Medical planing grinding head

A grinding and planing technology, which is applied in the fields of medical science and surgery, can solve the problems of reduced surgical efficiency, unstable field of vision in the surgical area, overflow of lavage fluid, etc., to improve surgical efficiency, increase surgical safety, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

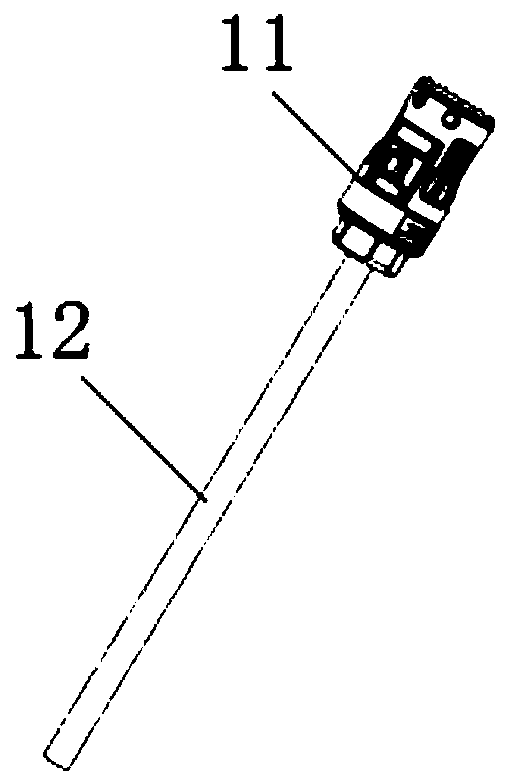

[0025] Step 1: After checking the joint with arthroscopy, extend the outer knife into the lesion to be removed.

[0026] Step 2: Put the inner knife into the outer knife to ensure that the head of the inner knife can be fully exposed (such as Figure 5 ), and grind away the joint lesion.

