Integrated rust removing and preventing equipment for steel manufacturing

A technology for steel and equipment, applied in the field of steel manufacturing, can solve problems such as affecting manufacturing efficiency, destroying steel performance and manufacturing process, and being easy to miss, so as to ensure the effect of rust removal and improve grinding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

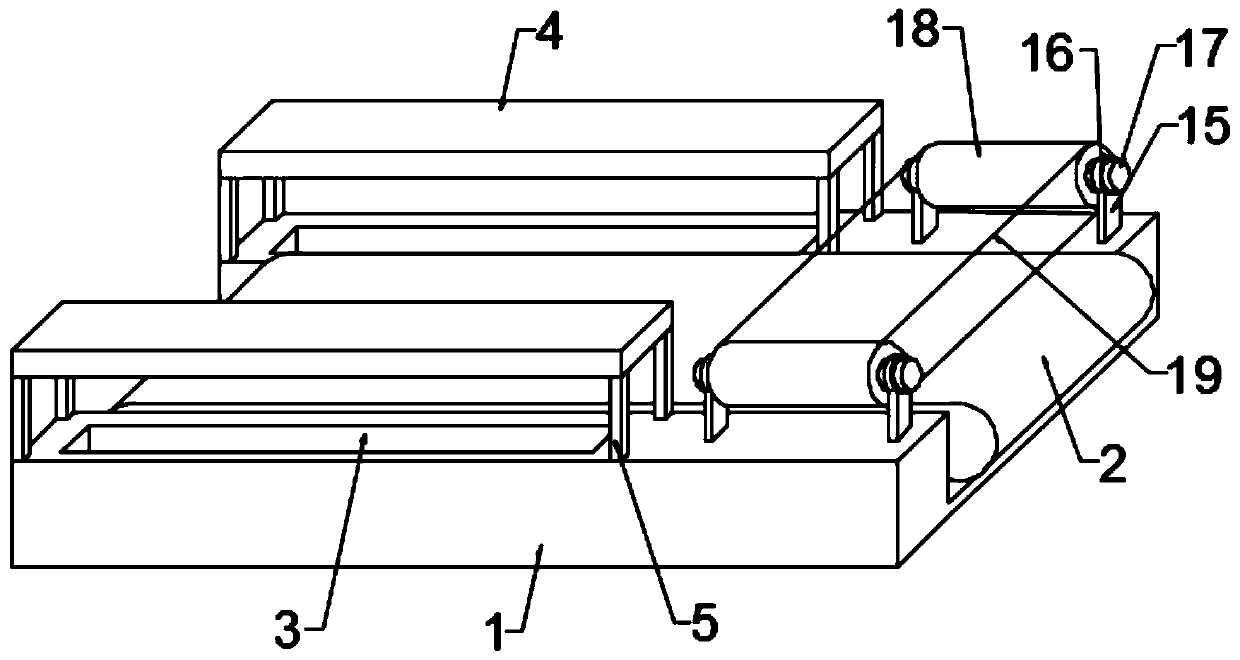

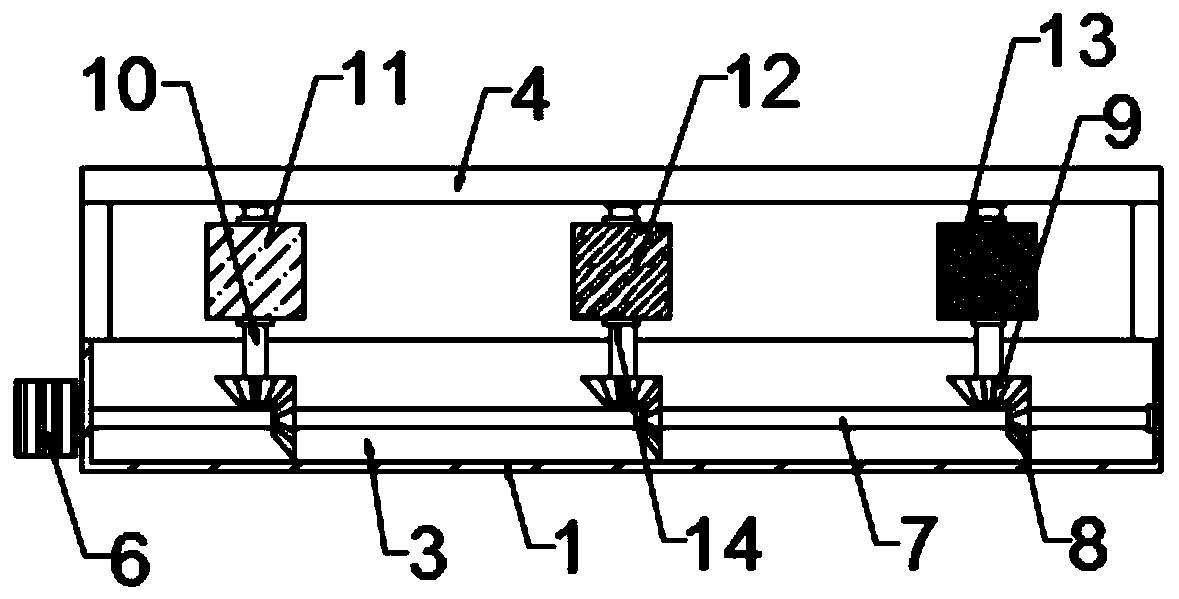

[0034] see figure 1 , in one embodiment provided by the present invention, an integrated rust removal and antirust equipment for steel manufacturing, including a concave worktable 1 and a transport platform 2, the transport platform 2 is located in the concave groove of the concave worktable 1 Middle; the front end of the concave workbench 1 is provided with a multi-stage grinding and derusting mechanism, and the multi-stage grinding and derusting mechanism is symmetrically installed on both sides of the transport table 2; the rear of the concave workbench 1 An anti-rust mechanism is provided at the end, and the anti-rust mechanism spans above the transport platform 2; a mounting plate 22 is placed on the upper surface of the transport platform 2, and a steel material 23 is rotatably mounted on the mounting plate 22.

