Efficient polishing device of building plates

A technology for construction and plate materials, which is applied in the direction of machine tools, grinding machines, and grinding workpiece supports suitable for grinding workpiece planes. It can solve the problems of reducing production efficiency, low efficiency, and prolonging grinding time, and achieves the effect of all-round grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

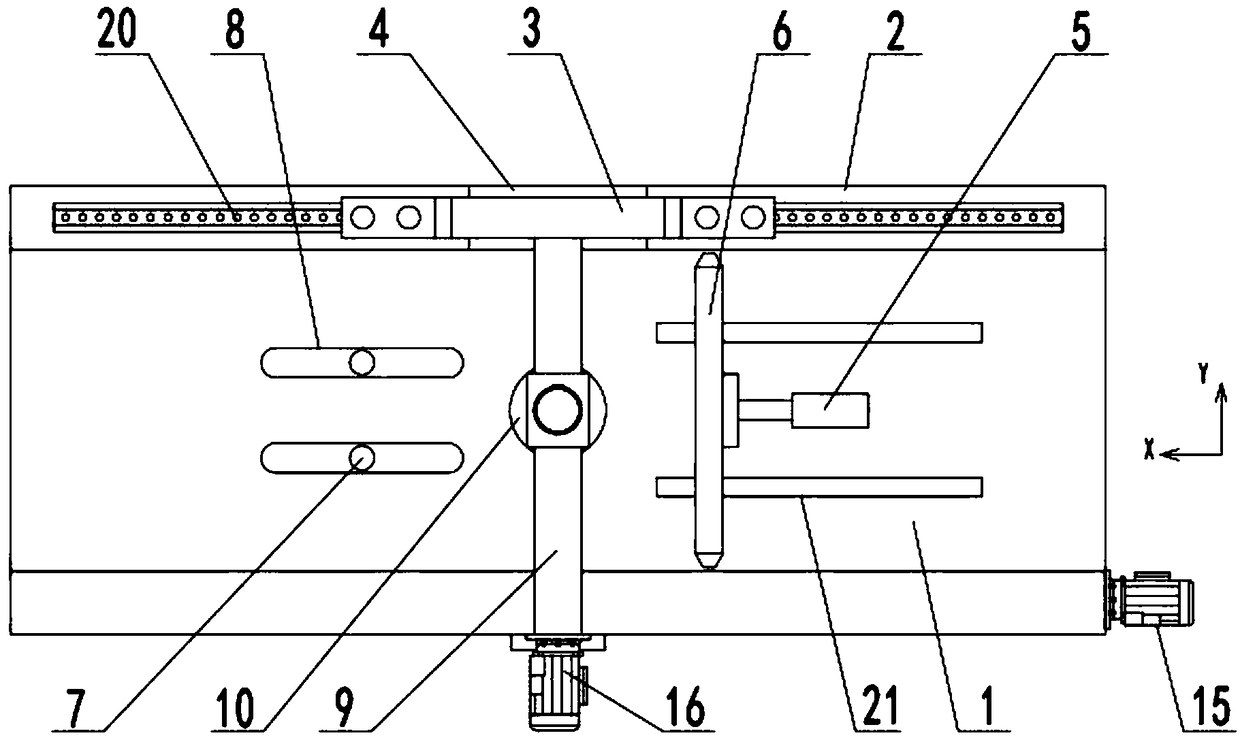

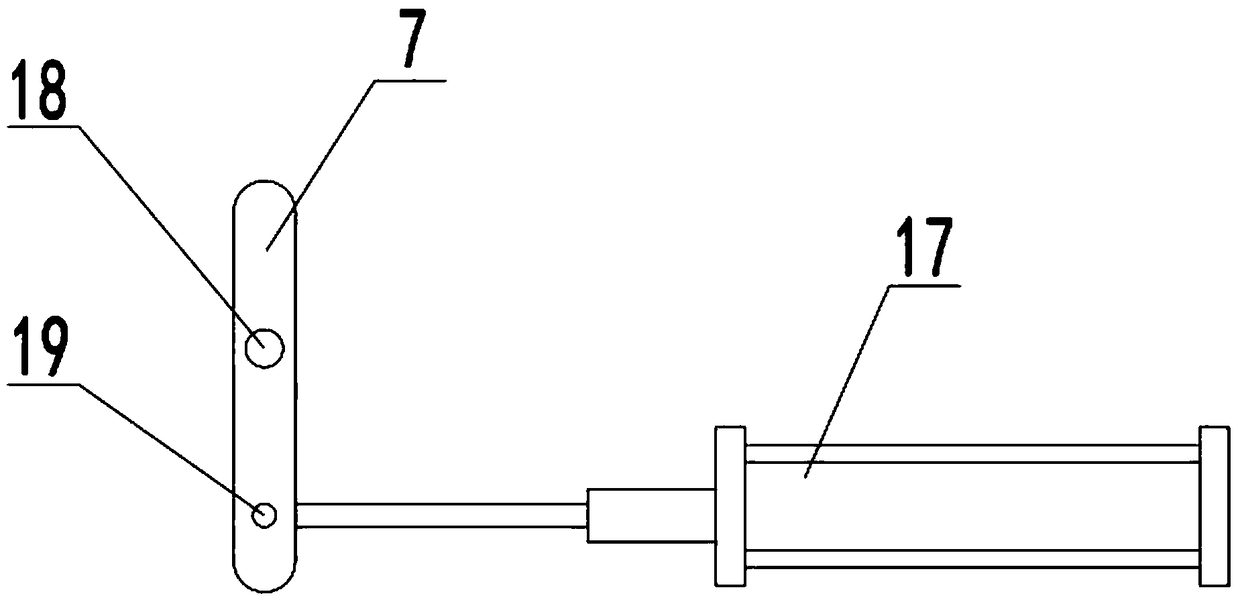

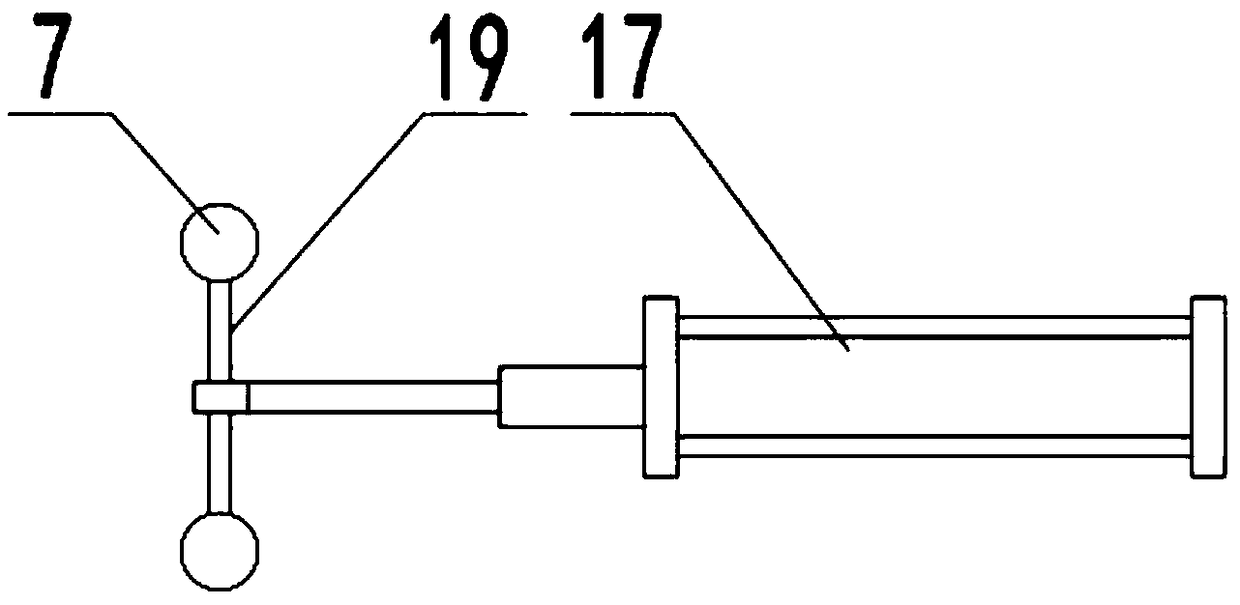

[0021] see Figure 1~3 , in an embodiment of the present invention, a high-efficiency grinding device for building boards includes a main body 1, a grinding device 10, and bases 2 fixed on both sides of the main body 1, so that the main body 1 is formed at a position between the corresponding two bases 2 A processing tank, wherein the base 2 on one side is provided with a feeding port 4, and the plate can be sent into the processing tank from the feeding port 4, and a pushing cylinder 5 is installed in the processing tank, and the output of the pushing cylinder 5 A pusher plate 6 is installed at the end, and the pusher plate 6 cooperates with the retaining shaft 7 to realize the positioning of the plate. The grinding device 10 is installed on the beam 9, and the beam 10 is directly above the body 1. The grinding device 10 The plate in the processing tank can be polished, the body 1 is provided with several waist-shaped relief grooves 8, and the middle position of each of the r...

Embodiment 2

[0024] see figure 1 and 4 , in the embodiment of the present invention, one end of the crossbeam 9 is fixed on the bracket 3, the bracket 3 is a U-shaped structure with a space for the feed port 4, the bracket 3 is installed on the base 2, and the other end of the crossbeam 9 passes through The movable support base 13 is installed on the base 2 to form a support for the grinding device 10 .

[0025] Of course, in order to facilitate the movement of the grinding device 10, so that the grinding device 10 can grind the plate in all directions, one of the bases 2 is provided with a mounting groove 10, and an X-direction screw assembly 12 is installed in the mounting groove 10. The X-direction screw assembly 12 is driven by the X-direction servo motor 15, and the movable support seat 13 is fixedly connected with the screw nut in the X-direction screw assembly 12. Similarly, the base 2 where the bracket 3 is located is provided with a 3. When the guide rail 20 is slidingly fitted,...

Embodiment 3

[0028] On the basis of Embodiments 1 and 2, a high-efficiency grinding device for building boards also includes a dust suction device installed on the body 1. Specifically, the structure of the dust suction device belongs to the prior art, and no redundant details are made here. narrative.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com