Grinding machine for inner wall of automobile air conditioner compressor cylinder body

A technology for compressor cylinders and automotive air conditioners, which is applied in the direction of grinding machines, grinding workpiece supports, grinding drive devices, etc., and can solve the problems of affecting the grinding efficiency of cylinders, poor grinding effect, and difficulty in all-round grinding of cylinders, etc. , to achieve the effect of reducing labor costs, ensuring the consistency of grinding, and ensuring the quality of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

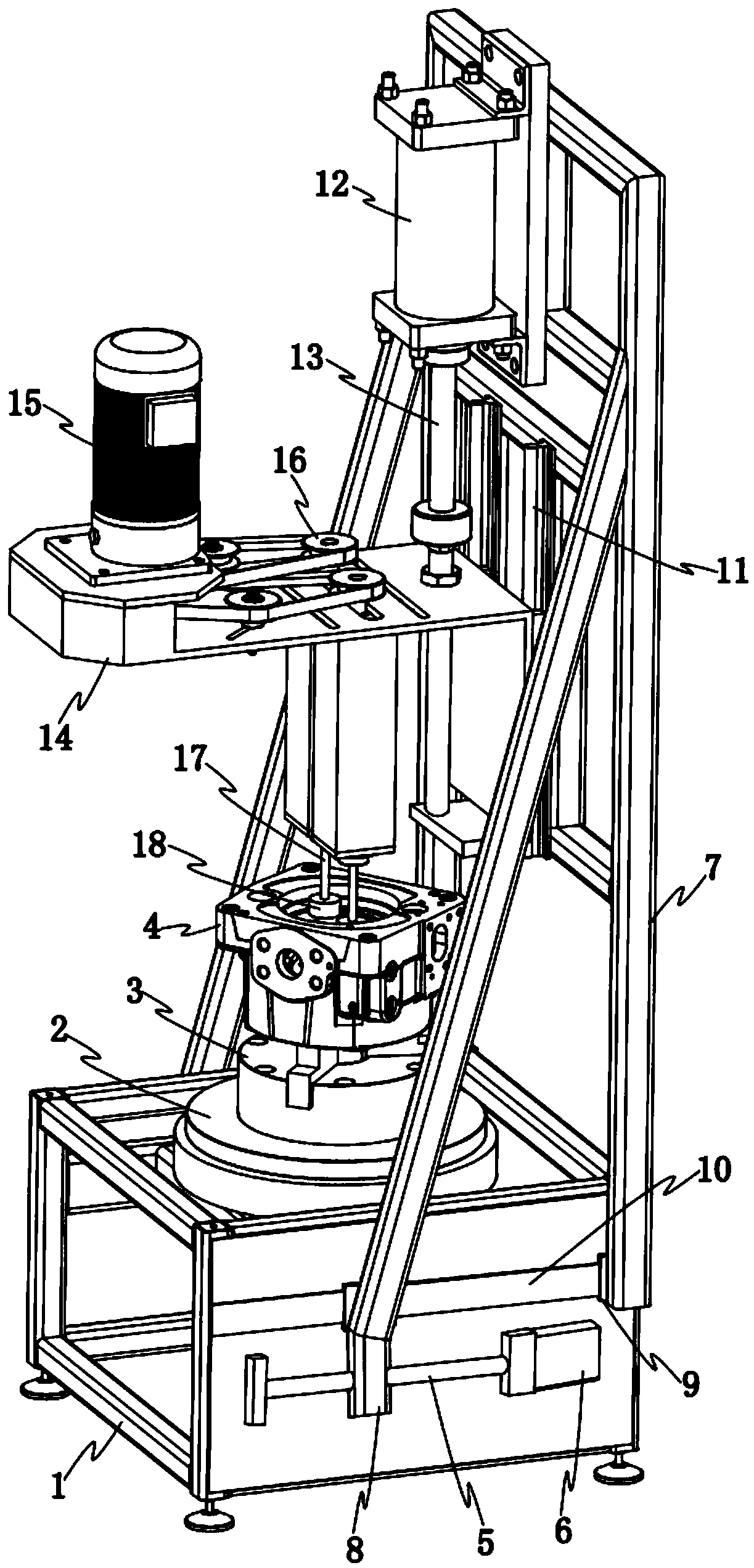

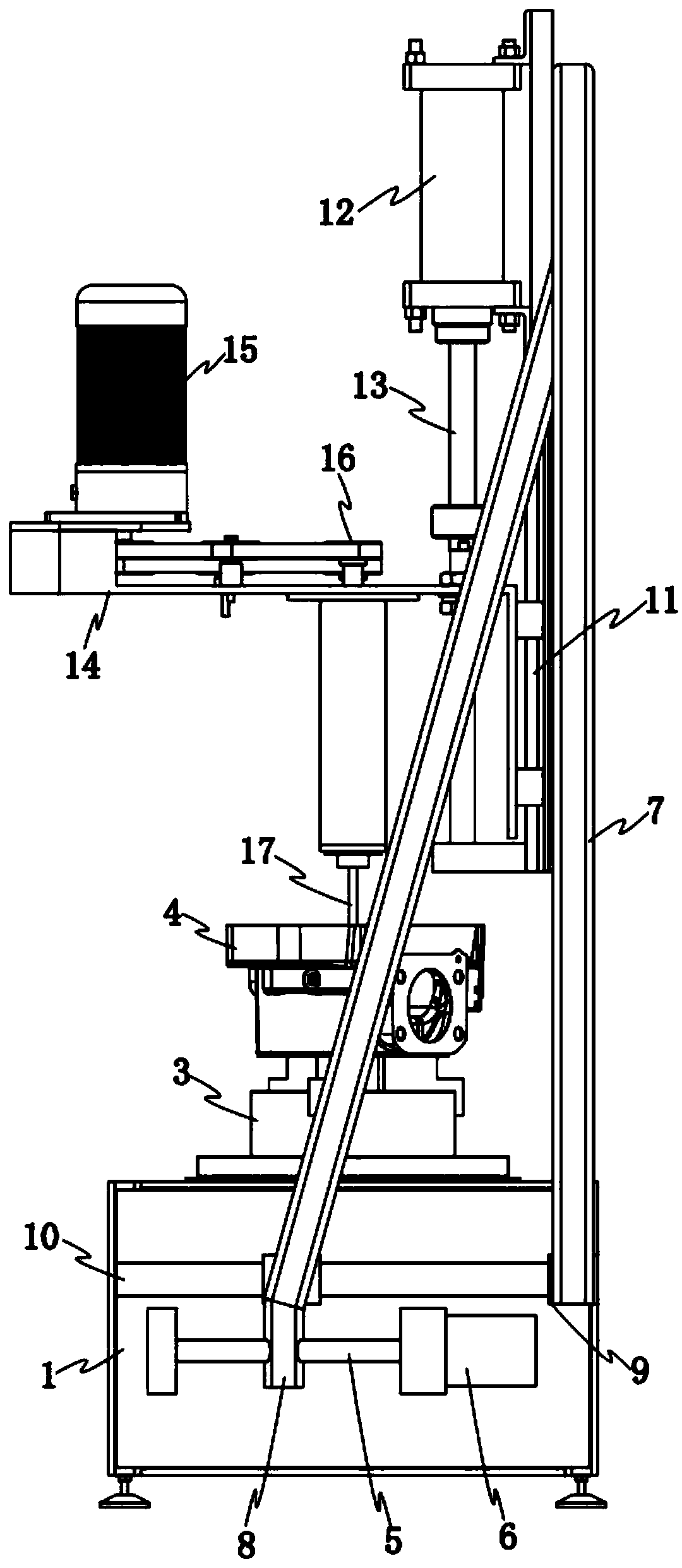

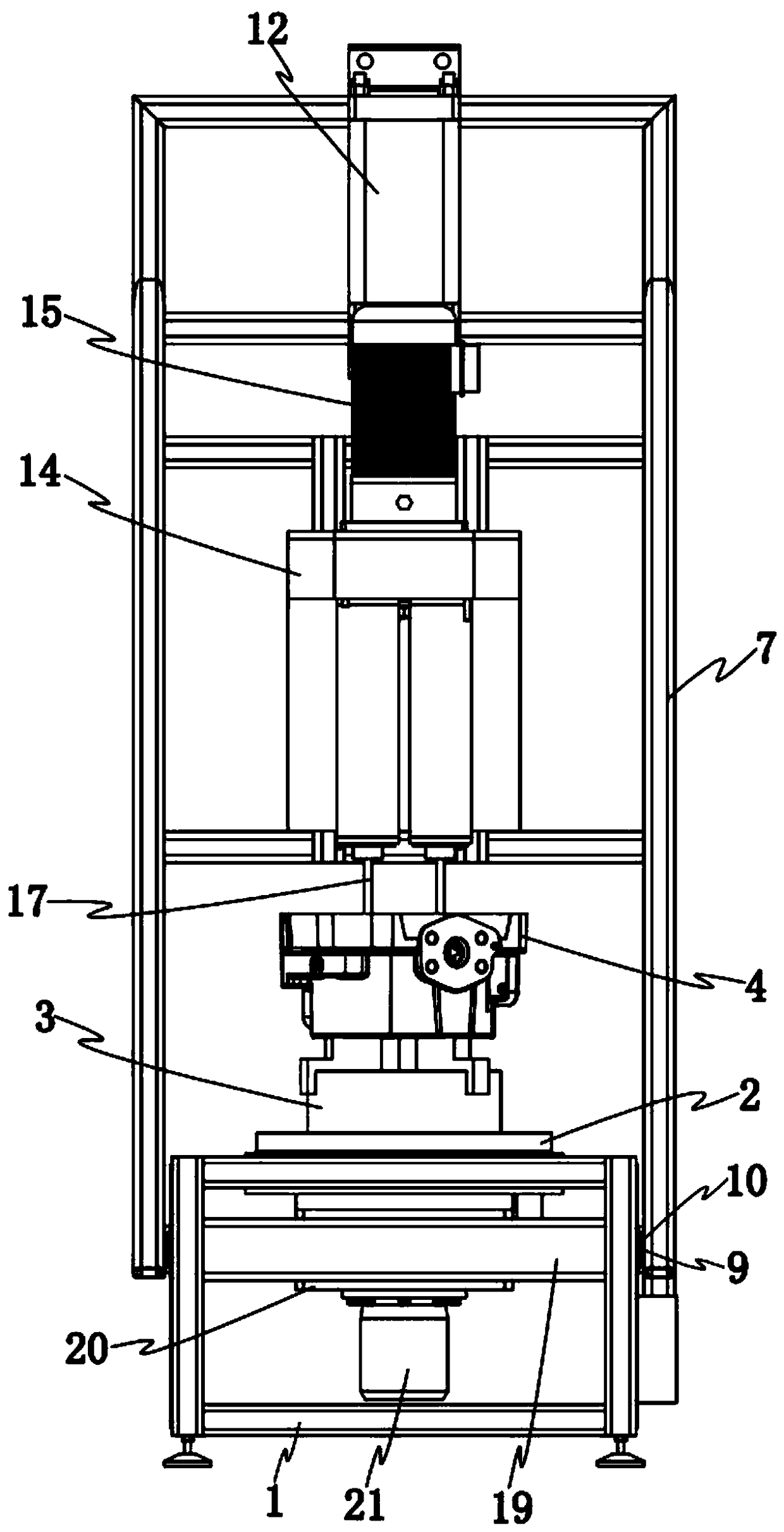

Embodiment 1

[0024] When the grinding machine grinds the inner wall of the compressor cylinder 4, the compressor cylinder 4 is manually clamped on the workpiece holder 3, and then the grinding drive motor 