Pipeline polishing equipment for outdoor buildings

A technology for construction and pipelines, which is applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc. It can solve the problems of ungrinding, heavy operation of workers, and rusting of pipelines, so as to improve the quality of grinding, reduce manual operations, The effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

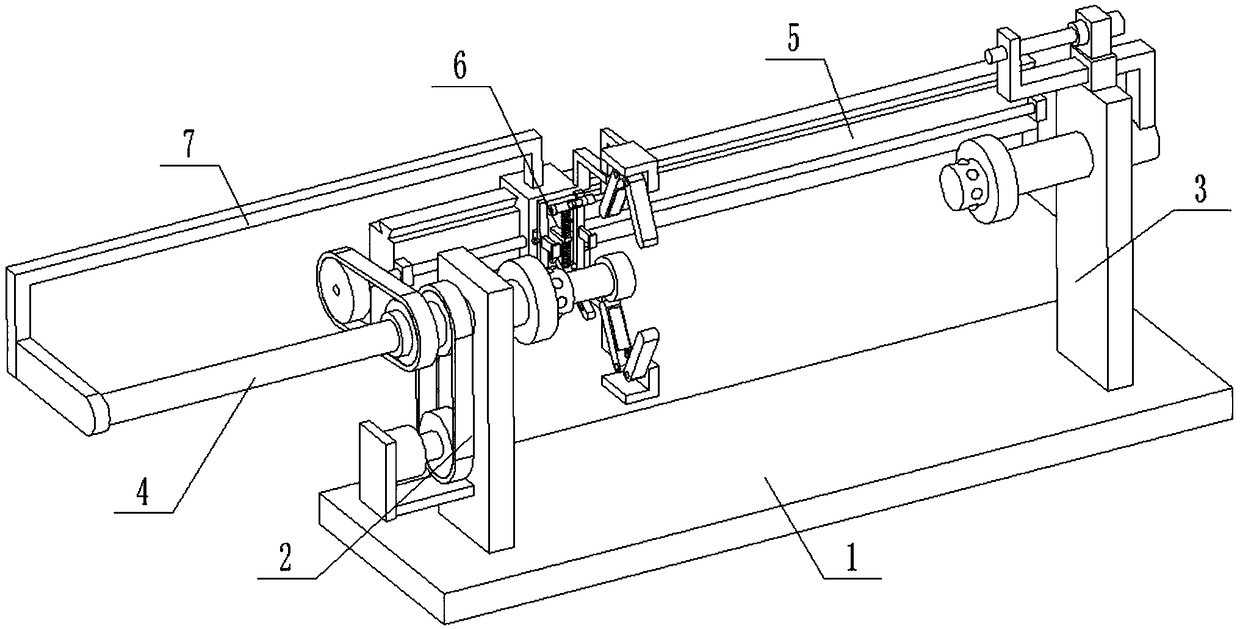

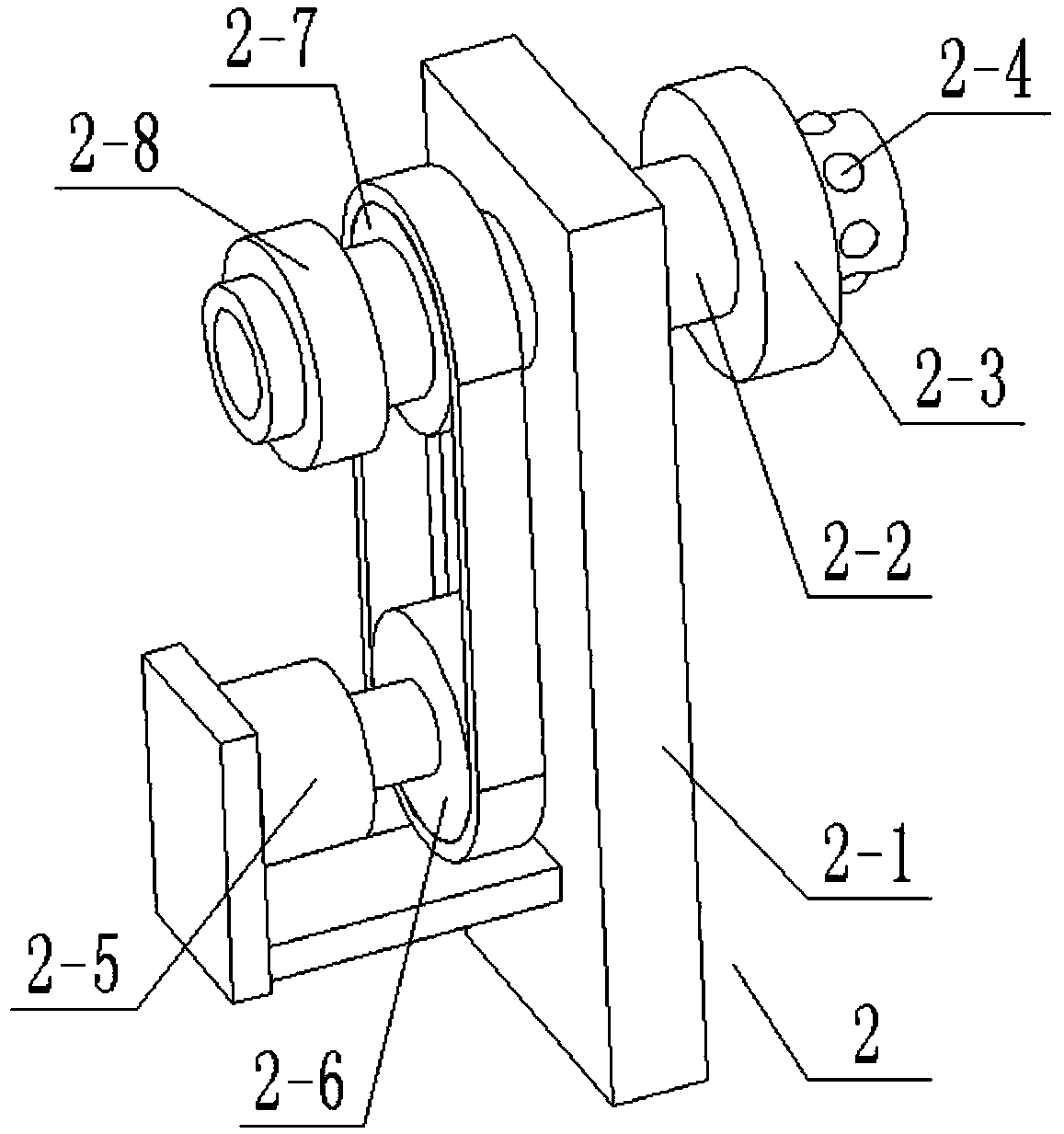

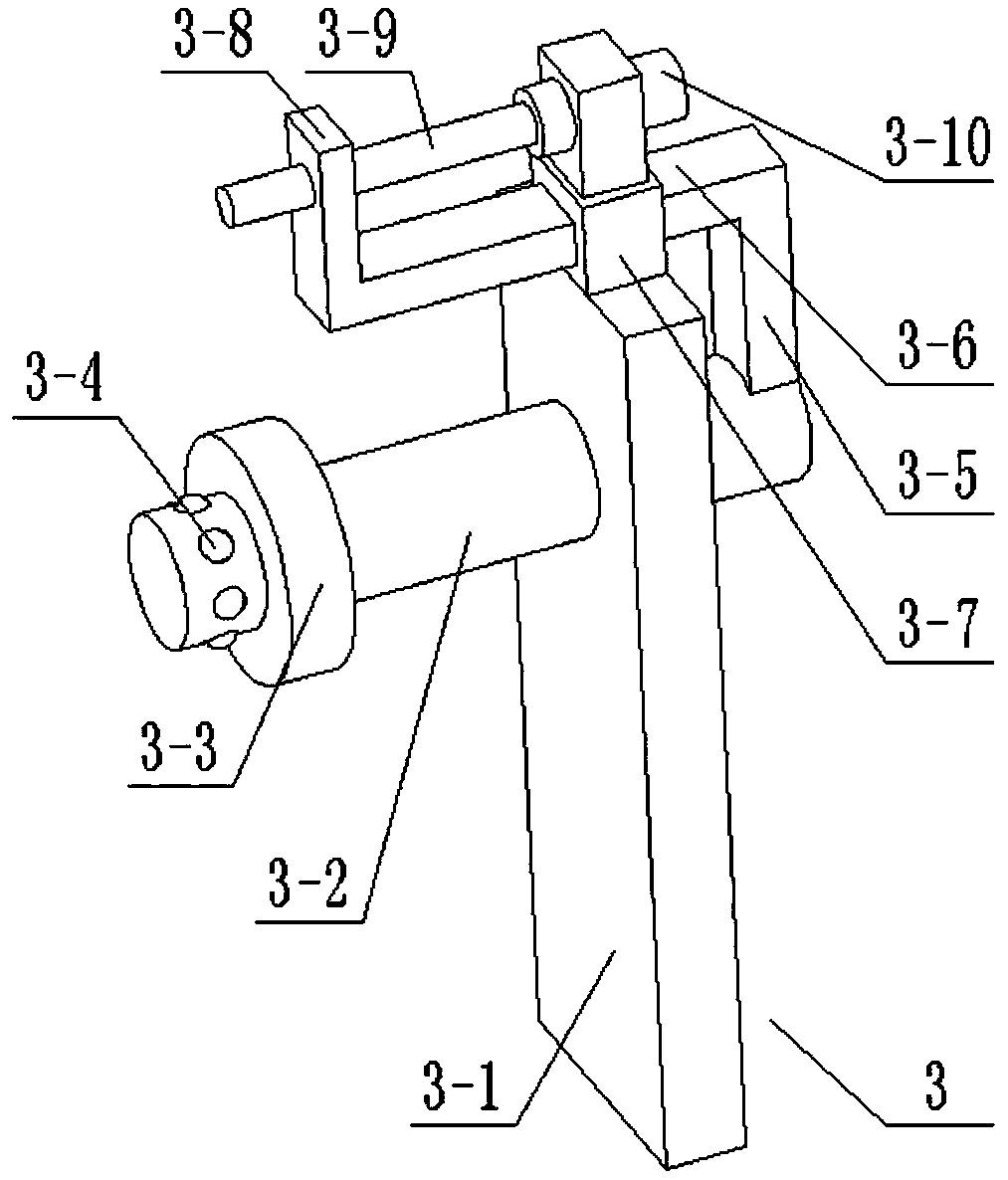

[0028] Combine below Figure 1-10 Describe this embodiment, a pipe grinding equipment for outdoor construction, including a bottom plate 1, a left pipe support 2, a right pipe support 3, an inner surface grinding part 4, a slide rail seat 5, an outer surface grinding part 6 and a connecting arm 7 , the left pipe support 2 includes a left support plate 2-1, a shaft sleeve 2-2, a left top seat 2-3, a rubber protrusion I2-4, a motor I2-5, a driving