Metal pipe section deburring device for electromechanical machining

A metal pipe, electromechanical technology, applied in the field of metal pipe deburring devices for electromechanical processing, can solve the problems of wasting time, health effects of workers, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

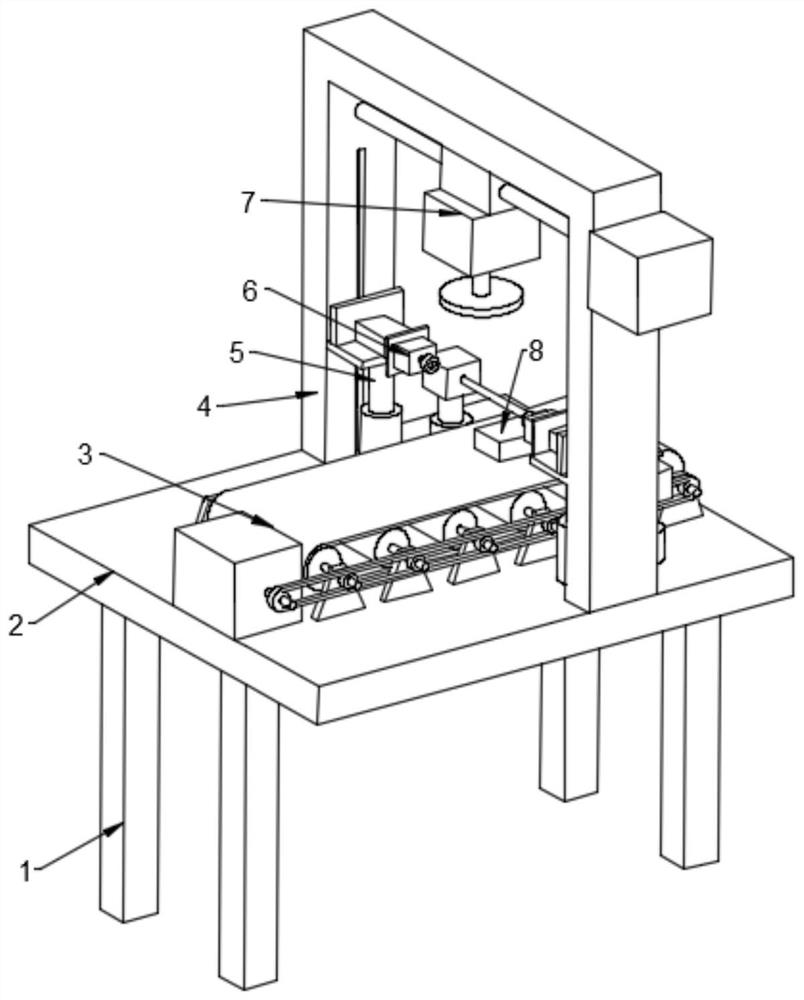

[0025] Such as figure 1 As shown, in one embodiment of the present invention, a metal pipe segment deburring device for electromechanical processing includes a support frame 1, a workbench 2 is arranged on the support frame 1, and a conveying device is arranged on the workbench 2 3. The workbench 2 is provided with a grinding frame 4 on both sides of the conveying device 3, the upper part of the grinding frame 4 is provided with a grinding device 7, and the lower part of the grinding frame 4 is provided with two lifting devices 5 distributed in mirror images. A clamping and rotating device 6 is provided on the lifting device 5 , and a blocking device 8 is provided on the upper side of the conveying device 3 .

[0026] In one embodiment of the present invention, when in use, the metal pipe can be directly placed on the conveying device 3, and the metal pipe is driven by the conveying device 3 to move, and when it reaches the position of the blocking device 8, it is blocked, and...

