Pipe grinding device for building construction

A construction and pipeline technology, applied in grinding machines, manufacturing tools, grinding skateboards, etc., can solve the problems of unpolished, rusted pipes, and high labor intensity of workers, so as to improve grinding quality, reduce work intensity, and improve grinding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

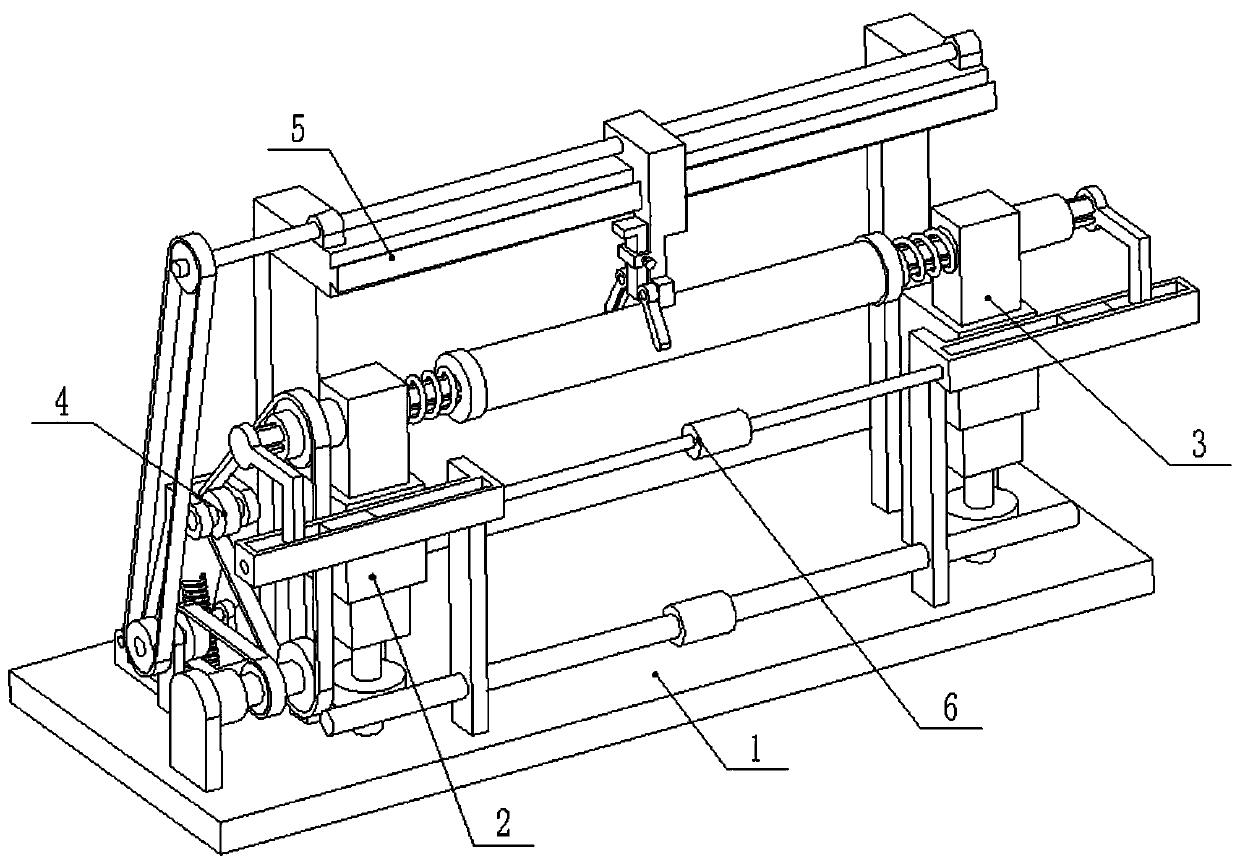

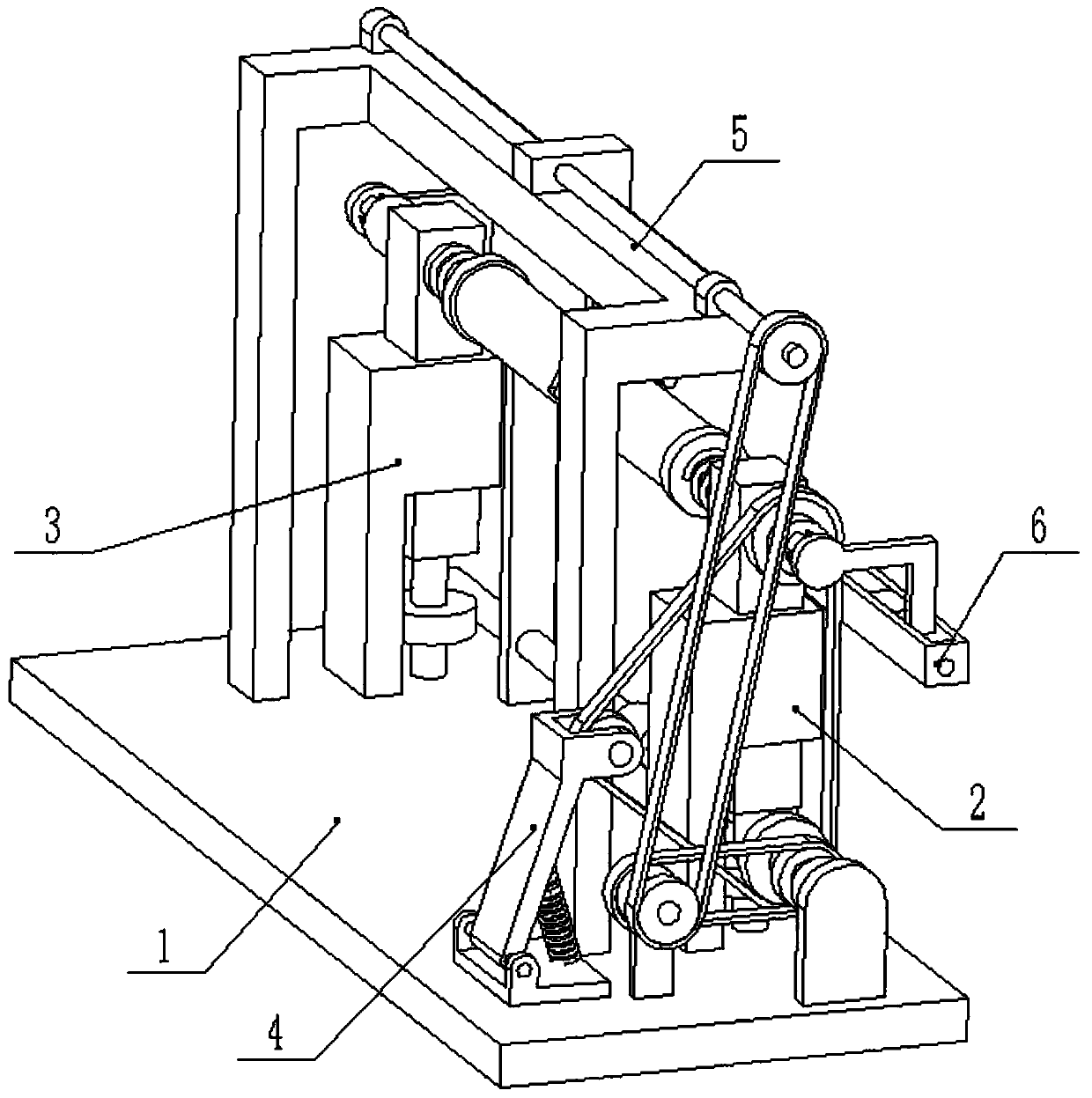

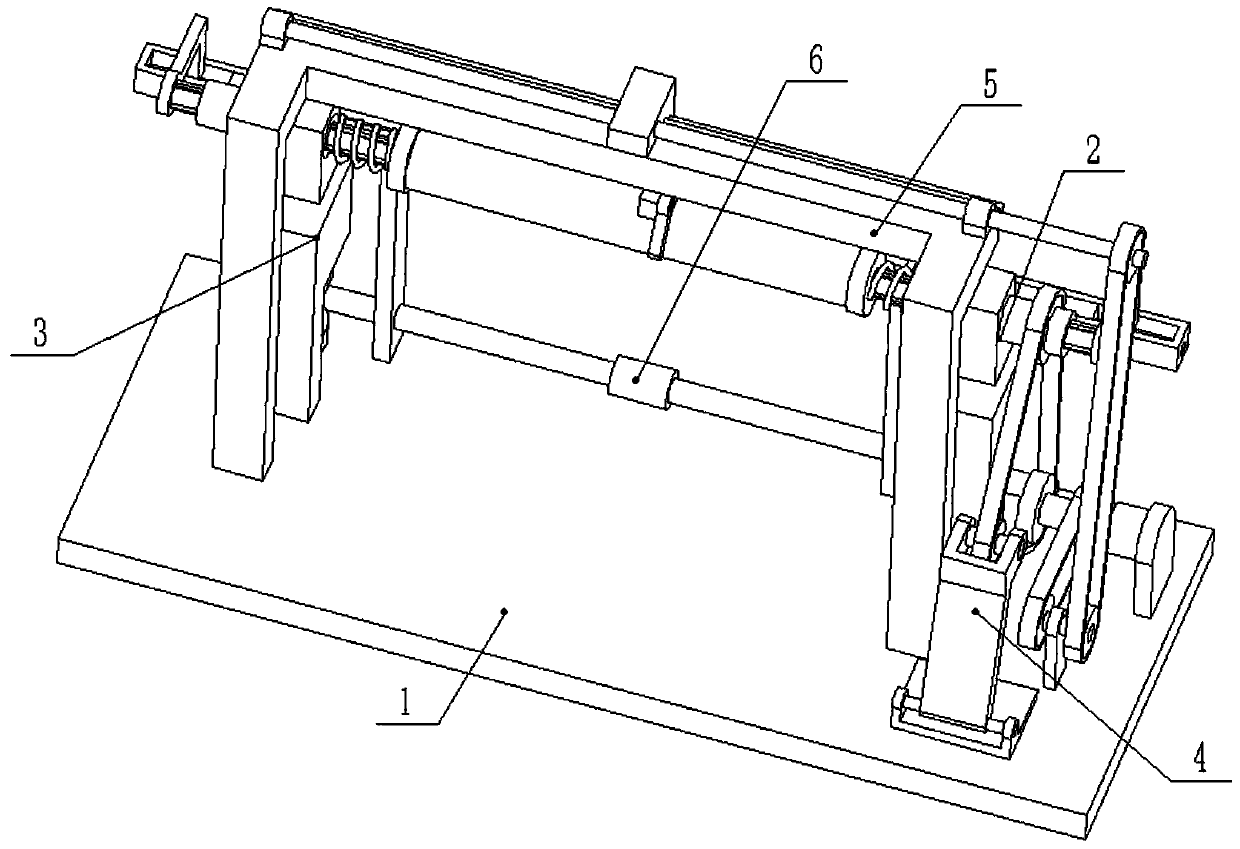

[0032] Combine below Figure 1-14 Explaining this embodiment, a pipe polishing device for building construction includes a base 1, a left support base 2, a right support base 3, a tension wheel 4, a support frame 5, and an adjustment rod 6. The base 1 includes a bottom plate 1- 1. Motor 1-2, driving shaft 1-3, driving pulley I1-4, driving pulley II1-5, driven pulley I1-6, driven pulley II1-7, driven shaft 1-8 and Shaft plate 1-9; the motor 1-2 is fixedly connected to the bottom plate 1-1 through the motor frame, one end of the driving shaft 1-3 is connected to the output shaft of the motor 1-2 through a coupling, the driving shaft 1-3 The other end of the drive shaft is fixedly