pulley 2-6, and a The driving pulley 2-7 and the driving pulley 2-8; the left support plate 2-1 is fixedly connected to one end of the base plate 1, and the middle end of the axle sleeve 2-2 is connected to the left support plate 2-1 through a bearing with a seat for rotation , the left top seat 2-3 and the driving pulley 2-8 are respectively fixedly connected to the two ends of the shaft sleeve 2-2, and a plurality of rubber protrusions I2-4 are evenly arranged on the shaft sleeve 2-2, and a plurality of rubber protrusions I 2-4 are ...

specific Embodiment approach 2

[0033] Combine below Figure 1-10 To illustrate this embodiment, the axes of the telescopic shaft rod 3-2, the bushing 2-2, the smooth rod 4-1 and the grinding disc 4-2 are all coincident, so that the inner wall of the pipe after grinding is not deviated from the axis of the outer wall.

specific Embodiment approach 3

[0034] Combine below Figure 1-10 To illustrate this embodiment, the sliding frame 6-8 includes a left panel 6-8-1, a right panel 6-8-2 and a side bar 6-8-3; the left panel 6-8-1 and the right panel 6- Two side bars 6-8-3 are fixedly connected between 8-2, and fastening screws 6-9 are threaded on the left side plate 6-8-1; left side plate 6-8-1 and right side plate 6-8 -2 are respectively slidably connected to the two guide rods 6-7, and the two hinged rods 6-3 are all located on the left side plate 6-8-1, the right side plate 6-8-2 and two side bars 6-8-3 to form In the rectangular space, the outer surfaces of the two hinged rods 6-3 lean against the two side rods 6-8-3 respectively. When the slide frame 6-8 is in use, the left panel 6-8-1 and the right panel 6-8-2 can move back and forth on the two guide rods 6-7, and the left panel 6-8-1 and the right panel When 6-8-2 moves forward, the two side bars 6-8-3 will squeeze the two hinged bars 6-3, and tighten the fastening sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com