Antirust spraying device on outer surface of steel pipe

A technology of spraying device and outer surface, applied in the field of anti-rust spraying device on the outer surface of steel pipe, can solve the problems of large space occupation, low paint recovery rate, uneven paint film, etc., to save space, improve recovery rate, and reduce beating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

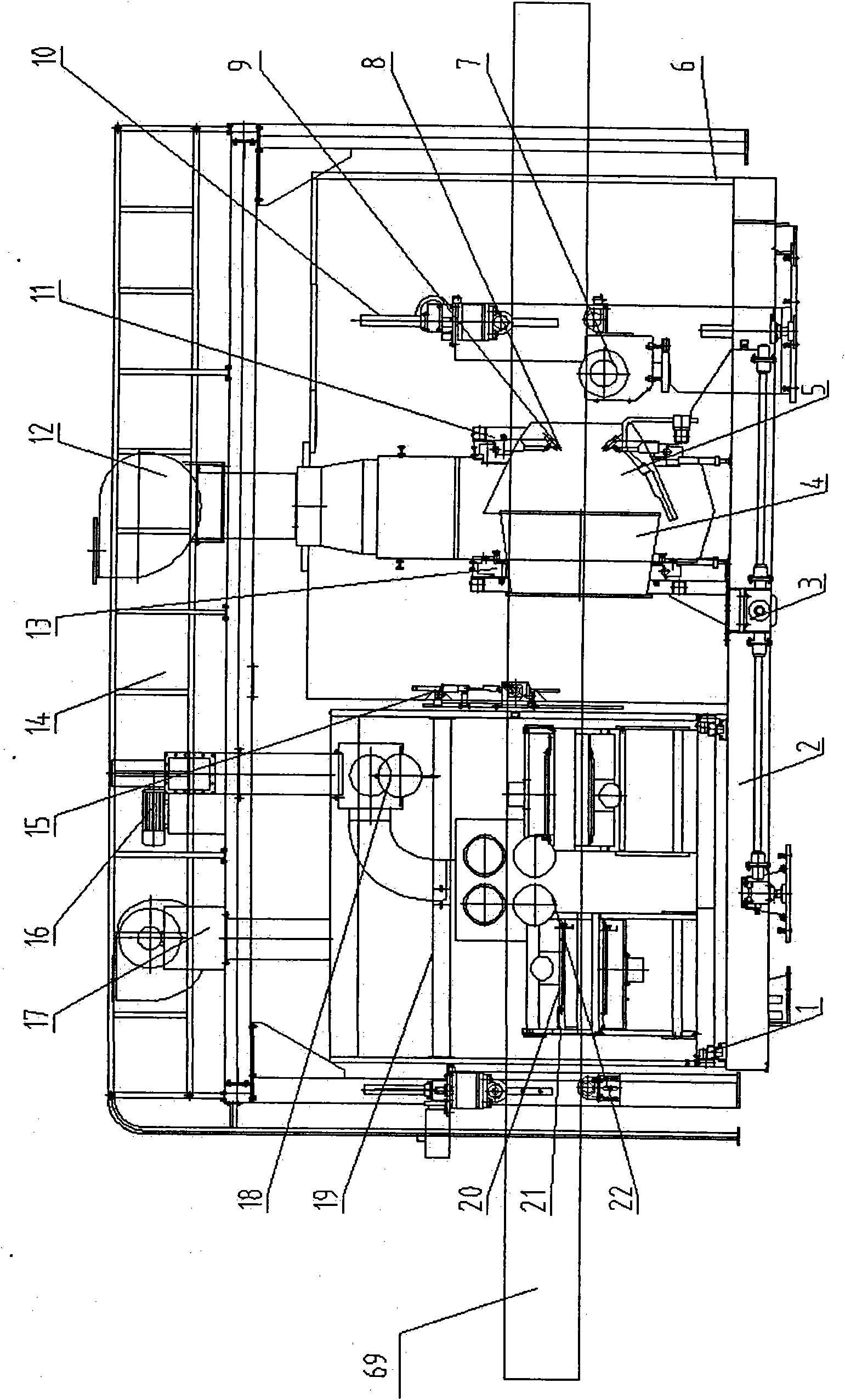

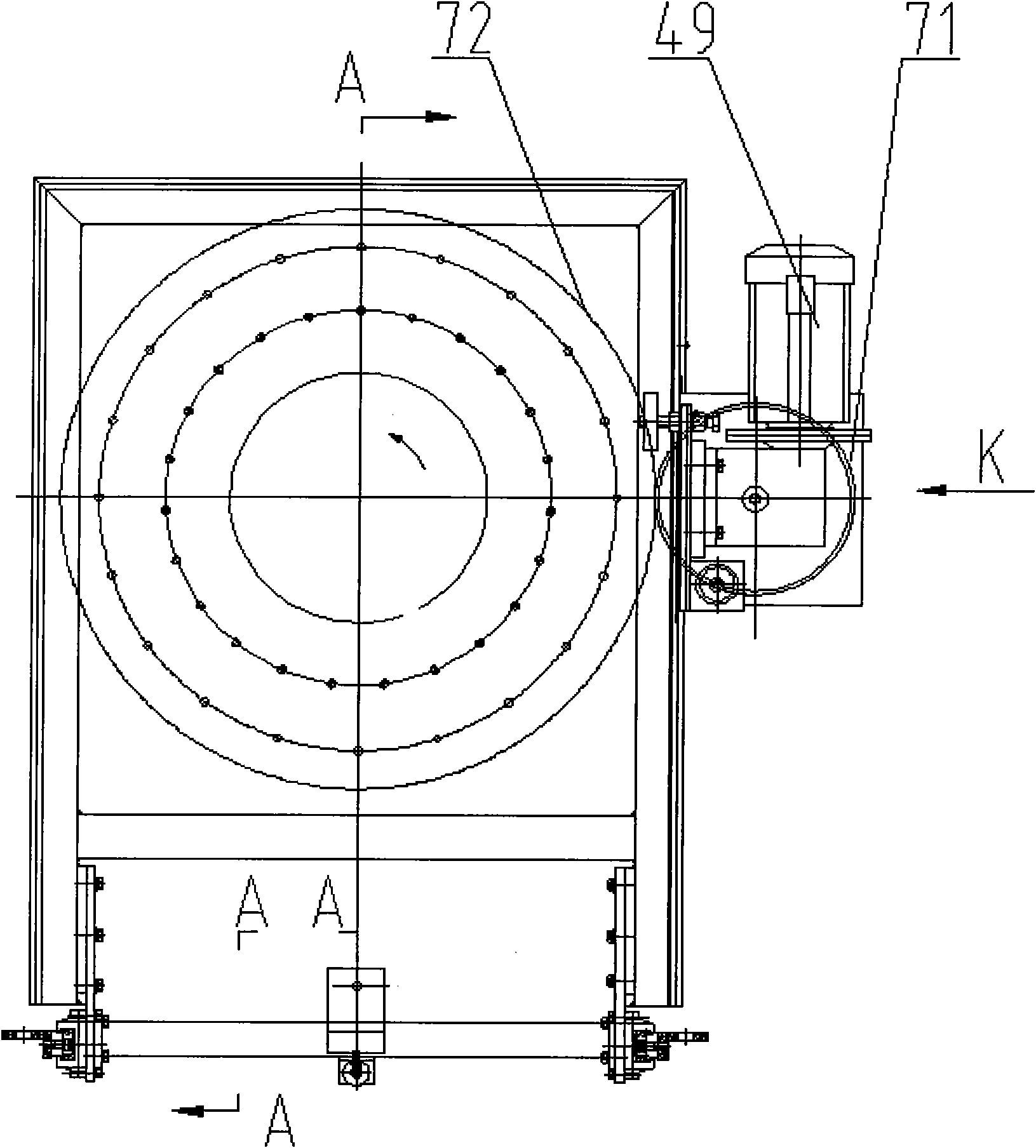

[0042] Such as figure 1 As shown, the present invention includes a lifting mechanism, two sets of UV curing mechanisms with the same structure, a UV paint spraying mechanism, a pressing roller mechanism, a cooling mechanism and a recovery mechanism; wherein:

