Intelligent full-automatic spraying equipment

A spraying equipment, fully automatic technology, applied in the direction of metal processing equipment, grinding/polishing equipment, spray booths, etc., can solve the problems of inability to polish, dust remove and paint the workpiece, low efficiency, general quality and effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

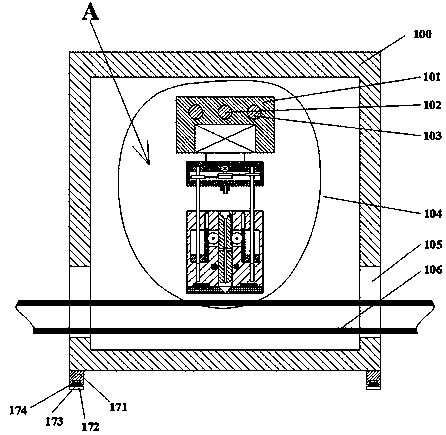

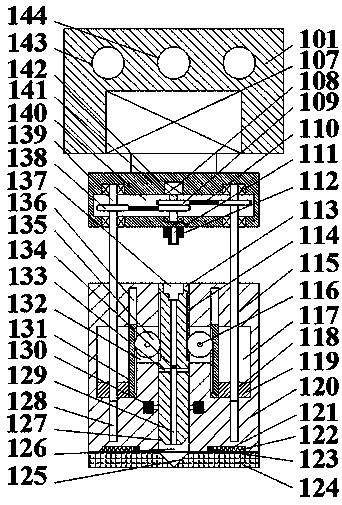

[0016] like Figure 1-Figure 2 As shown, an intelligent automatic spraying equipment of the present invention includes a body 100 and a first sliding cavity 104 arranged in the body 100, and the first sliding cavity 104 can be slid back and forth through a sliding component. There is a sliding frame 101, a first motor 107 is fixed in the sliding frame 101, the driving shaft of the first motor 107 extends downward, and a turret 141 is fixedly installed at the bottom end, and a first motor 141 is arranged in the turret 141 Cavity 140, a first rotating shaft 142 extending up and down is rotatably disposed in the first cavity 140, and the bottom end of the first rotating shaft 142 is rotatably disposed in the bottom wall of the first cavity 140. The top end of a rotating shaft 142 is powered with the second motor 108 fixedly arranged in the top wall of the first cavity 140. The outer surface of the first rotating shaft 142 is fixedly installed with a first pulley 109 that is symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com