Gear grinding processing method

A grinding process and grinding technology, applied in the direction of belts/chains/gears, gear teeth, components with teeth, etc., can solve the problem of reducing gear radial runout and tooth pitch deviation, radial runout and tooth pitch deviation Unqualified and other problems, to achieve the effect of reducing radial runout and tooth pitch deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Grind m using the gear grinding processing method provided by the present invention n 5.5z54, the steps are as follows: divide the teeth of the gear to be ground into three consecutive groups in the circumferential direction, each group has 18 teeth, and then the teeth in each group are sequentially divided into 9 subgroups, each Each subgroup has 2 teeth; when grinding, first grind the first subgroup in each group in sequence, then grind the second subgroup in each group in sequence, and then grind the group in sequence The third subgroup of, and so on, in this way, each subgroup is ground in sequence, and the cycle is repeated until the grinding of each tooth reaches the design standard.

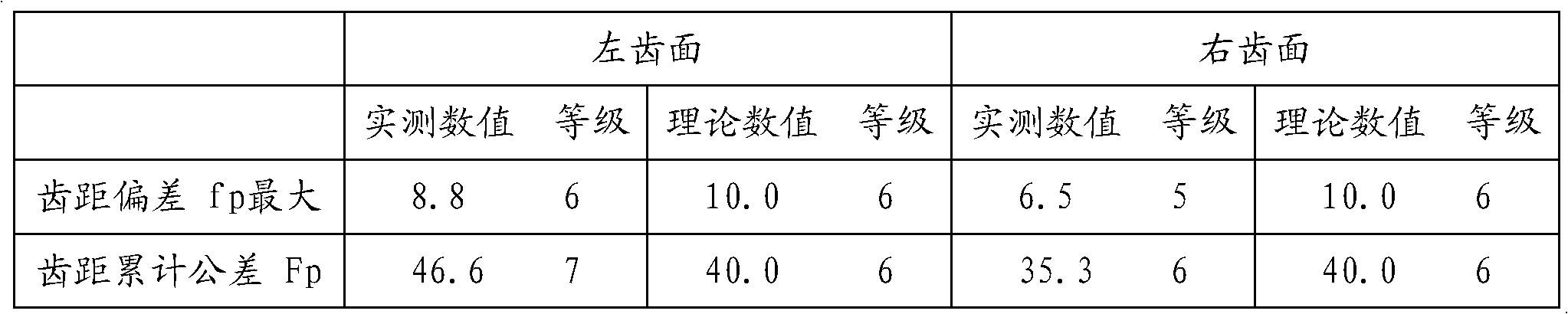

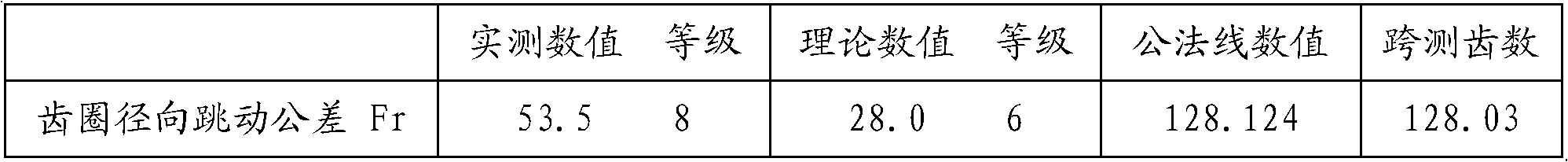

[0022] Table 5 shows the m ground using the gear grinding method of the present invention n Tooth pitch deviation of 5.5z54 gear; Table 6 is the m grounded by the gear grinding method of the present invention n Radial runout of 5.5z54 gear. By comparing with the prior art grinding resu...

Embodiment 2

[0028] Grind m using the gear grinding processing method provided by the present invention n 5.5z63, the steps are as follows: Divide the teeth of the gear to be ground into seven consecutive groups in the circumferential direction, each group has 9 teeth, and each group of teeth is sequentially divided into 3 subgroups, each subgroup has 3 teeth; when grinding, first grind the first subgroup in each group in sequence, then grind the second subgroup in each group in sequence, and then grind the third subgroup in each group in sequence In this way, each sub-group is ground in sequence, and the cycle is performed until the grinding of each tooth reaches the design standard.

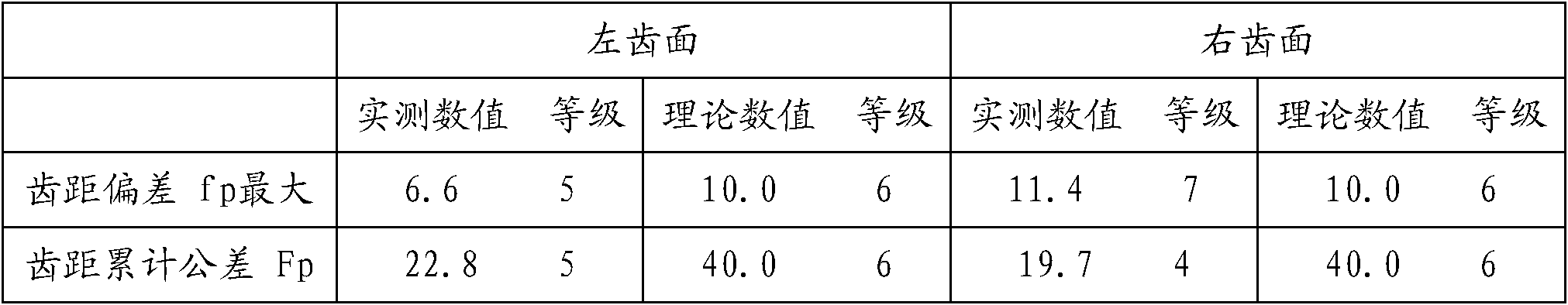

[0029] Table 7 shows the m grounded by the gear grinding method of the present invention n Tooth pitch deviation of 5.5z63 gear; Table 8 is the m measured by the gear grinding method of the present invention n Radial runout of 5.5z63 gear. It can be seen that compared to the prior art grinding results tables 3...

Embodiment 3

[0035] Grind m using the gear grinding processing method provided by the invention n 5.5z43, the steps are as follows: Divide the teeth of the gear to be ground into three consecutive groups in the circumferential direction. The first and second groups have 15 teeth each, and the third group has 13 teeth. Then divide the teeth in the first group and the second group into 3 subgroups in sequence, each subgroup has 5 teeth, and the teeth in the third group are divided into 3 subgroups in sequence, the first subgroup and the first subgroup. The second subgroup has 5 teeth in each subgroup, and the third subgroup has 3 teeth. When grinding, the first subgroup in each group is ground in sequence, and then the first subgroup in each group is ground in sequence. Two sub-groups, and then sequentially grind the third sub-group in each group, and so on, in this way, each sub-group is sequentially ground, and the tool is ground after each sub-group of each group is ground Carry out the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com