All-directional grinding device for cylindrical electronic components

An electronic component, all-round technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problem that the grinding device cannot perform continuous grinding, cannot achieve all-round, and reduce the grinding quality, etc. Achieve the effect of improving air treatment quality, avoiding clogging and improving grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

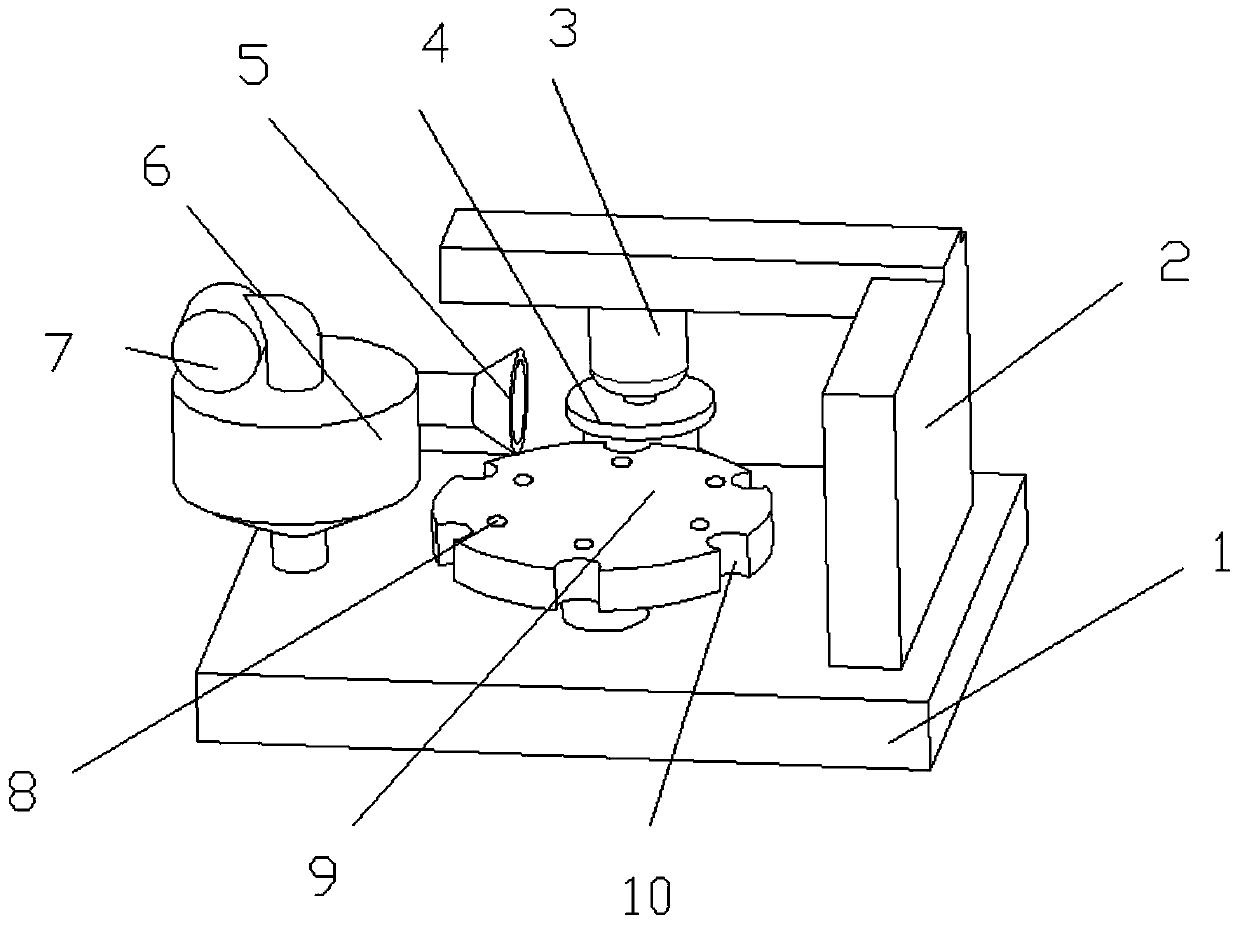

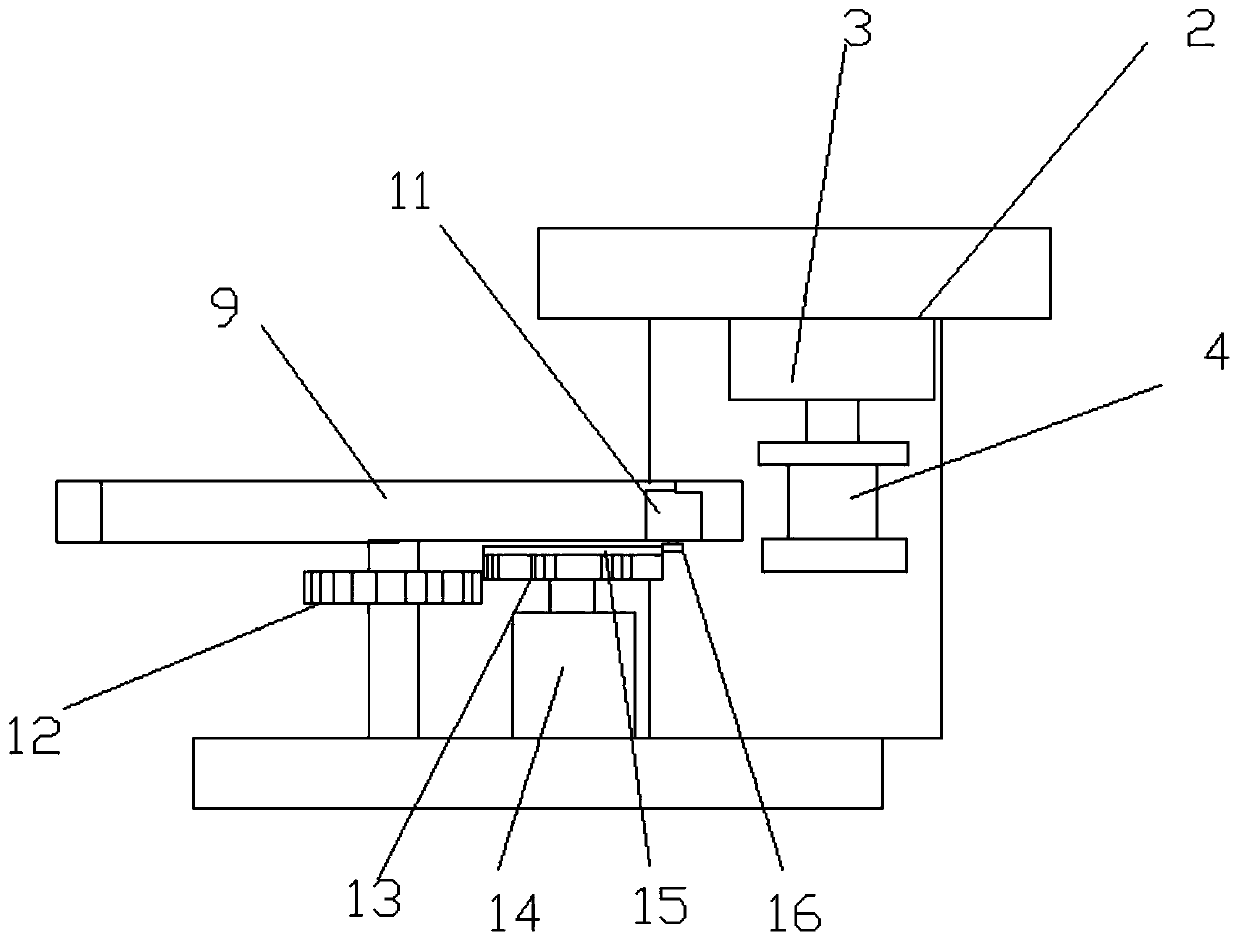

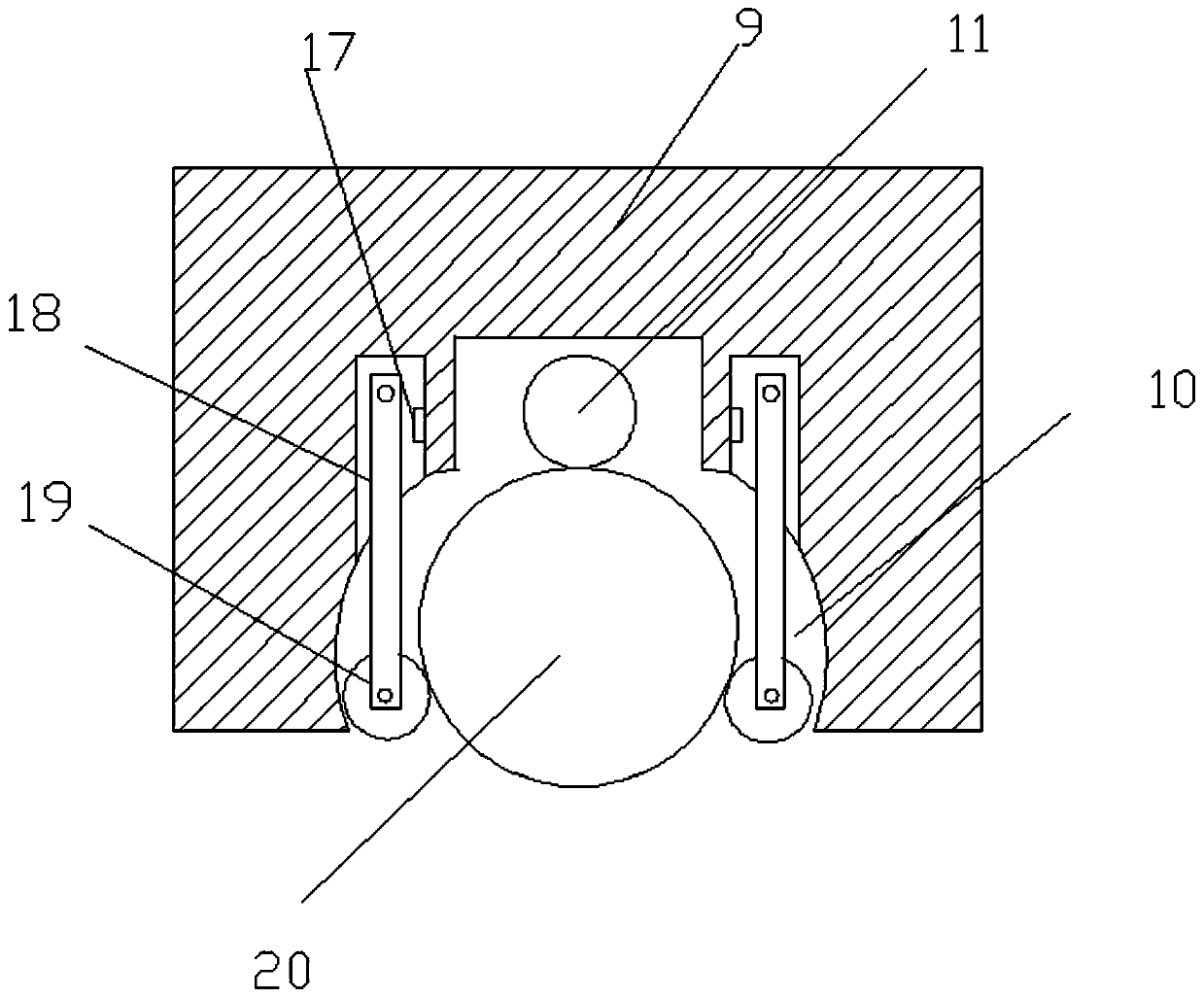

[0023] see Figure 1-4 , an all-round grinding device for cylindrical electronic components, including a workbench 1, a cyclone separator 6 and a rotating fastening disc 9. The upper surface of the workbench 1 is equipped with a cyclone separator 6 and