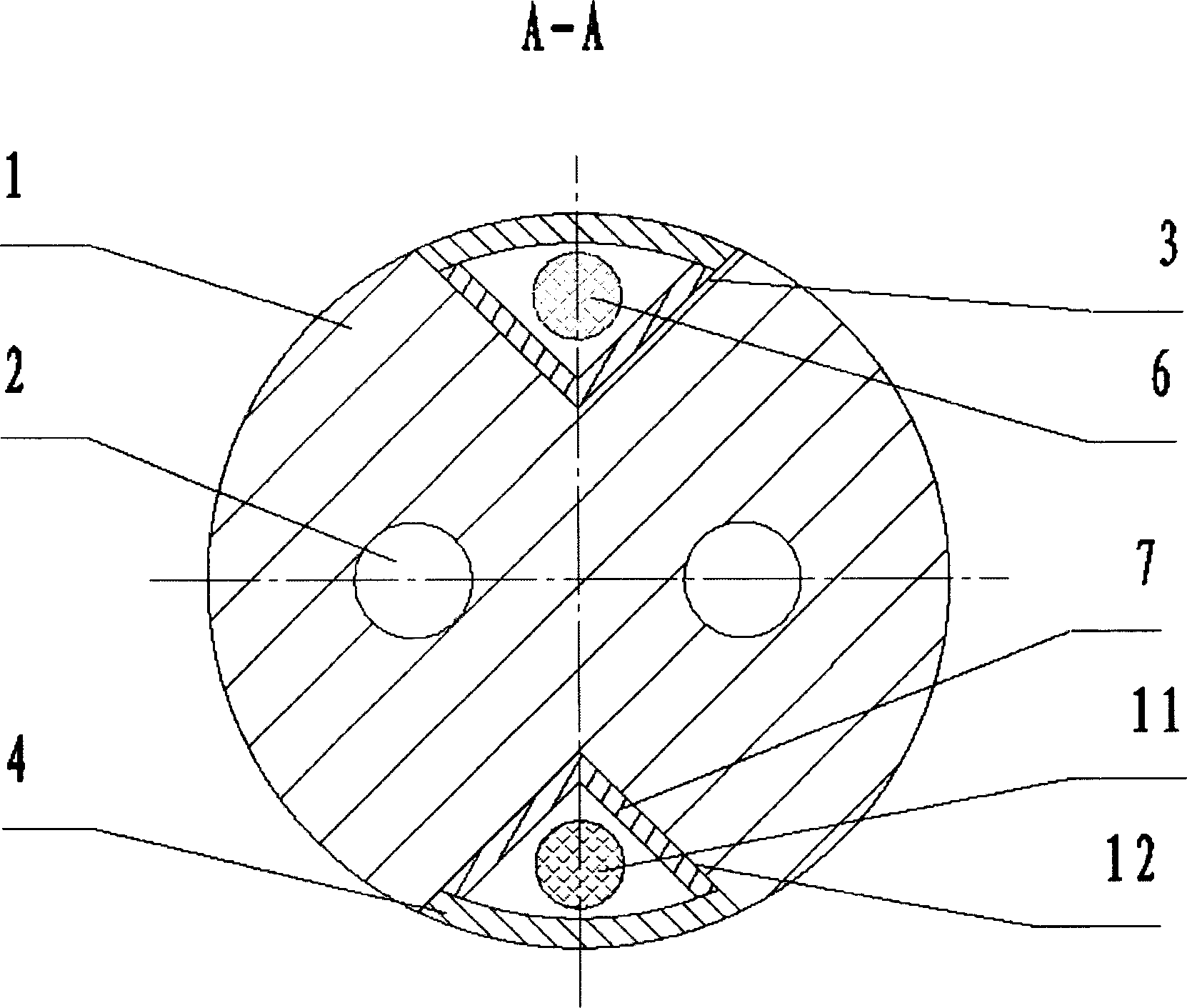

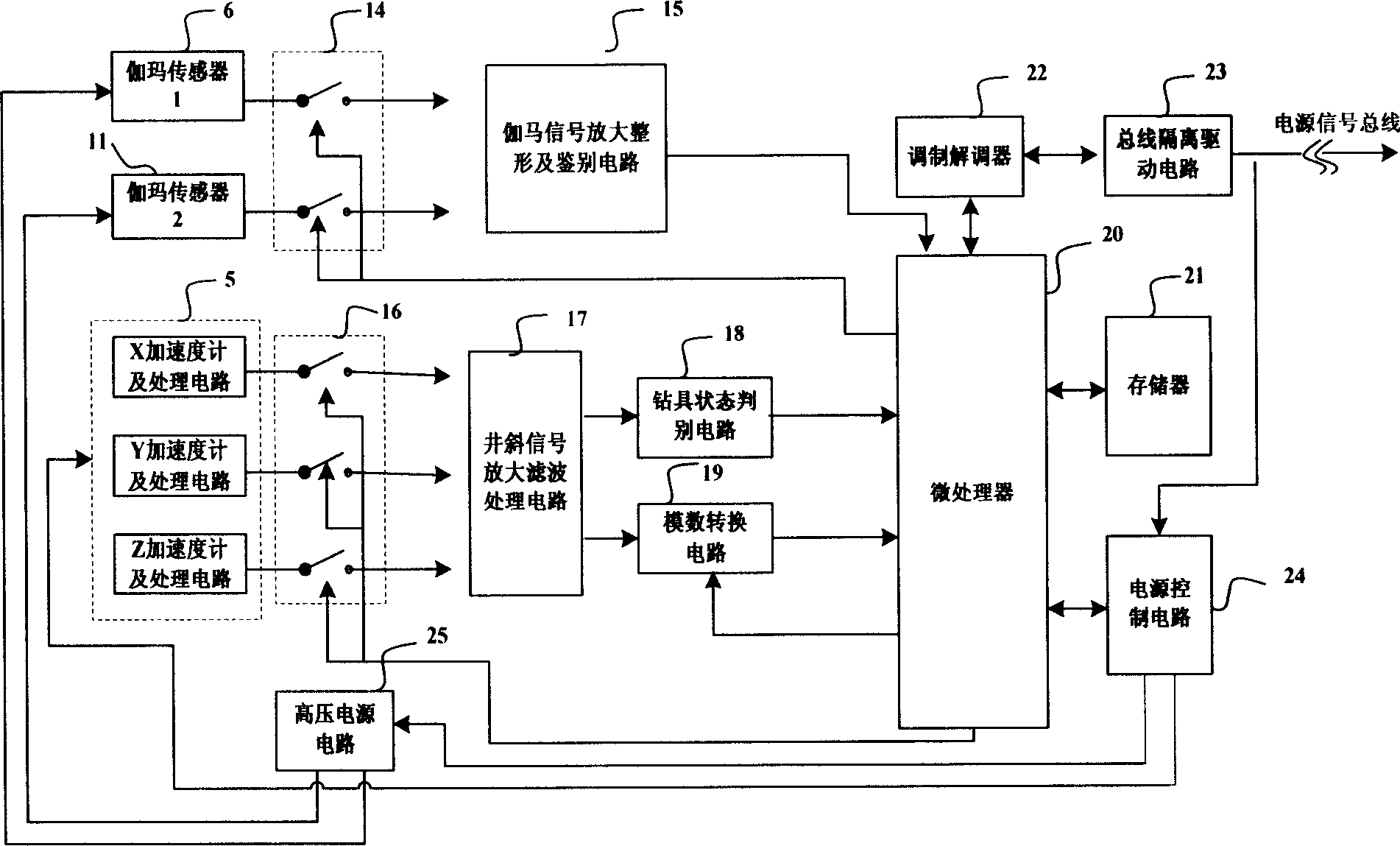

[0023] Now combined with the manual figure 1 , 2 and 3, the present invention is further described.

[0024] figure 1 Represents an axial section view of the instrument. The drill collar 1 is used as the installation skeleton of the instrument and a part of the downhole drilling tool, and is located behind the drill bit or the deflection tool. Open a V-shaped groove 3 on any side of the drill collar 1 as the measuring high side of the instrument, and open a V-shaped groove 12 on the other side 180° opposite to it as the measuring low side of the instrument. The surfaces of the V-shaped grooves 3 and 12 are inlaid with a metal shielding layer 7, a triaxial acceleration sensor 5 and a gamma sensor 6 are installed in the V-shaped groove 3, and a gamma sensor 11 and a signal processing circuit module 10 are installed in the V-shaped groove 12 , the high-pressure sealing cover plate 4 is pressed on the outer edges of the V-shaped grooves 3 and 12. An upper slip ring connector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com