Novel method for on-line positioning of superfine milling cutter and workpiece

A technology for micro-milling cutters and workpieces, used in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to online detection, rely on labor, poor applicability, etc., to save configuration time, simple equipment, and positioning speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

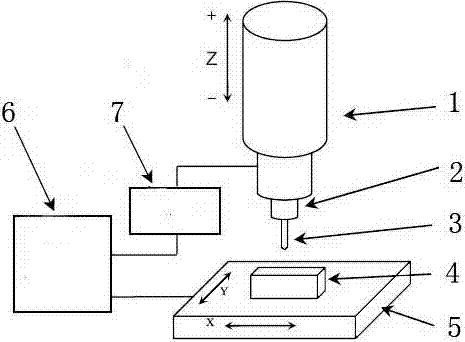

[0022] Such as figure 1 As shown, the present invention is a novel online positioning method for a micro milling cutter and a workpiece, and detects whether the micro milling cutter is in contact with the workpiece based on the change of the voltage signal.

[0023] 1. The detection test is carried out on a self-developed small three-coordinate micro-milling machine tool. The X, Y, and Z axes are all driven by a brushless and slotless linear servo motor platform, and a linear grating coding measurement system with a resolution of 0.1 μm from RENISHAW is integrated. , which can realize the closed-loop feedback control of the servo motor; the maximum speed of the aerostatic electric spindle is 120,000rpm; the workpiece material is brass, and the cutting tool is a carbide two-edged flat end mill with a milling diameter of 0.1mm.

[0024] 2. The micro milling cutter is clamped in the tool holder of the high-speed spindle. The two ends of the special sensor are respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com