a rotating fastening disk 9, and the side of the rotating fastening disk 9 is fixedly equipped with a support frame 2 on the upper surface of the workbench 1, and the support frame 2 is an L-shaped structure. A first motor 3 is fixedly installed on the top lower surface of the support frame 2 , and the output shaft of the first motor 3 coaxially fixes a grinding wheel 4 , driven by the first motor 3 , the grinding wheel 4 rotates to grind the electronic components 20 . The rotating fastening disc 9 is arranged on the upper surface of the workbench 1, and the bottom of the rotating fastening disc 9 is coaxially fixedly connected with a gear 12, and the side of the gear 12 is fixedly installed with a second motor 14 on the workben...

Embodiment 2

[0028] On the basis of Embodiment 1, the middle position of the dust filter screen 23 is fixedly provided with a central shaft 25, on which a brush 24 and fan blades 26 are coaxially rotated, and the brushes 24 and fan blades 26 are fixedly connected. Hairbrush 24 contacts with dust filter screen 23 bottoms, and the air of flow drives fan blade 26 to rotate, thereby hairbrush 24 is rotated, and the dust on the 24 dust filter screens 23 of rotating brushes is cleaned up. The clogging of dust filter screen 23 is avoided, and the filtering of guarantee is carried out smoothly. The grinding wheel 4 is a dumbbell-shaped structure with thin middle and thick ends, and the setting of the grinding wheel 4 is convenient for grinding the side and both ends of the electronic component 20, so that the grinding is more sufficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com