Efficient grinding and rust removing equipment for steel bars for building

A technology for construction and steel bars, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of low grinding efficiency, affecting structural safety, high production cost, etc., and achieve the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

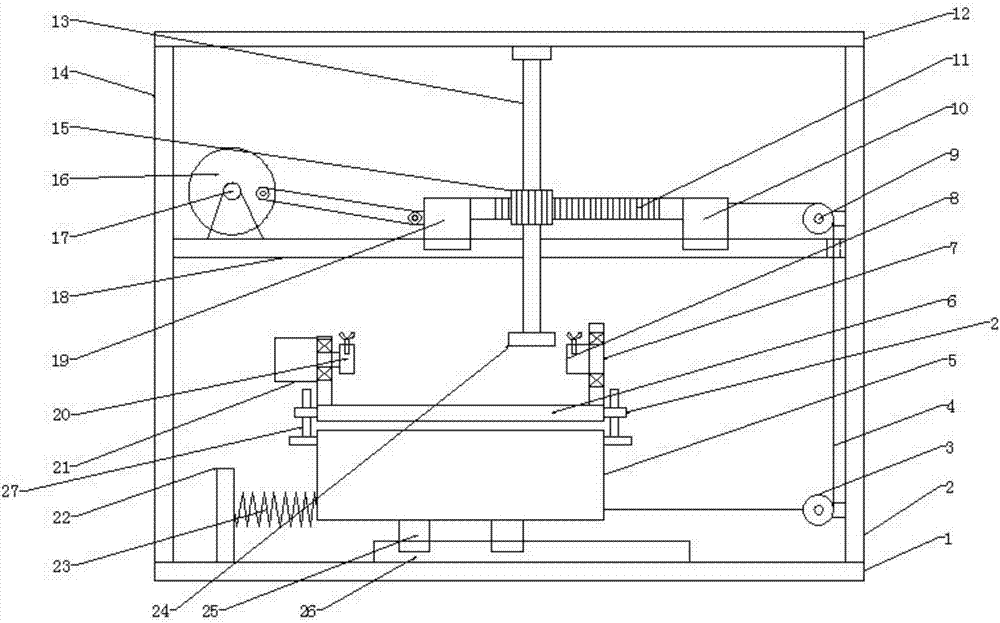

[0020] see Figure 1~2 , in the embodiment of the present invention, a kind of high-efficiency grinding and derusting equipment for steel bars for construction includes a bottom plate 1, a workbench 6 and a grinding disc 24, the upper left side of the bottom plate 1 is provided with a left side Side plate 2, top plate 12 is fixed on the top of left side plate 14 and right side plate 2, and slide rail 26 is arranged in the middle of described base plate 1 top, slide rail 26 is slidably connected with first slide block 25, and first slide block 25 is fixed. At the bottom of the box body 5, a first spring 23 is connected to the lower left part of the box body 5, and the other end of the first spring 23 is connected to the fixed rod 22 on the bottom plate 1. A workbench 6 is arranged above the box body 5, and both sides of the lower part of the workbench 6 A sleeve 28 is provided, and a slide bar 27 is set inside the sleeve 28. The bottom end of the slide bar 27 is fixedly connect...

Embodiment 2

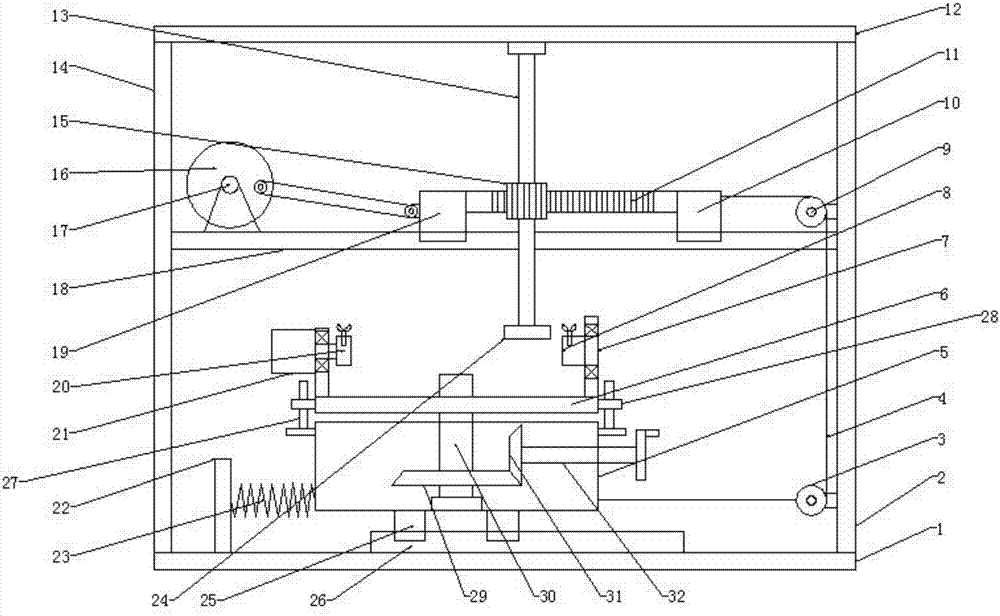

[0022] see image 3, based on Embodiment 1, a second bearing seat is installed at the bottom of the inner cavity of the box body 5, a threaded rod 30 is installed on the second bearing seat, and a first helical gear 29 is installed on the bottom of the threaded rod 30, and the first helical gear 29 and The second helical gear 31 is meshed, and a connecting shaft 32 is fixed in the middle of the right side wall of the second helical gear 31. The other end of the connecting shaft 32 runs through the box body 5 and is connected with the rotating handle. The connecting shaft 32 is rotatably connected with the box body 5. The threaded rod The top of 30 runs through the box body 5 and the workbench 6 and is spirally connected with the workbench 6. The threaded rod 30 is rotatably connected with the box body 5. When the handle is rotated, the handle drives the connecting shaft 32 to rotate, and the connecting shaft 32 drives the second helical gear 31 to rotate. , the second helical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com