Surface grinding and rust-removing device for distance-adjustable type air duct motor rotary shaft

A technology of motor shaft and shape adjustment, which is applied in the direction of grinding drive device, grinding machine, grinding workpiece support, etc., can solve the problems of low grinding efficiency and rust on the surface of the rotating shaft, so as to improve the effect, improve work efficiency, and protect ears. effect of hearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

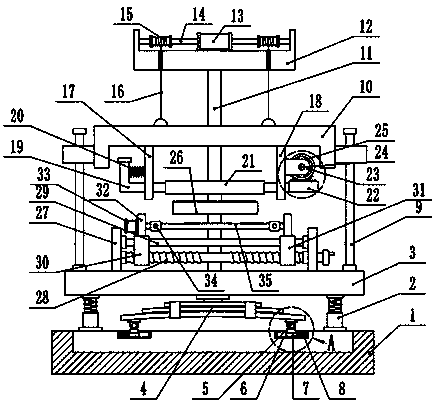

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

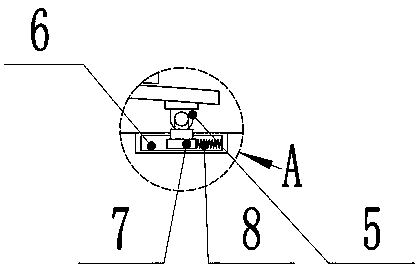

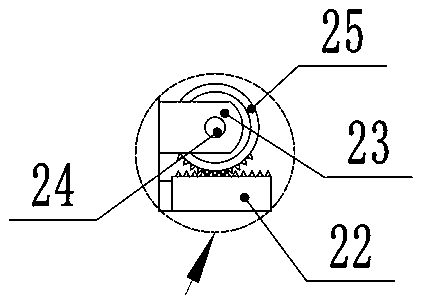

[0023] see Figure 1-4 , a distance-adjustable air duct motor shaft surface grinding and derusting device, including a base 1, a support table 3, a biaxial motor 13, a first drive motor 24, a derusting head 26 and a second drive motor 33, the base The two sides of the upper surface of 1 are provided with shock-absorbing columns 2, and shock-absorbing springs are installed on the shock-absorbing columns 2. The upper side of the shock-absorbing columns 2 is provided with a supporting platform 3, and the lower center of the supporting platform 3 is fixedly installed with a Shock-absorbing spring sheet 4, the left and right parts of the lower side of the shock-absorbing spring sheet 4 are welded with connectors 5, the lower side of the connector 5 is welded with a slider 7, the surface of the base 1 is provided with a chute 6, and the slider 7 is slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com