Nozzle ring for turbocharger

A technology of turbocharger and nozzle ring, applied in machine/engine, stator, engine components, etc., can solve the problems of inconsistent starting time and angular rotation rate, reduced blade rotation synchronization, affecting engine performance, etc. Achieve the effect of increasing the length and area of contact and mating, simplifying the processing and assembly process, and achieving good rotation consistency and synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

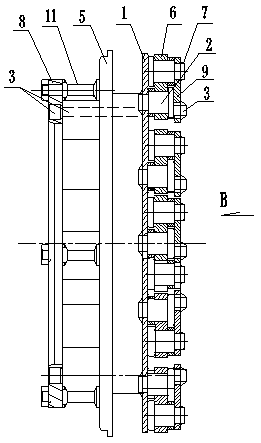

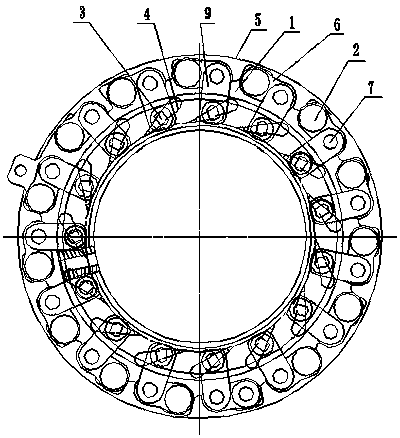

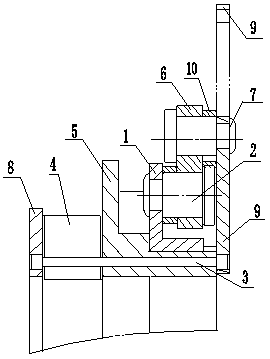

[0019] exist figure 1 , figure 2 , image 3 and Figure 4 Among them, a nozzle ring for a turbocharger includes a lining plate 8, a mounting plate 5 and a shift fork plate 1, and five spacer shafts 11 are arranged between the lining plate and the mounting plate, and the lining plate and the mounting plate There are several blades 4 (fifteen blades in this embodiment) arranged at intervals between the disks. The blades are pointed pear-shaped. Under the action, it can rotate concentrically (left and right) around the mounting plate. The original plate-shaped fork plate is designed as a T-shaped bushing, and the original plate-shaped fork plate is made into an integral T with flange sleeve. The shape of the fork plate (such as Figure 4 shown), so as to increase the axial matching distance between the fork plate and the mounting plate, and increase the contact length and area of the fork plate and the outer surface of the mounting plate, so that the rotation stability of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com