Assembly tooling for fuel tank and operating platform of a heavy truck

A technology for operating platforms and heavy-duty trucks, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as platform assembly can not be maintained level, surface damage of parts, affect appearance and quality, etc., to improve assembly efficiency and assembly Quality, damage reduction, and improved assembly consistency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

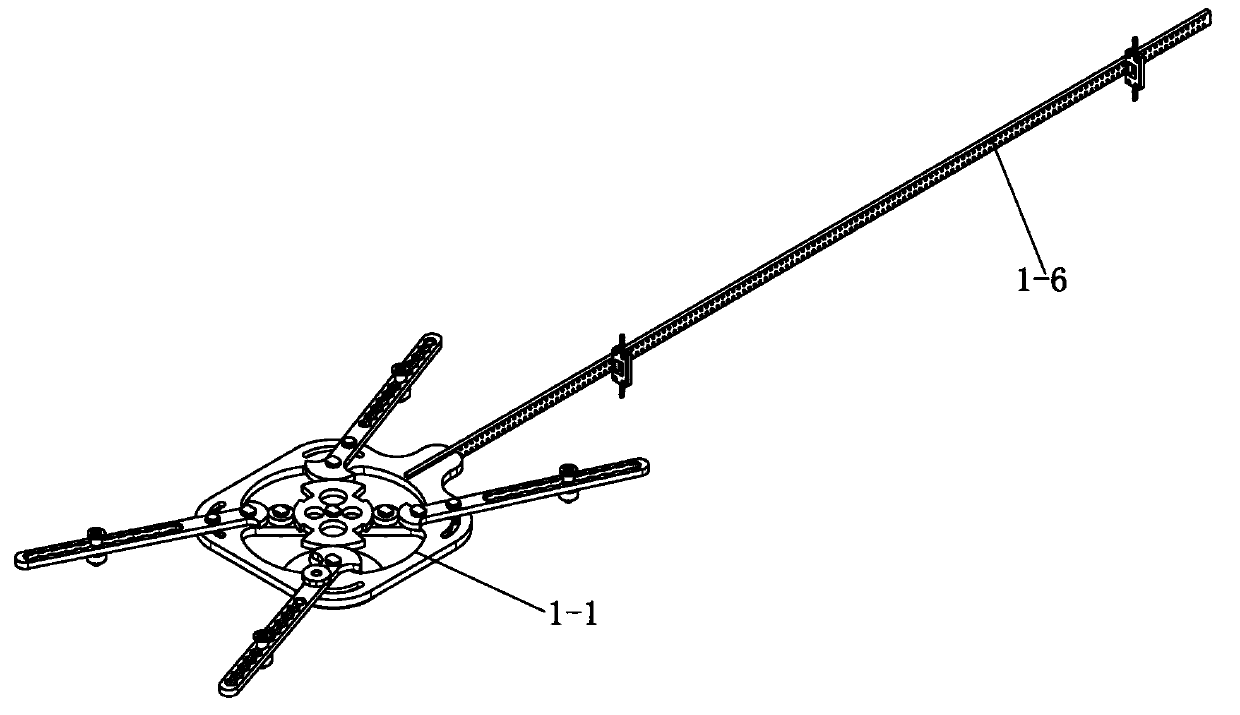

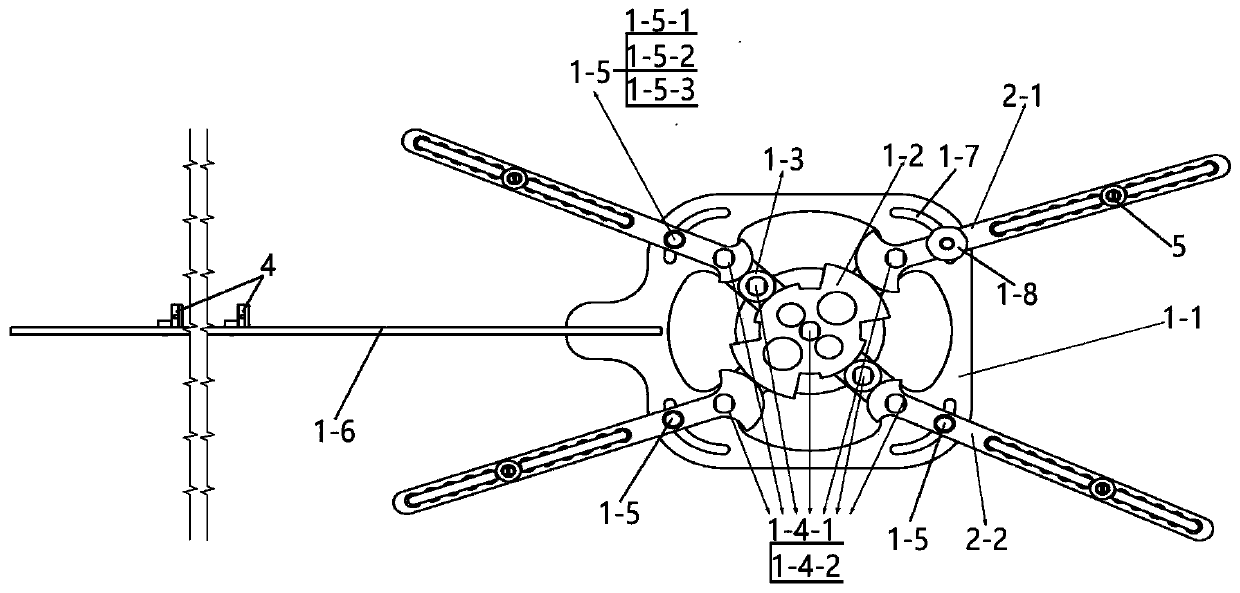

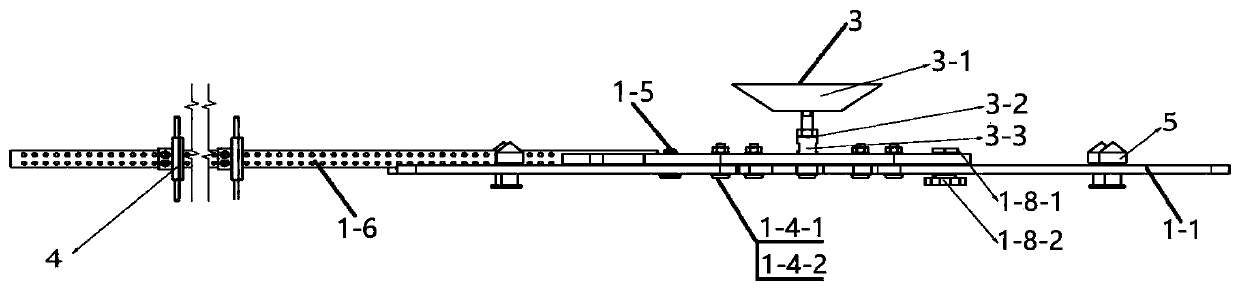

[0041] Such as figure 1 , figure 2 , image 3 , which is an assembly tooling for a fuel tank of a heavy truck and an operating platform disclosed in the present invention, comprising a fixedly connected adjustment mechanism bracket 1-1 and a vernier bracket 1-6, an adjustment mechanism bracket 1-1 and a vernier bracket 1-6;

[0042] The main gear 1-2, 2 secondary gears 1-3, 2 first rack brackets 2-1, 2 second rack brackets 2-2, and 2 secondary gears are connected in rotation on the adjustment mechanism bracket 1-1 1-3 are spaced 180° on the circumference of the main gear 1-2 and meshed with the main gear 1-2, two first rack brackets 2-1 are spaced 180° on the circumference of the main gear 1-2 and one end is connected to the main gear 1 -2 meshing, 2 second rack supports 2-2 one ends mesh with 2 secondary gears 1-3 respectively; The transmission ratio of main gear 1-2 and second rack support 2-2=main gear 1-2 and Transmission ratio of the first rack bracket 2-1; preferably...

Embodiment 2

[0050] Such as figure 2 , the main gear 1-2 adopts segmented special-shaped gears, and the diameter of the addendum circle where the main gear 1-2 meshes with the first rack bracket 2-1 is larger than the teeth where the main gear 1-2 meshes with the auxiliary gear 1-3 The diameter of the top circle is such that the rotation centers of the two first rack brackets 2-1 and the two second rack brackets 2-2 are all on the distribution circle with the rotation center of the main gear 1-2 as the center. The structures and connections of the rest of the components are the same as in Embodiment 1.

[0051] When the present invention is in use:

[0052] Such as Figure 11 , Figure 12 , when assembling, loosen the manual lock nut 1-8-2, and connect the first rack bracket 2-1 and the second rack bracket 2-2 along the connecting pin shaft 1-4- on the adjustment mechanism bracket 1-1 1 to open, adjust to the corresponding position on the connecting plate of the fuel tank 6, and move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com