Machine tool for grinding composite workpiece under tensioning state

A technology for machining machine tools and workpieces, applied in the field of grinding compound machine tools, can solve problems such as low efficiency and many clamping times, improve machining accuracy, reduce geometric tolerances such as radial runout and roundness, and enhance rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

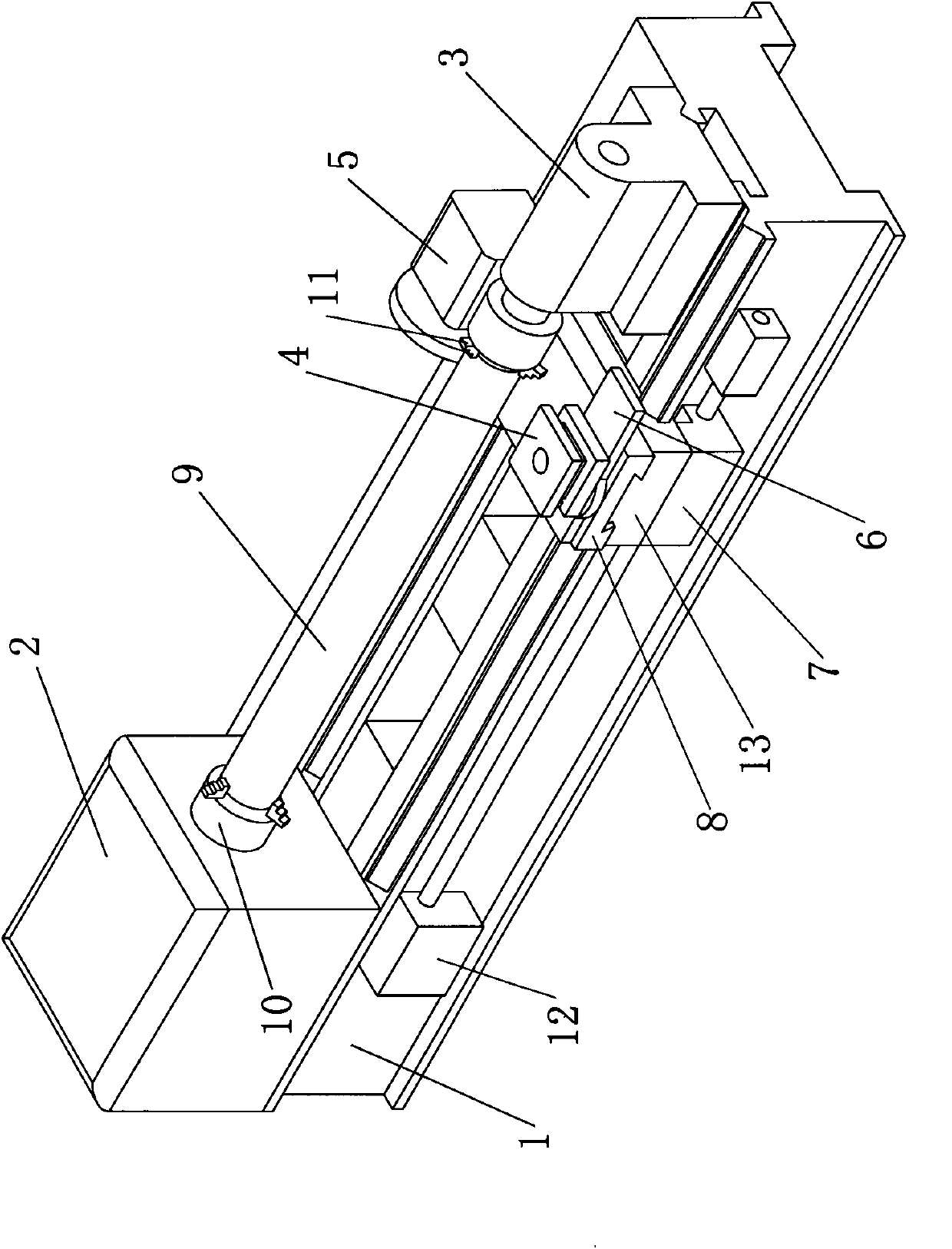

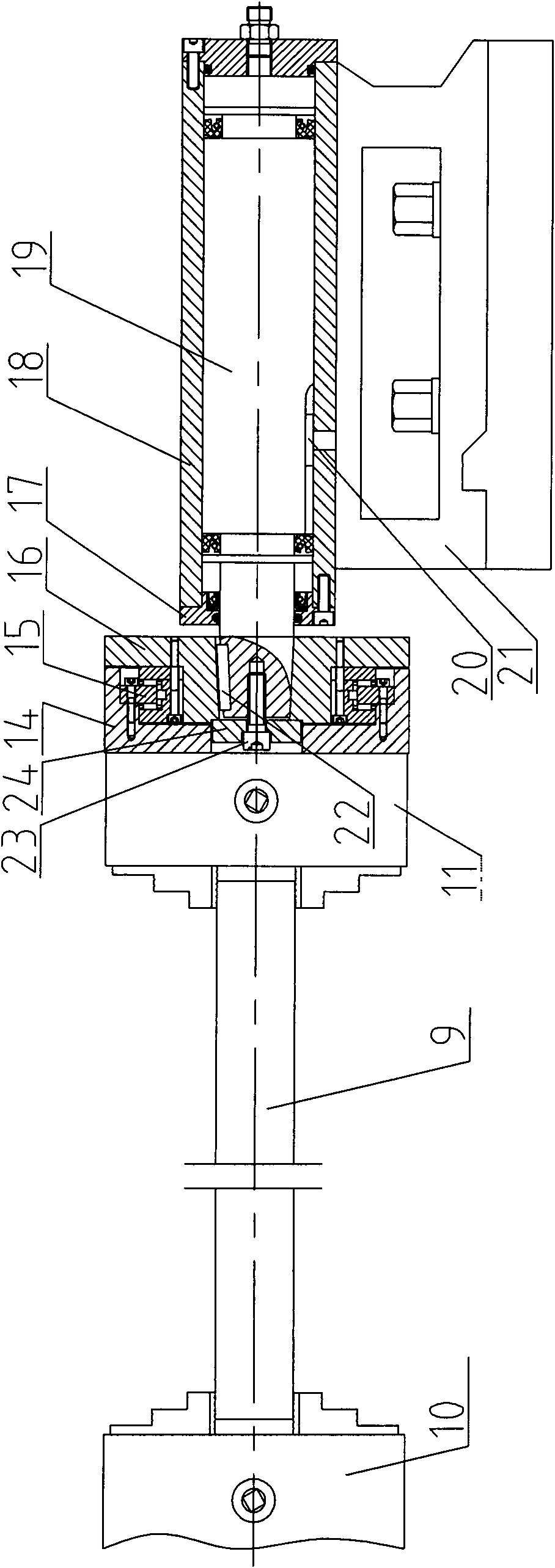

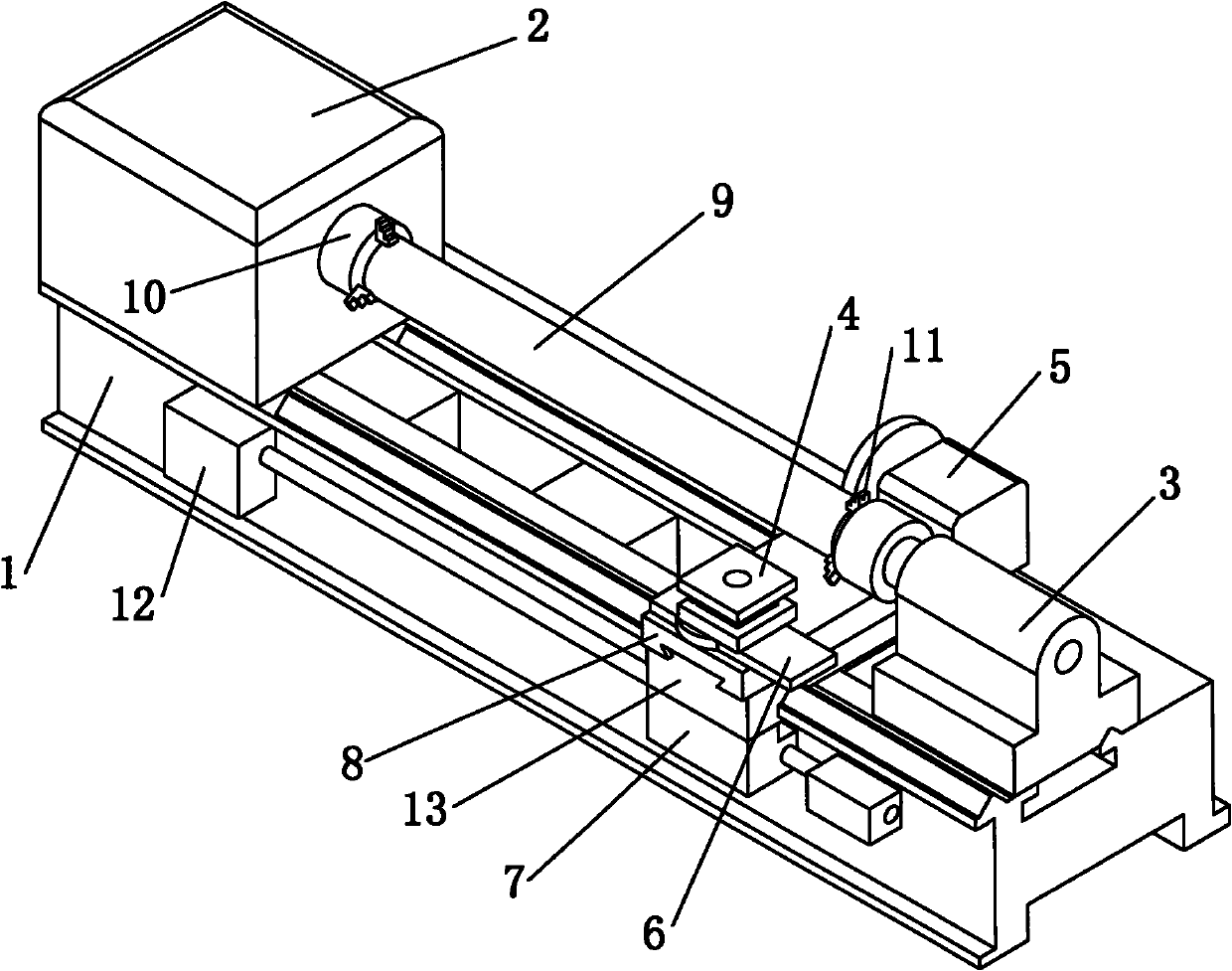

[0014] Such as figure 1 As shown, the processing machine tool under the tensed state of the turning-grinding composite workpiece of the present invention is to increase the grinding device 5 and the tailstock tensioning device 3 on the basis of the existing lathe, mainly including the bed 1, the headstock 2, the feeder Giving box 12, slide board box 7, large plank 13, knife rest 4 and grinding device 5 and tailstock tensioning device 3. Same as the existing ordinary lathes, the bed 1 is equipped with a bedside box 2, a feed box 12, a slide box 7, a tailstock tensioning device 3 and a large carriage 13, wherein the slide box 7 is fed longitudinally The lead screw is connected with the feed box 12, the large carriage 13 is installed on the bed 1 through two longitudinal guide rails, and is rigidly connected with the slide box 7 through bolts, the middle carriage 8 is installed on the large carriage 13 through the dovetail guide rails and is connected with the large carriage 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com