connected to the driving pulley I1-4, the middle end of the driving shaft 1-3 is fixedly connected to the driving pulley Ⅱ1-5, the driving shaft 1-3, the driving pulley I1-4 and the driving pulley II1-5 They all rotate around their own axis and have axial positioning. The driving pulley II1-5 is connect...

specific Embodiment approach 2

[0037] Combine below Figure 1-14 To illustrate this embodiment, the tensioning wheel 4 includes a supporting seat 4-1, a rotating shaft 4-2, a shaft seat plate 4-3, a shaft fixing seat 4-4, a short shaft 4-5, and a tension pulley 4- 6 and the tension spring 4-7; the support seat 4-1 is fixedly connected to the driving pulley I1-4, the two ends of the rotating shaft 4-2 are respectively connected to the two ends of the support seat 4-1 through the bearing with a seat, the rotating shaft 4-2 rotates around its own axis and has axial positioning. One end of the shaft seat plate 4-3 is fixedly connected to the shaft 4-2, and the other end of the shaft seat plate 4-3 is fixedly connected to the shaft fixing seat 4-4, short The shaft 4-5 is rotatably connected to the shaft fixing seat 4-4 through the bearing with a seat, the tension pulley 4-6 is fixedly connected to the short shaft 4-5, and the short shaft 4-5 and the tension pulley 4-6 are wound around It rotates on its axis and ...

specific Embodiment approach 3

[0039] Combine below Figure 1-14 To explain this embodiment, the left support base 2 also includes a left worm wheel 2-5, the left worm wheel 2-5 is fixedly connected to the left height adjustment screw 2-4, and the left worm wheel 2-5 is located on the left height adjustment seat 2-3 And bottom plate 1-1. The left worm wheel 2-5 rotates around its own axis and has axial positioning.

[0040] The right support seat 3 also includes a right worm gear 3-5, the right worm gear 3-5 is fixedly connected to the right height adjustment screw 3-4, and the right worm gear 3-5 is located on the right height adjustment seat 3-3 and the bottom plate 1-1 between. The right worm wheel 3-5 rotates around its own axis and has axial positioning.

[0041] The pipe polishing device for building construction also includes an adjusting rod 6. The adjusting rod 6 includes a vertical frame plate 6-1, a worm 6-2, a screw ring I 6-3, a sliding seat 6-4, and an adjusting rod 6 Screw 6-5, screw ring Ⅱ 6-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com