[0035] The rust removal and anti-rust integrated equipment for steel manufacturing realizes automatic grinding and rust removal without manual grinding, which i...

Embodiment 2

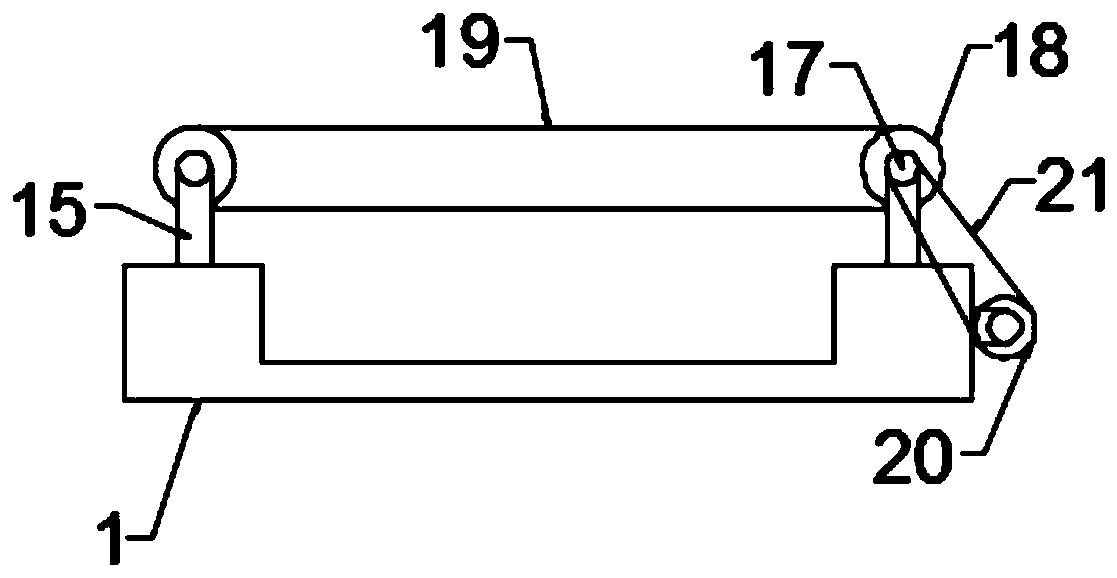

[0044] see Figure 4~5 , in another embodiment provided by the present invention, one side of the mounting plate 22 is fixed with an L-shaped support plate 24, the other end of the mounting plate 22 is equipped with a rotating mechanism, and one end of the steel 23 passes through the fixing assembly and The rotating mechanism is fixedly connected, and the other end of the steel material 23 is rotatably connected to the L-shaped support plate 24 through another fixed component.

[0045] Further, the rotating mechanism includes a second motor 26 installed on the upper surface of the mounting plate 22, the output shaft of the second motor 26 is sleeved with a driving wheel 27, and the driving wheel 27 is driven by a belt 29. The driving wheel 28 is in transmission connection, and the driven wheel 28 is connected with the fixed assembly.

[0046] Start the second motor 26, the second motor 26 drives the driven wheel 28 to rotate by driving the driving wheel 27 to rotate, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com