15 on the displacement plate seat 14 is started, and the grinding drive motor 15 passes through The belt drive drives the grinding wheel 18 on the vertical shaft 17 to rotate, and simultaneously starts the rotary drive motor 21 at the bottom of the slide seat 20, and the rotary drive motor 21 drives the rotation of the workpiece holder 3 and the clamped compressor cylinder 4 to rotate the compressor. The inner wall of the cylinder body 4 is polished, and the displacement drive motor I12 on the tripod body 7 drives the displacement plate base 14 to move down along the vertical slide rail 11, and drives the vertical rotating shaft 17 connected with the displacement plate base 14 and the shaft lower end. The grinding wheel 18 moves down into the compressor cylinder 4, and at the same time sta...

Embodiment 2

[0026] During the process of grinding the inner wall of the compressor cylinder 4 by the grinding wheel 18, the displacement drive motor II 23 drives the workpiece holder 3 and the compressor cylinder 4 on it to slide along the parallel slide bar 19 to realize the left and right positions of the compressor cylinder 4. adjustment, and the tripod body 7 is driven to slide along the horizontal slide rail 10 by the displacement drive motor III6 to realize the front and rear position adjustment of the rotating grinding wheel 18, and the displacement plate seat 14 is driven by the displacement drive motor I12 on the tripod body 7 Slide along the vertical slide rail 11 to realize the adjustment of the up and down position of the rotating grinding wheel 18, thereby adjusting the left and right positions of the compressor cylinder 4 and cooperating with the adjustment of the front and rear positions and up and down positions of the grinding wheel 18 to realize the adjustment of the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com