Embodiment 2

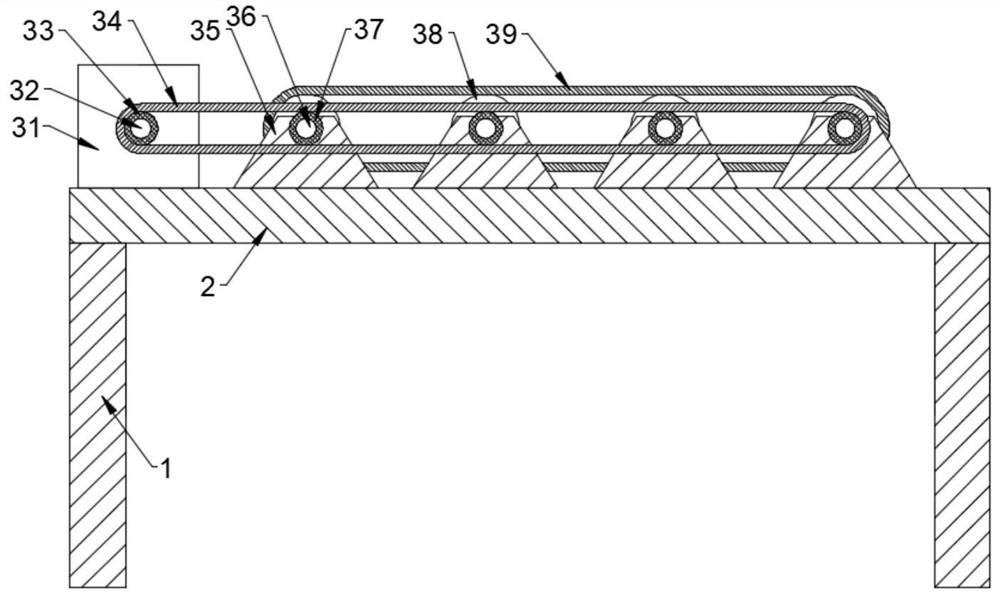

[0028] Such as figure 1 and 2 As shown, in another embodiment of the present invention, the conveying device 3 includes a first driving device 31, the first driving device 31 is arranged on the worktable 2, and the first driving device 31 passes through the driving shaft 32 Connected with a driving wheel 33, the driving wheel 33 cooperates with a plurality of groups of driven wheels 37 through a belt 34, and the inside of the driven wheel 37 is provided with a driven shaft 36, and the driven shaft 36 is rotatably connected to the support seat 35, so The bottom of the support seat 35 is fixed on the workbench 2, the driven shaft 36 is provided with a transmission roller 38, and the transmission roller 38 is equipped with a crawler belt 39; when the transmission device 3 is working, the first driving device 31 passes through the driving shaft 32 drives the driving wheel 33 to rotate, and the driving wheel 33 drives the driven wheel 37 to rotate through the belt 34, and the driv...

Embodiment 3

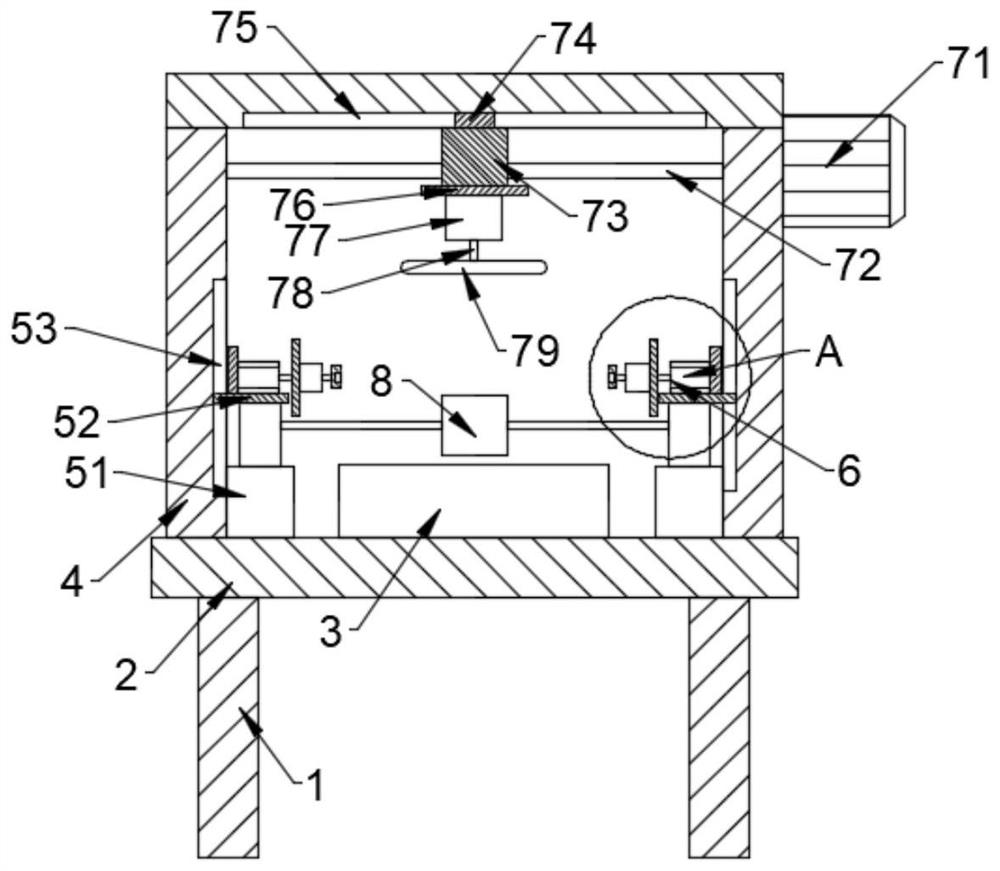

[0030] Such as image 3 and 4 As shown, in another embodiment of the present invention, the lifting device 5 includes a first telescopic rod 51, the bottom of the first telescopic rod 51 is fixed on the workbench 2, and the top of the first telescopic rod 51 is provided with Support plate 52, one end of the support plate 52 is slidingly fitted in the lifting groove 53, the lifting groove 53 is arranged on the side of the grinding frame 4, and the clamping and rotating device 6 is arranged on the supporting plate 52; 6 Clamp the metal pipe, and then the first telescopic rod 51 rises or falls to drive the support plate 52 to rise or fall along the interior of the lifting groove 53, thereby adjusting the height of the metal pipe. Since the support plate 52 is provided with a clamping device, the support plate 52 is used to 52 cooperates with the structure of the lifting groove 53 to ensure more stable clamping and more stable lifting.

[0031] In one embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com