Standing-wave type ultrasonic motor of two driving frequency

An ultrasonic motor and frequency technology, applied in the field of electric motors, can solve the problem that the accuracy of rotor motion needs to be further improved, and achieve the effects of improving driving and control capabilities, reducing radial runout, and improving motion accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

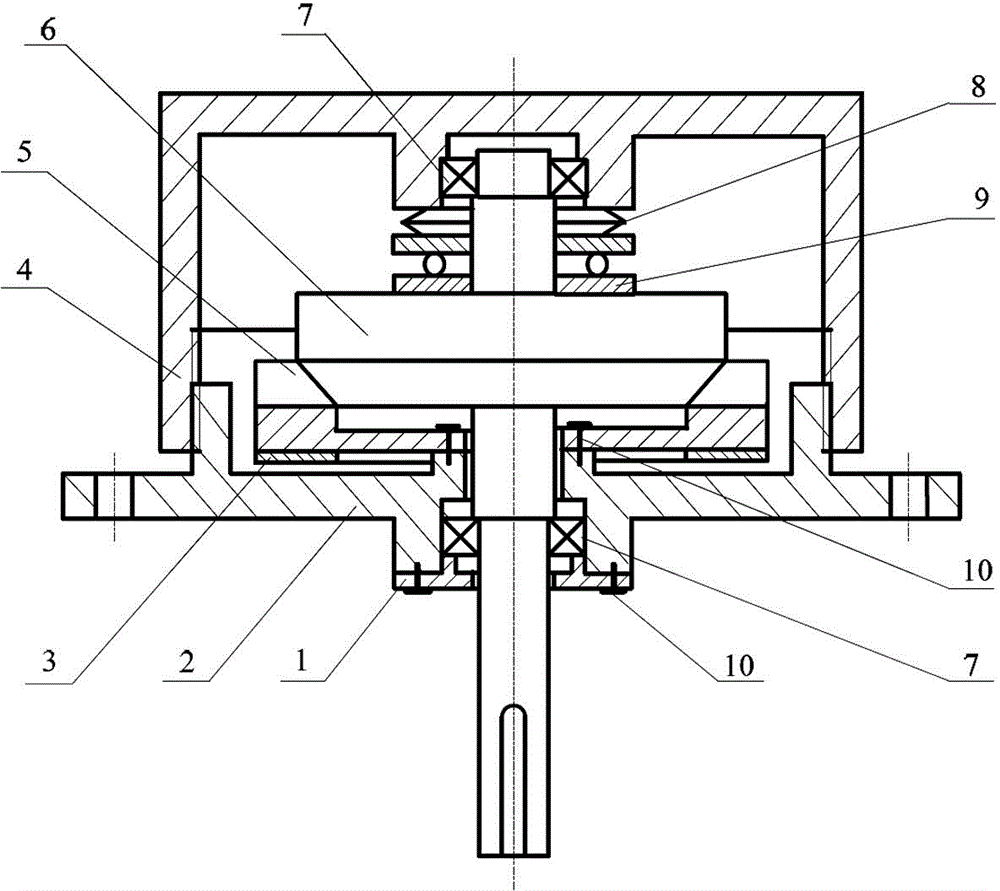

[0031] Such as figure 1 As shown, the present invention includes a base 2 , a pre-tightening case 4 , a stator 5 , a piezoelectric ceramic sheet 3 , a rotor 6 , a thrust bearing 9 and a disc spring 8 .

[0032] The base 2 is a disk-shaped body with a central axis hole. On the top surface of the base 2 disk-shaped body, a central convex edge surrounding the central axis hole and an outer ring for connecting the pre-tightening shell 4 are provided. On the base 2 disk The bottom surface of the shape body is provided with a central ring, and a bearing 7 is housed in the base 2 central ring, and this bearing 7 is generally a radial bearing.

[0033] The pre-tightening shell 4 is a hollow cylindrical cover structure, and the center of the inner top surface is provided with a central ring, and a bearing 7 is also installed in the central ring; the pre-tightening shell 4 is buckled on the base 2, and is connected with the The outer ring on the 2 is connected by thread. The pre-tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com