Automatic deburring device capable of realizing accurate compensation

A deburring and automatic technology, which is applied in the direction of grinding drive devices, grinding machine parts, machine tools suitable for grinding workpiece edges, etc., can solve the problems of high labor intensity, component damage, low work efficiency, etc., and achieve cost reduction Inexpensive, guaranteed smoothness and stability, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

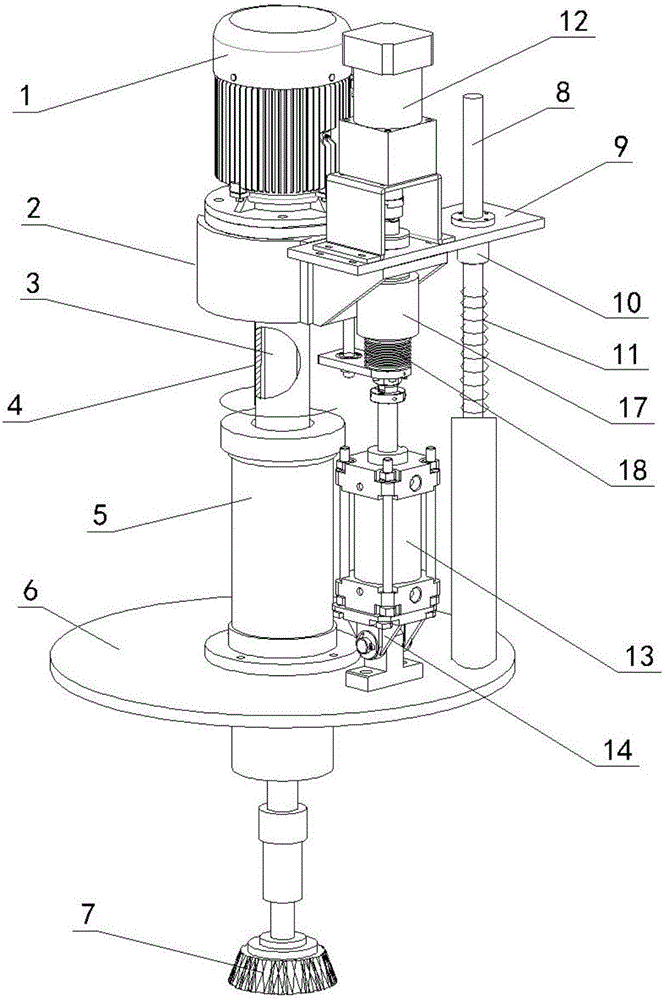

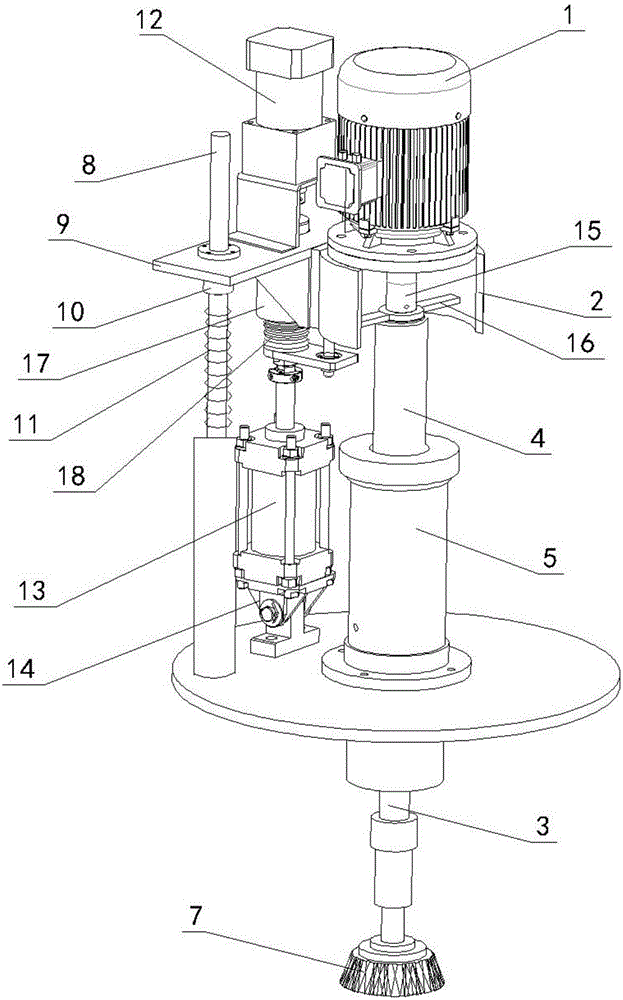

[0032] see figure 1 and figure 2 , the structural form of the automatic deburring device that can be accurately compensated in this embodiment is:

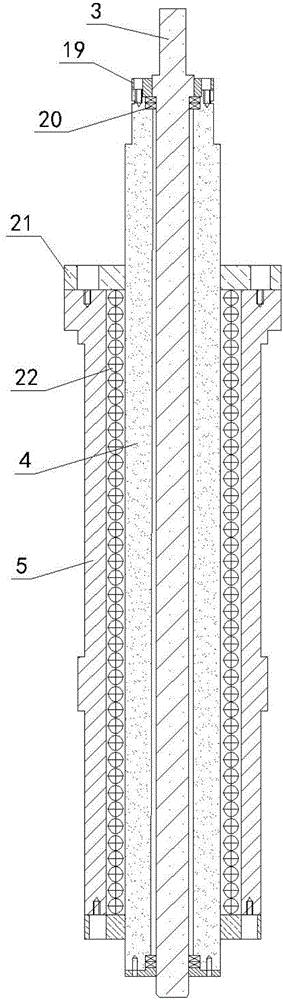

[0033] Fixedly install the rotating electrical machine 1 on the motor mounting base 2, so that the output shaft of the rotating electrical machine 1 is vertically downward, the rotating shaft 3 is fixedly connected with the output shaft of the rotating electrical machine 1 through the first coupling 15, and the rotating shaft 3 runs through the fixed guide seat 5. A brush 7 capable of rotating with the rotating shaft is fixedly installed at the bottom shaft end of the rotating shaft 3 , and the fixed guide seat 5 is installed on the horizontal base plate 6 .

[0034] A hollow guide shaft 4 is set between the rotating shaft 3 and the fixed guide seat 5, the hollow guide shaft 4 is fixedly connected with the motor mount 2, the rotating shaft 3 runs through the hollow guide shaft 4, and can freely rotate in the hollow guide shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com