Deburring device

A technology of deburring and mounting plate, which is applied in the direction of grinding feed motion, grinding machine, grinding machine parts, etc., can solve the problems of high labor cost of staff and low deburring efficiency of products, save labor cost, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

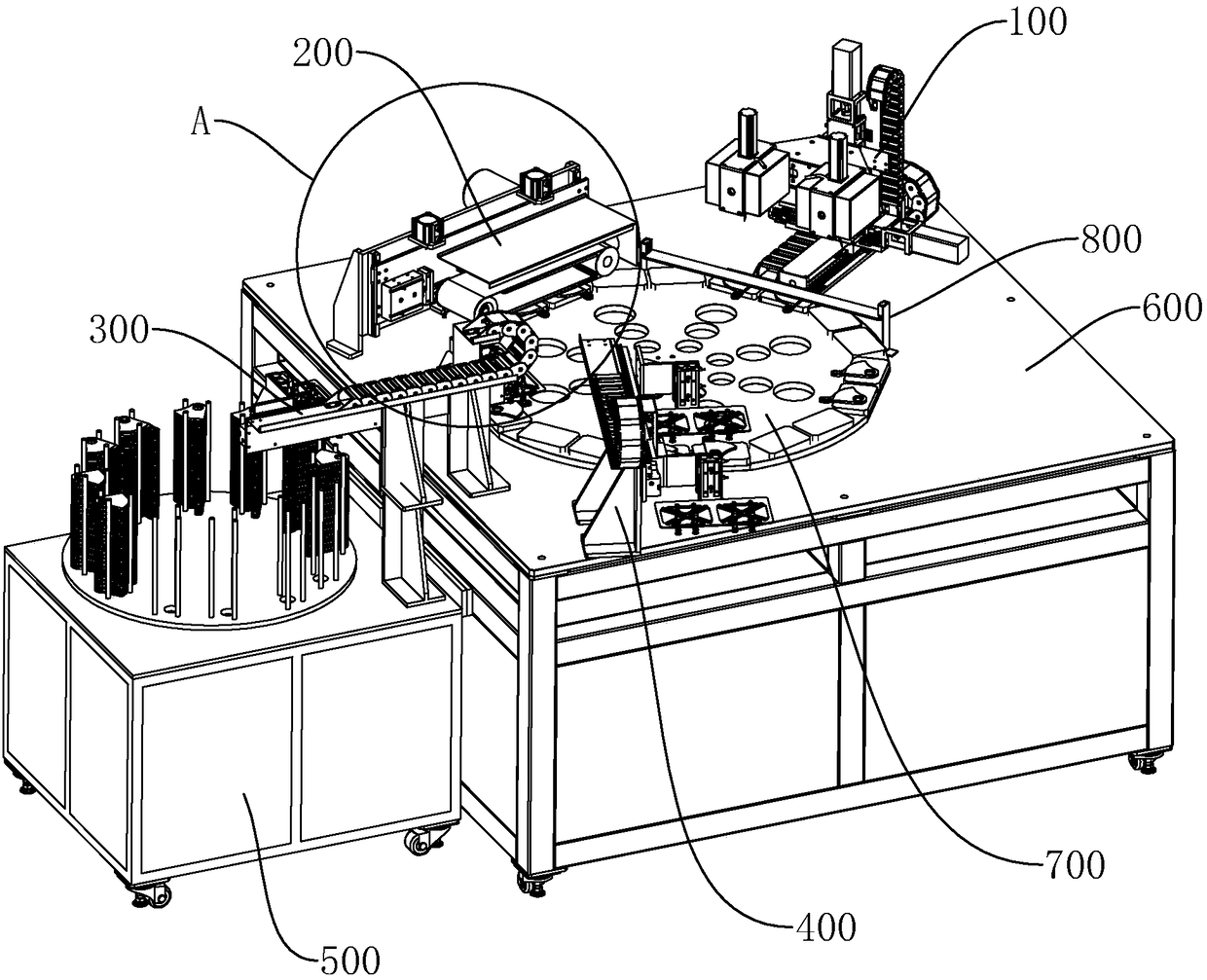

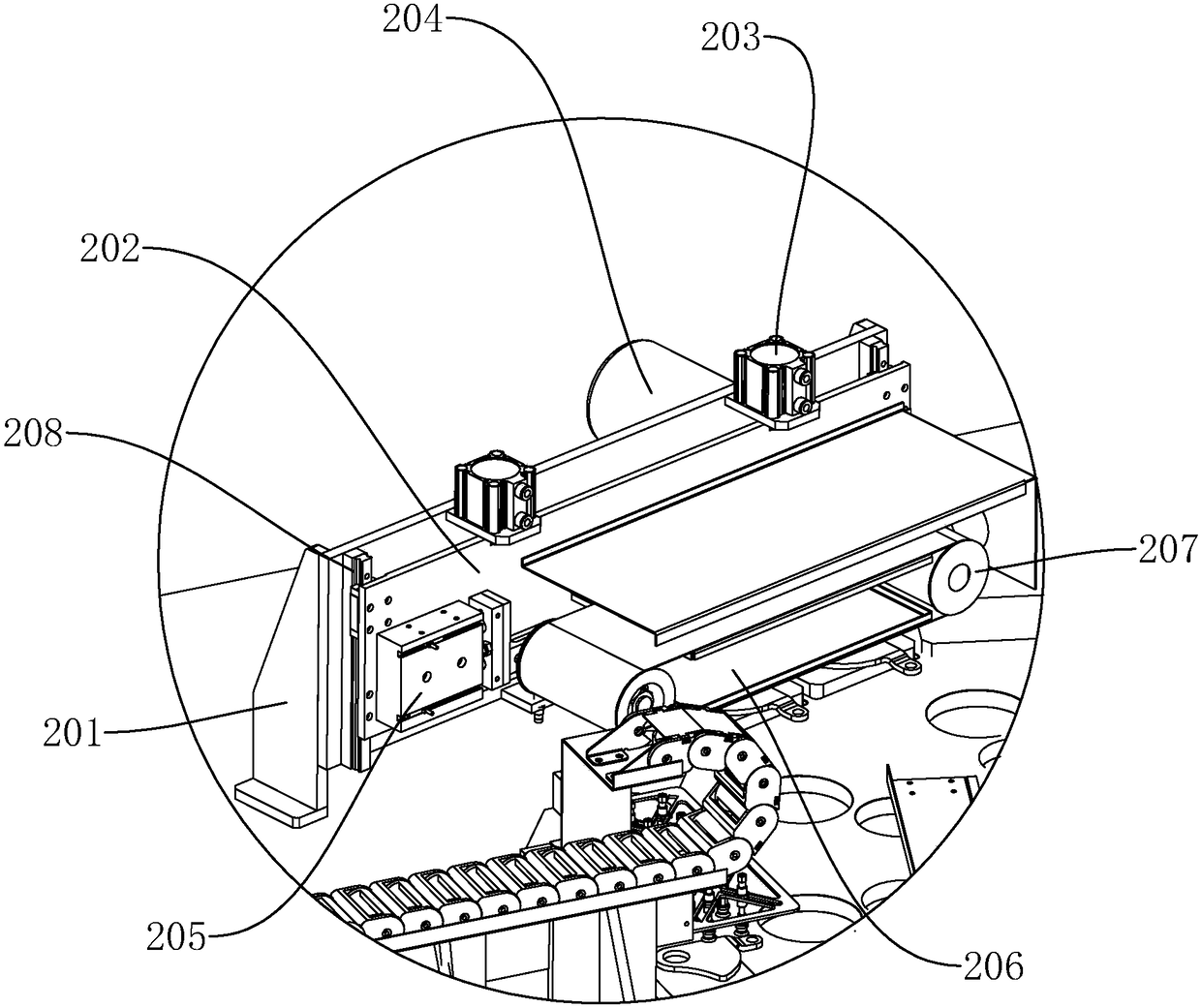

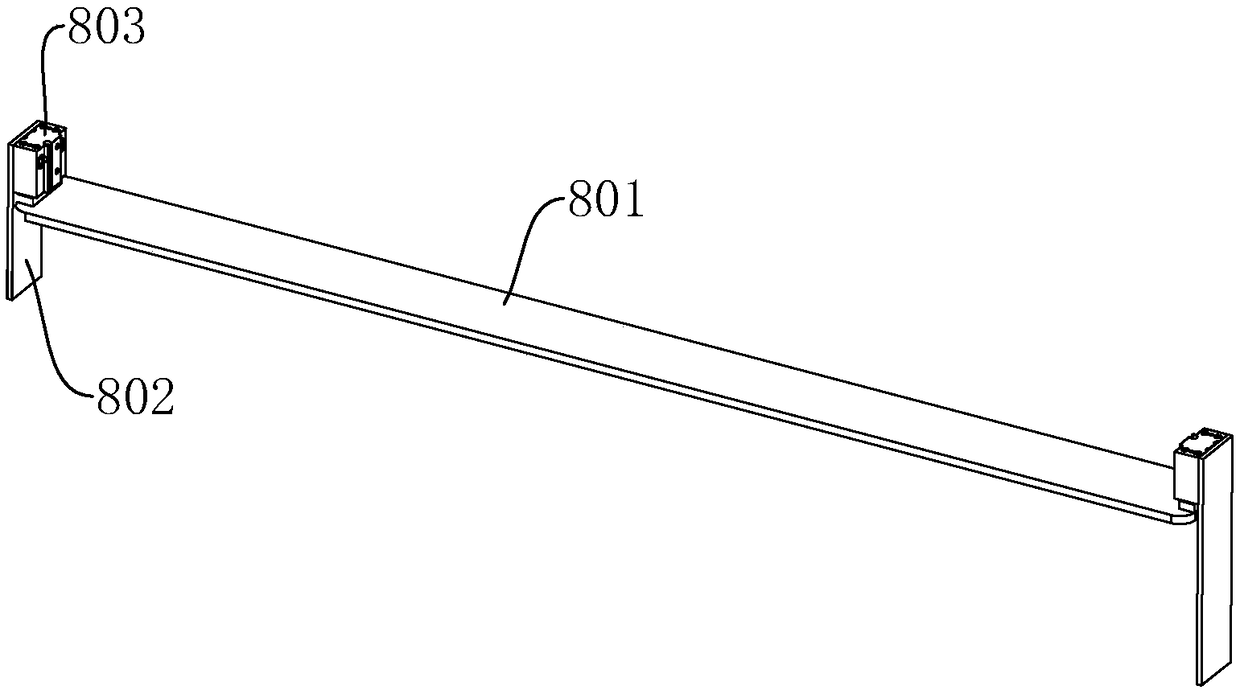

[0020] pass Figure 1 to Figure 5 The deburring device of the present invention will be further described.

[0021] A deburring device, comprising a machine platform 600, a turntable 700, a feeding mechanism 300, a plane grinding mechanism 200, a side grinding mechanism 100, an unloading mechanism 400, and a storage mechanism 500; the turntable 700 is rotatably mounted on the machine platform 600 On, that is, a turntable is installed on the machine platform 600. The turntable has a rotary ring, a fixed ring and a servo motor. The fixed ring is fixed on the machine platform 600. The rotary ring is installed in the fixed ring. Connected with the swivel, so that the servo motor drives the turntable 700 to rotate; the machine table 600 is provided with a loading station, a plane grinding station, a side grinding station and a blanking station distributed along the edge of the turntable 700; The material mechanism 300 is installed on the machine platform 600 and corresponds to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com