Copper roll type method of making commutators

A manufacturing method and commutator technology, applied in commutator manufacturing and other directions, can solve the problems affecting the performance of the motor, large radial runout of semi-finished products, poor roundness of the commutator, etc. Good degree of stability, reducing the effect of dynamic unbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

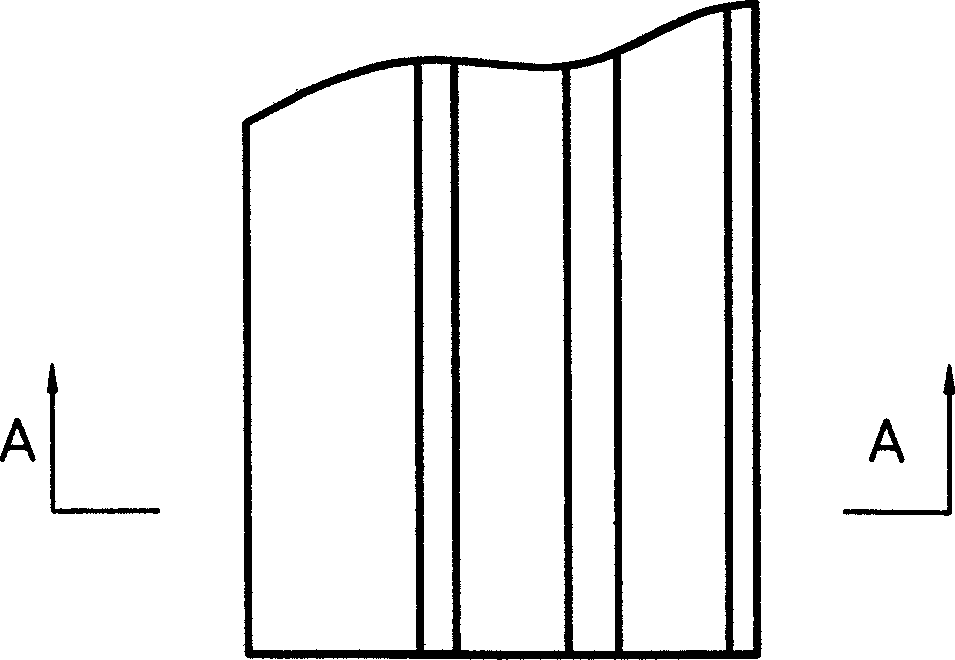

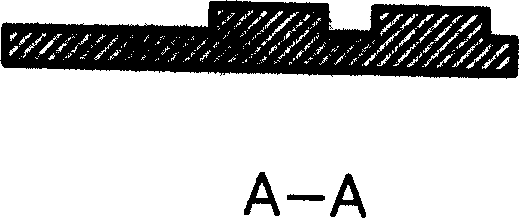

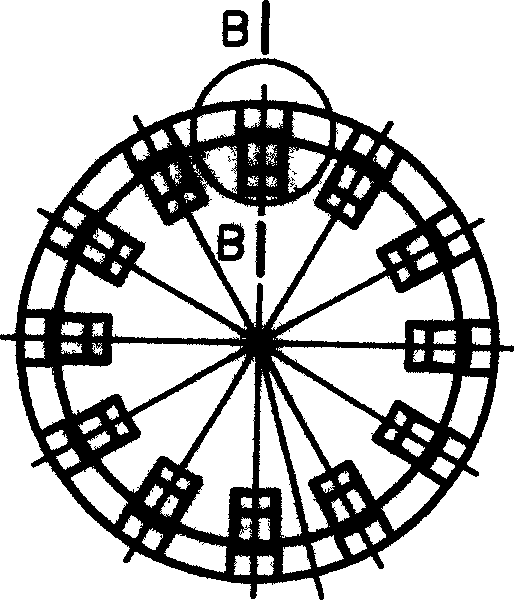

[0016] The copper coil type manufacturing method of the commutator of the present invention comprises successively wire rolling, drawing, annealing, and punching, pressing (adding molding compound), curing, reaming, turning the outer circle, milling grooves, sanding, polishing and other processes, the punching process is punching the annealed wire rod into an annular commutator segment group (punched by a 10-ton punch press). like image 3 shown.

[0017] Because the wire drawing process in the original commutator’s slice-row manufacturing method is to draw the wire into a wire with an “I” shape in cross section, and then punch it into a single commutator piece with a dovetail-shaped longitudinal section, add The molding compound is pressed and solidified, so that the contact area between the commutator piece and the molding compound is small, that is, the adhesion between the commutator piece and the molding compound is small, so that the commutator made is easy to operate d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com