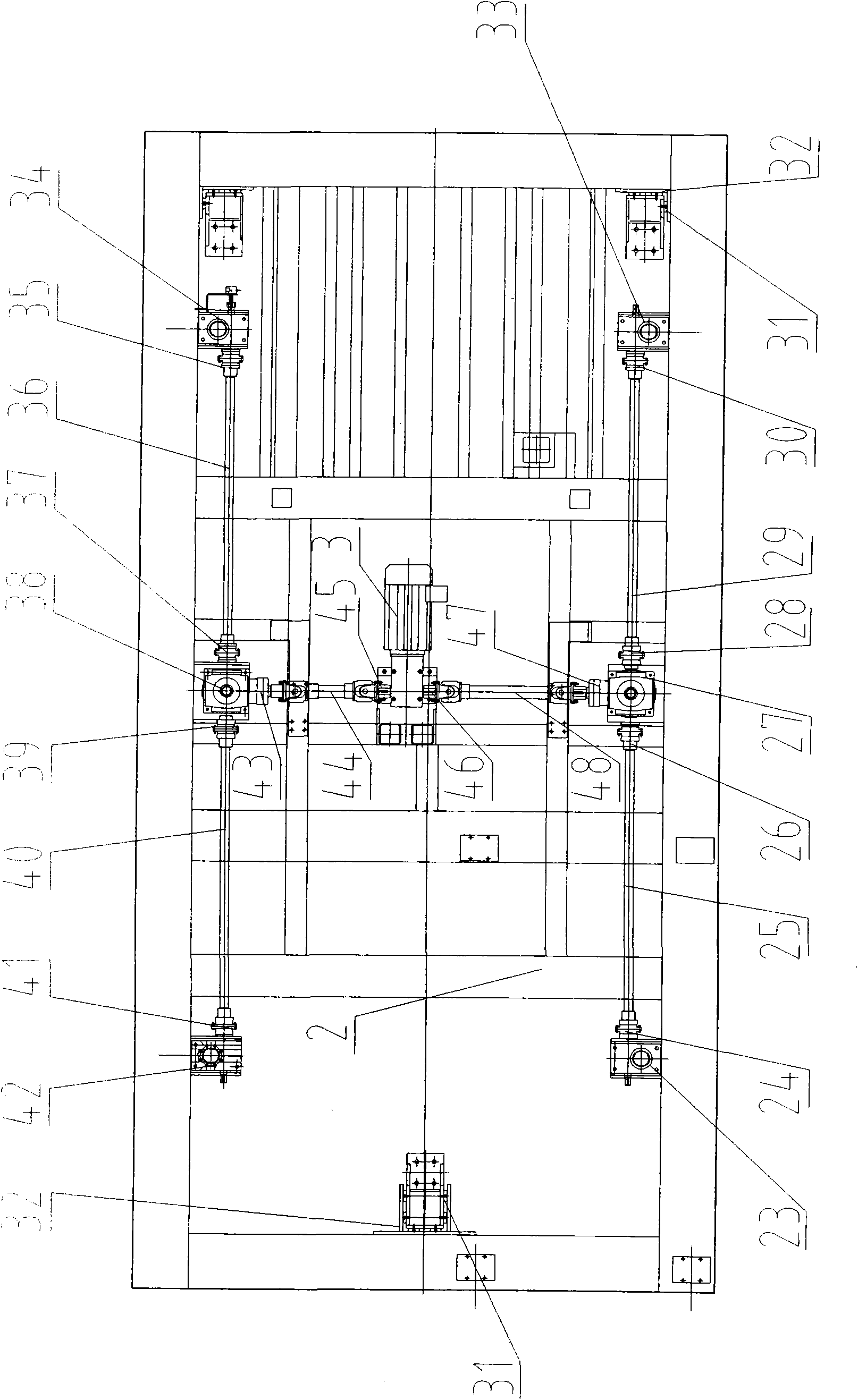

[0043] 1) Lifting mechanism: such as figure 1 , figure 2 , Figure 15 As shown, it includes six screw jacks 23, 27, 33, 34, 38, 42, magnetostrictive displacement sensor 1, lifting frame 2, lifting reduction motor 3 and twelve shaft couplings 24, 26, 28, 30, 35, 37, 39, 41, guide mechanism; the first, second, third screw elevators 23, 27, 33 and the fourth, fifth, sixth screw elevators 23, 27, 33 are symmetrical to the steel pipe 69 center line Distributed on both sides of the steel pipe, the base of each screw lift is connected to the ground through bolts, the vertical output shaft of each sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com