Preparation method for drive motor shaft of new energy automobile

A new energy vehicle and drive motor technology, applied in the field of metal parts processing, can solve problems such as damage to the metal streamline structure, poor tooth profile strength of internal splines, and splines are prone to fatigue and fracture, and achieve good quality stability and high molding size The effect of high precision and omitting the pickling step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

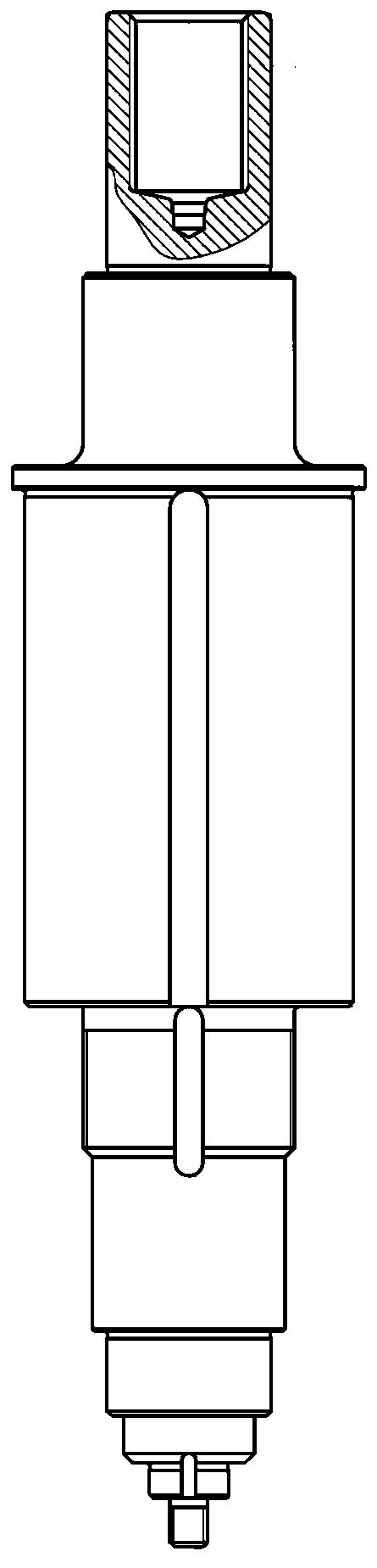

[0031] Now in conjunction with accompanying drawing, the present invention will be further described:

[0032] The preparation method of a new energy vehicle drive motor shaft described in this embodiment comprises the following steps:

[0033] A. Round steel blanking and stress relief: According to the process requirements, cut the round steel billet into the required length and put it into the heating furnace for heating. When the temperature reaches 600°C, stop heating and keep it warm in the furnace for 8 hour, realize stress relief treatment, the round steel billet material described in the present embodiment adopts 20CrMnTi;

[0034] B. Surface sandblasting, phosphating, and saponification treatment; wherein the process of phosphating and saponification treatment is: artificial pretreatment of the workpiece → degreasing and degreasing → washing → rinsing → phosphating → washing → saponification → drying, wherein the phosphating The temperature is 70°C-80°C, the time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com