High-voltage circuit breaker contact deburring device and deburring method thereof

A high-voltage circuit breaker and deburring technology, which is applied in the direction of grinding machines, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, local cusp discharge, low pass rate, etc., and achieve high surface quality and improved surface quality. High processing efficiency and shape adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

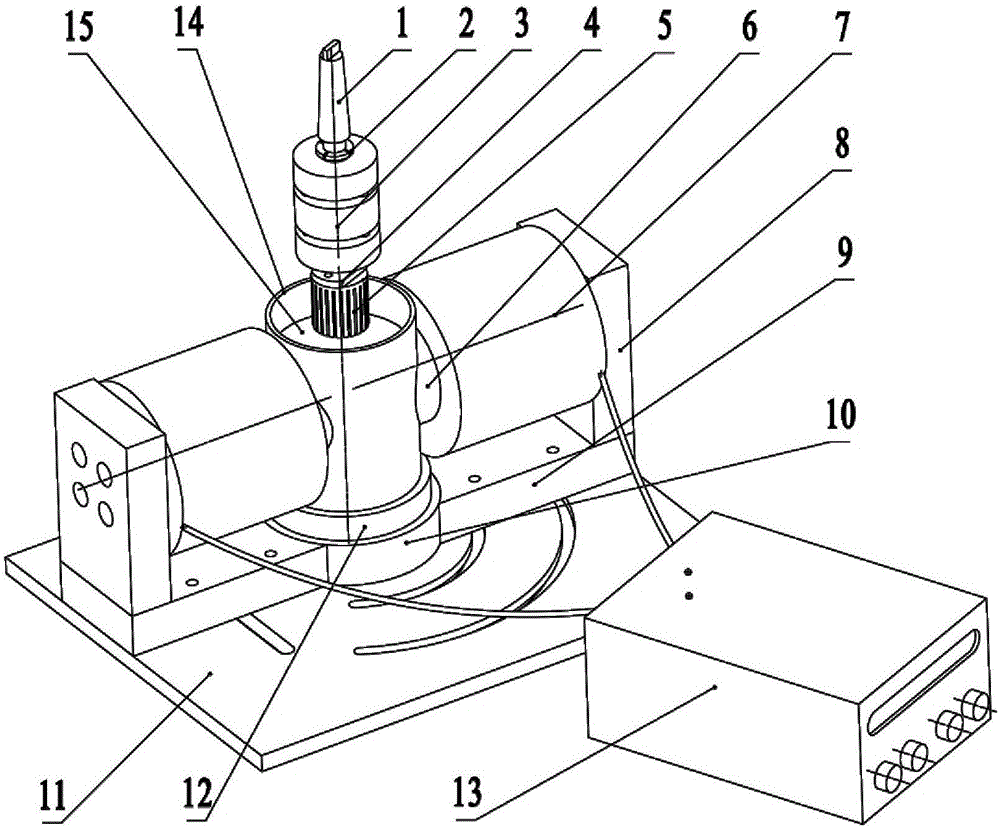

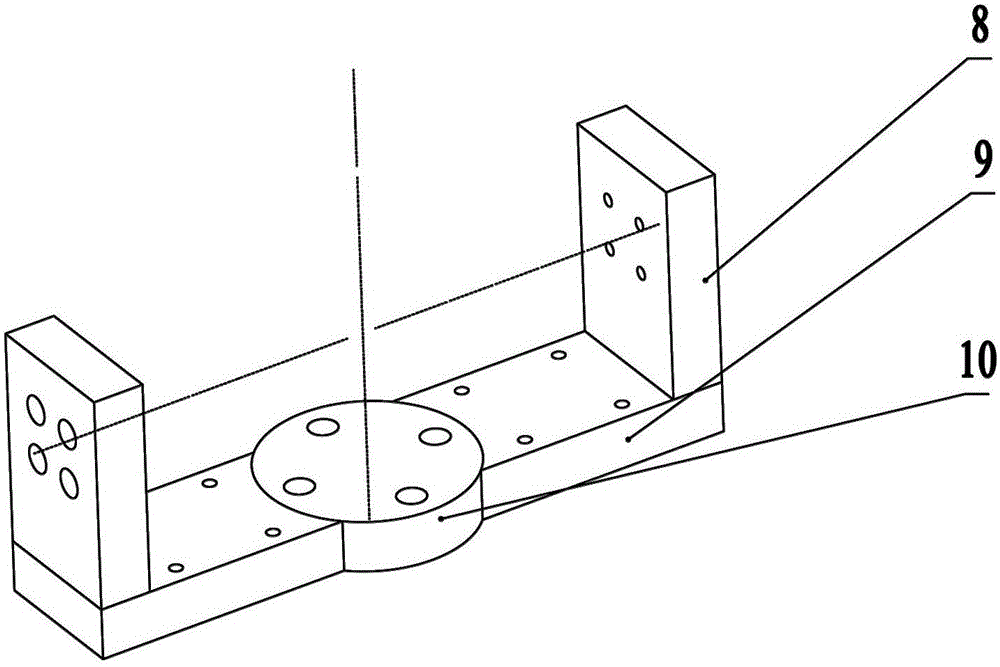

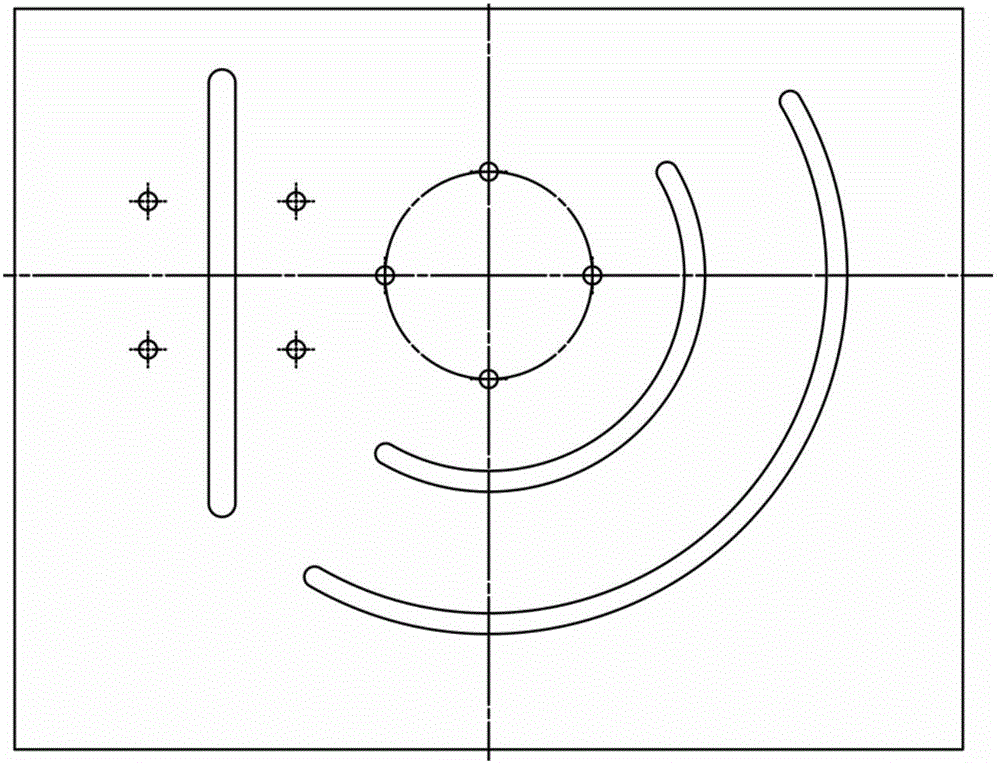

[0033] refer to Figure 1 to Figure 7, the high-voltage circuit breaker contact deburring device of the present embodiment is composed of a magnetic field generating device, a workpiece fixture, a magnetorheological processing fluid container, a driving device and a DC stabilized power supply, and the magnetic field generating device generates an external strengthening magnetic field, so that the magnetorheological The magnetorheological machining fluid in the machining fluid container undergoes phase transformation to form a flexible grinding layer in a Bingham-like solid state, and the driving device drives the circuit breaker contacts immersed in the magnetorheological machining fluid to rotate at high speed through the workpiece fixture to realize the opening edge of the contacts deburring process. Among them, the magnetic field generating device includes an electromagnet core 6, an electromagnetic coil 7, an iron yoke side plate 8, an iron yoke side bottom plate 9, an iro...

Embodiment 2

[0048] Such as Figure 6 As shown, the overall structure and implementation of the high-voltage circuit breaker contact deburring device are the same as in Example 1, the difference is that the magnetic pole angle of the magnetic field generator is adjusted to 150°, and other process parameters remain unchanged. The processing results of this example are: the edge rounding radius of the contact finger is 236 μm, the root rounding radius is 201 μm, and the surface roughness is 359.448 nm, which meets the requirements for removing burrs on the edge and root of the contact part.

Embodiment 3

[0050] Such as Figure 7 As shown, the overall structure and implementation of the high-voltage circuit breaker contact deburring device are the same as in Example 1, except that the magnetic pole angle of the magnetic field generating device is adjusted to 120°; other process parameters are adjusted as follows: The concentration is 20%, the spindle speed of the machine tool is 1000rpm, the current intensity of the DC stabilized power supply 13 is 3A, and the processing time is 20min. The processing results of this example are: the edge rounding radius of the contact finger is 313 μm, the root rounding radius is 285 μm, and the surface roughness is 289 nm, which meets the requirements for removing burrs on the edge and root of the contact part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com