While-drilling borehole compensation electromagnetic wave resistivity survey apparatus

A measuring device and electromagnetic wave technology, which is applied in electromagnetic wave detection, electric/magnetic detection for well logging records, wellbore/well components, etc., can solve the problem of high algorithm structure dependence, difficult implementation, and software-focused algorithms Complexity and other issues, to achieve the effect of not affecting the drilling speed, reducing manufacturing costs, and avoiding instrument bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

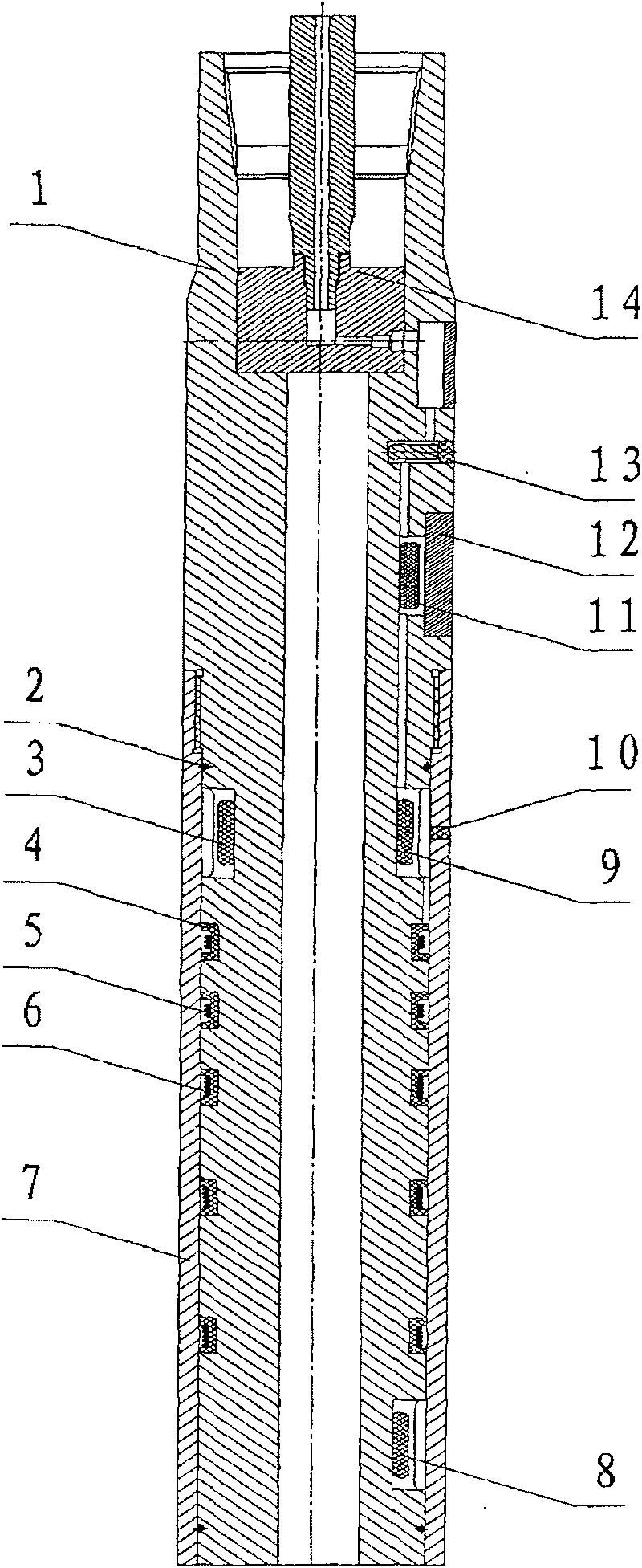

[0025] Now combined with the manual figure 1 , 2 , 3, further describe the present invention.

[0026] figure 1 It shows an axial section view of a measuring device for borehole compensation electromagnetic wave resistivity while drilling. The drill collar 1 is the installation skeleton of the measuring device and a part of the downhole drilling tool. From the middle position of the drill collar 1 to the lower end, a part of the surface is uniformly milled off to form a small-diameter section of the drill collar and a large-diameter section of the drill collar. An external thread is processed at the root of the drill collar thin section, which is used to protect the connection of the sleeve 7 . A sealing ring 2 is installed at the lower part of the external thread and the lower end of the drill collar's thin diameter section to protect the sealing of the inner parts of the sleeve 7 .

[0027] In the middle part of the drill collar narrow section, a plurality of bobbins 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com