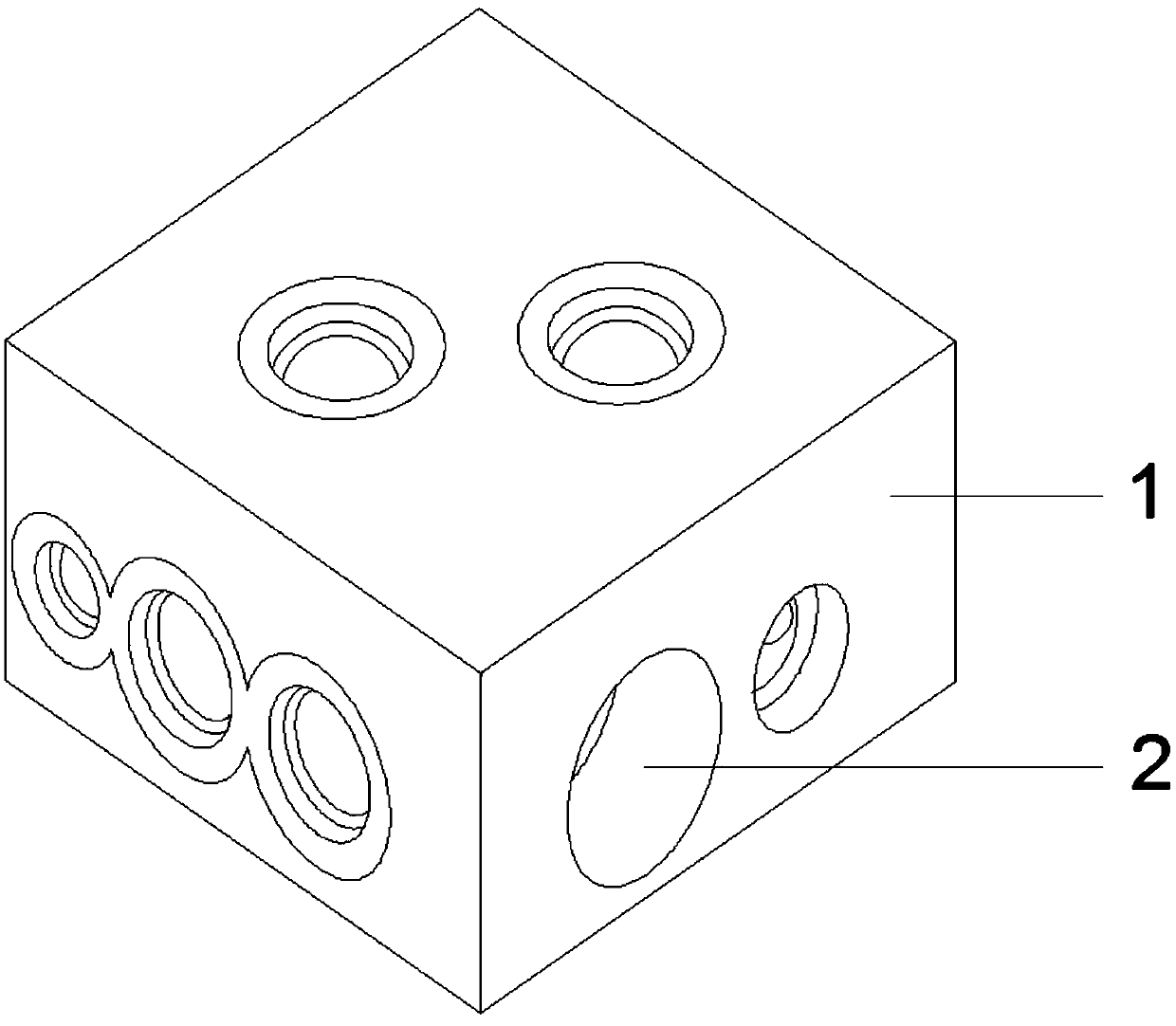

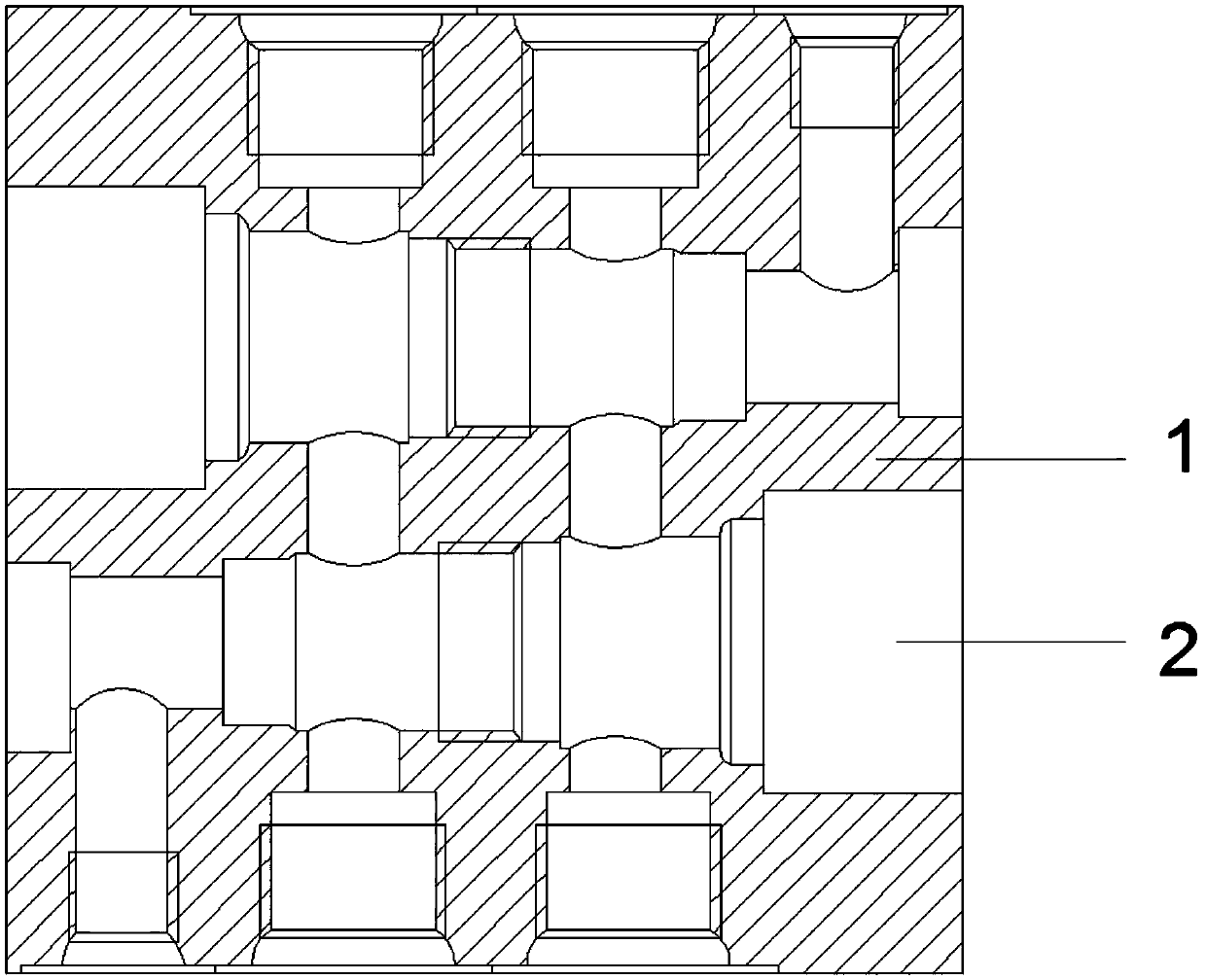

Hydraulic pump valve body processing technology

A processing technology and hydraulic pump technology, applied in the field of hydraulic pump valve body processing technology, can solve the problems of high deburring cost, many processing tools, long processing time, etc., achieve high deburring efficiency, improve efficiency, and reduce processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

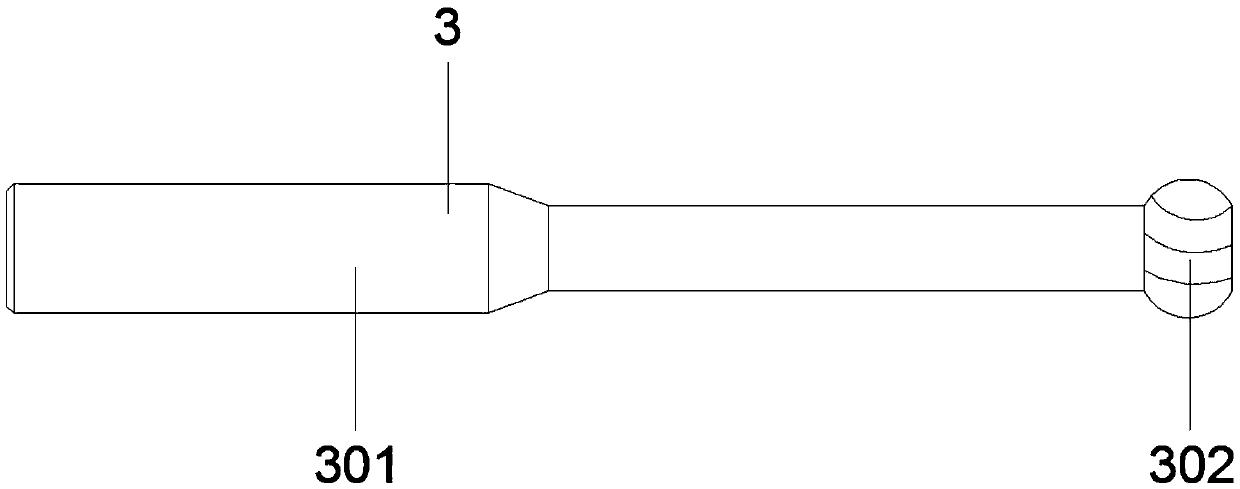

Examples

Embodiment approach

[0050] A process for processing a valve body of a hydraulic pump, comprising the following process steps:

[0051] Step 1: Prepare materials, using square tool steel;

[0052] Step 2: Saw the material, according to the marked length required by the drawing, intercept the tool steel with a marked length of 3-5MM;

[0053] Step 3: Rough milling shape,

[0054] S1: First, fix the tool steel on the clamping tool, mill 1-1.5mm off any one of the upper and lower sides, and take the milled plane as the bottom reference plane of the upper and lower positions of the tool steel;

[0055] S2: Place the bottom datum face down so that it is placed horizontally with the top of the processing machine operating platform, and fix it with a fixed clamping tool, and then mill off 1-2MM from any side of the intercepted tool steel circumference, and get the bottom after measurement The reference plane is at a right angle of 90° to the perimeter of any processed surface, and this is used as the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com