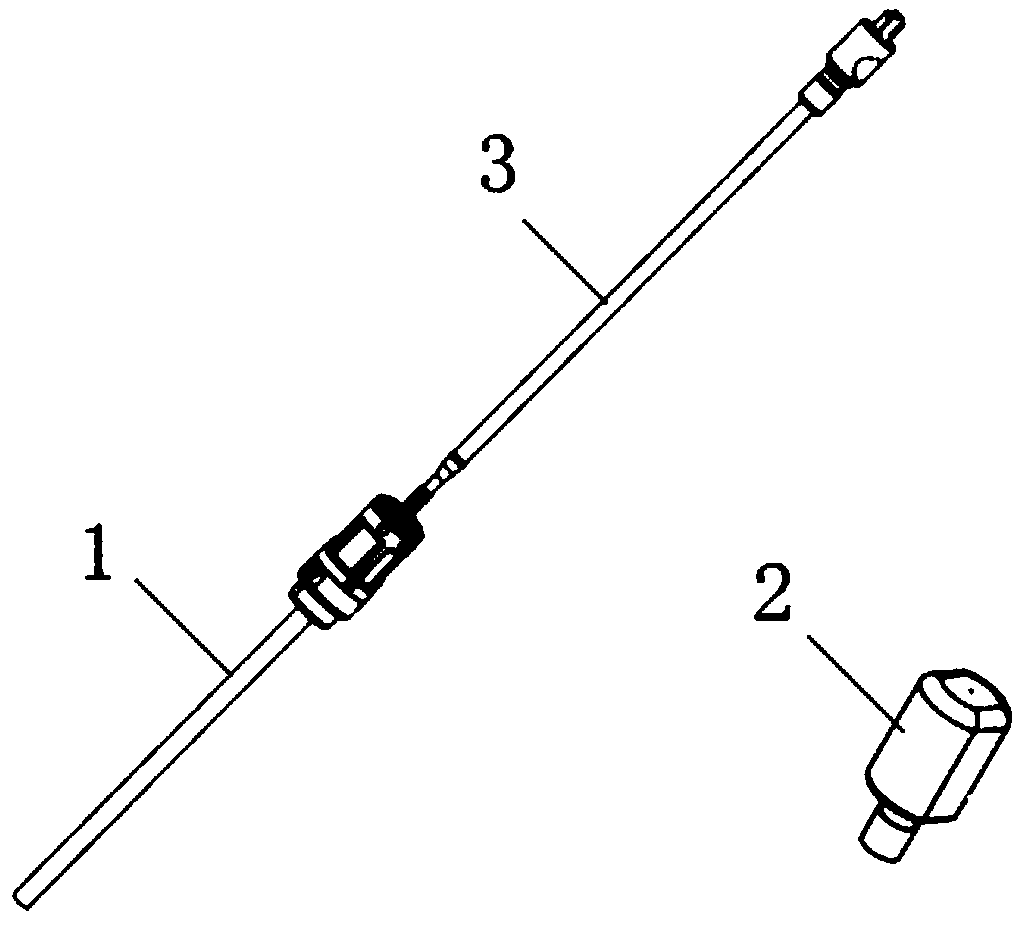

[0027] Step 3: Pull out the used inner knife from the outer knife (such as figure 1 ).

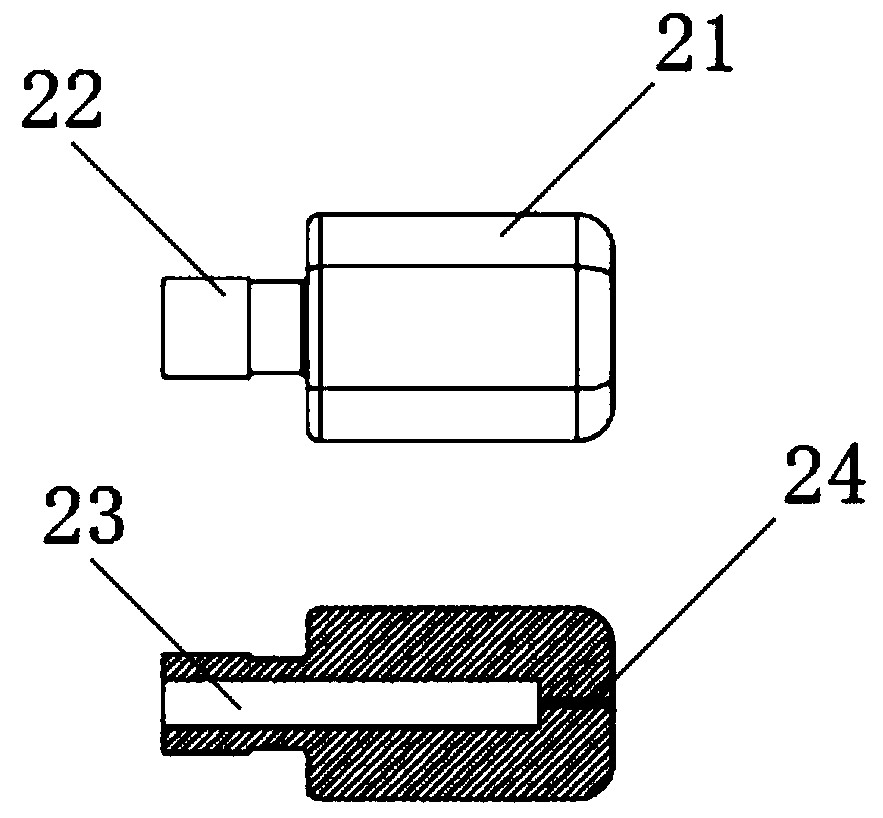

[0028] Step 4: Use the plug 2 to block the mouth of the outer knife tube to prevent the irrigation fluid from overflowing (such as Image 6 ).

[0029] Step 5: Take off the plug 2, and put the replacement inner knife into the outer knife tube 12.

[0030] Compared with the existing technology, after the plug is designed for the planing cutter head, it can replace the inner knife to block the outer knife tube when replacing the inner knife during the operation, so as to ensure that the lavage fluid will not overflow from the outer knife tube, and at the same time The air in the operation area can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com