WEDG device for on-line electrode manufacturing in micro electric spark machining

A wire electrode grinding and EDM technology, which is applied in the direction of accessory devices, grinding/polishing equipment, grinding machines, etc., can solve the problems affecting the surface quality of fine electrodes and the influence of precision and dimensional consistency, and achieve small runout and smooth motion. silk smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

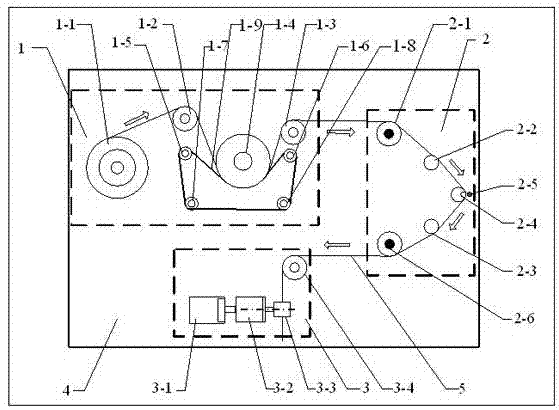

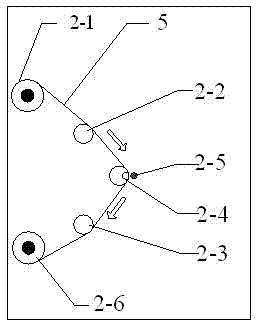

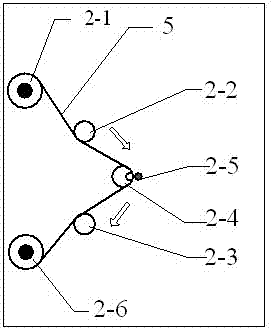

[0016] Specific implementation mode one: as figure 1 , figure 2 , image 3 As shown, it is composed of a wire feeding mechanism 1, a processing discharge mechanism 2, a wire receiving mechanism 3, a base 4, and an electrode wire 5;

[0017] The wire feeding mechanism 1 is driven by a stepping motor for the wire storage barrel 1-1, the first guide wheel 1-2, the second guide wheel 1-3, the pressure wheel 1-4, the first belt runner 1-5, and the second belt The runner 1-6, the third belt runner 1-7, the fourth belt runner 1-8, and the belt 1-9 are composed; the stepper motor drives the wire storage drum 1-1 and is arranged on the first guide wheel 1-2. On the left side, the pressure roller 1-4 is arranged on the lower right side of the first guide roller 1-2, the second guide roller 1-3 is arranged on the upper right side of the pressure roller 1-4, the first belt runner 1-5 and the second The belt runners 1-6 are respectively arranged on both sides of the pressure roller 1-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com