Constant-force grinding device and grinding control method thereof

A technology of a grinding device and a control method, which is applied in the direction of a grinding device, a grinding automatic control device, program control, etc., can solve problems such as uncontrollable grinding force, and achieve the effect of improving the grinding quality and changing the grinding force smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

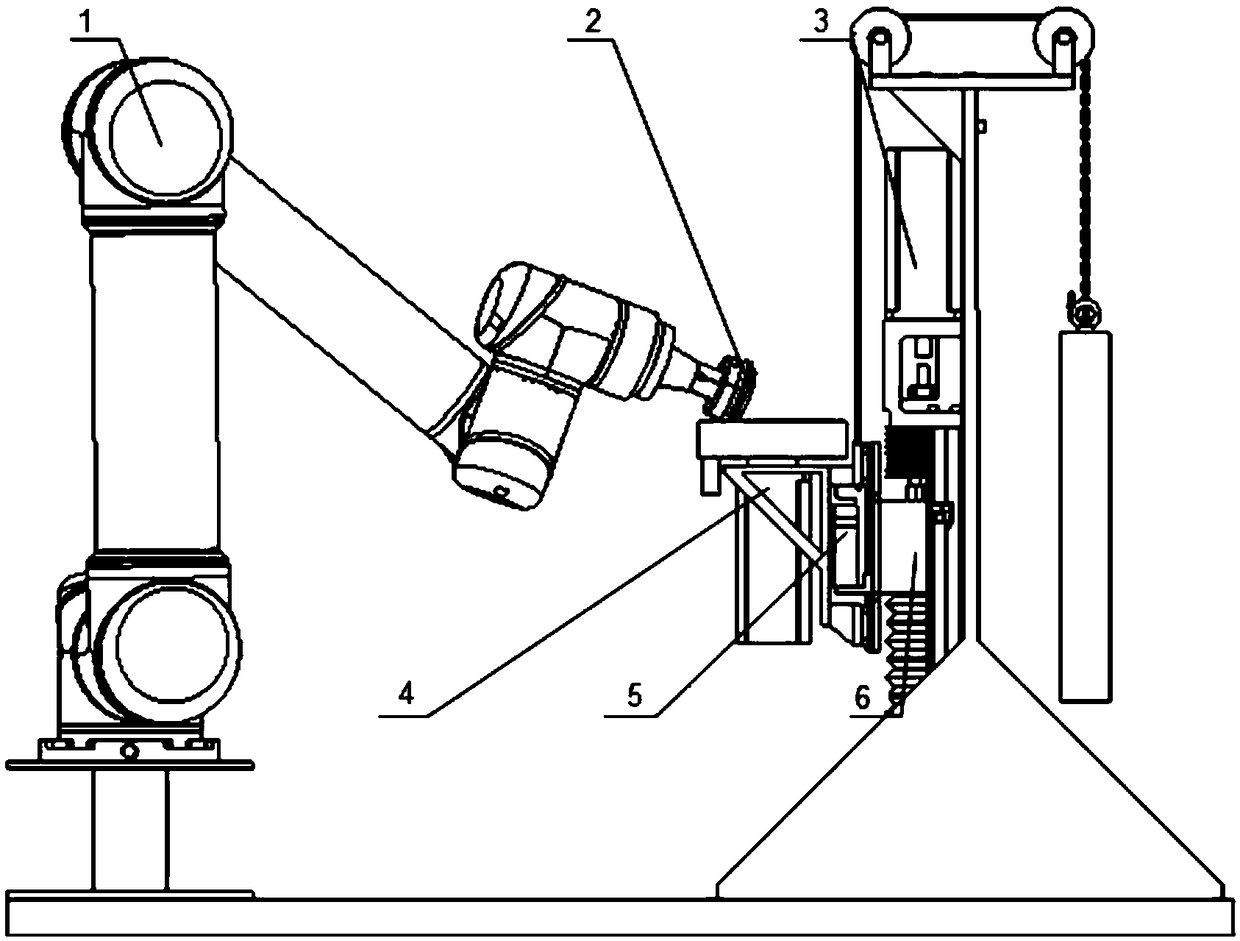

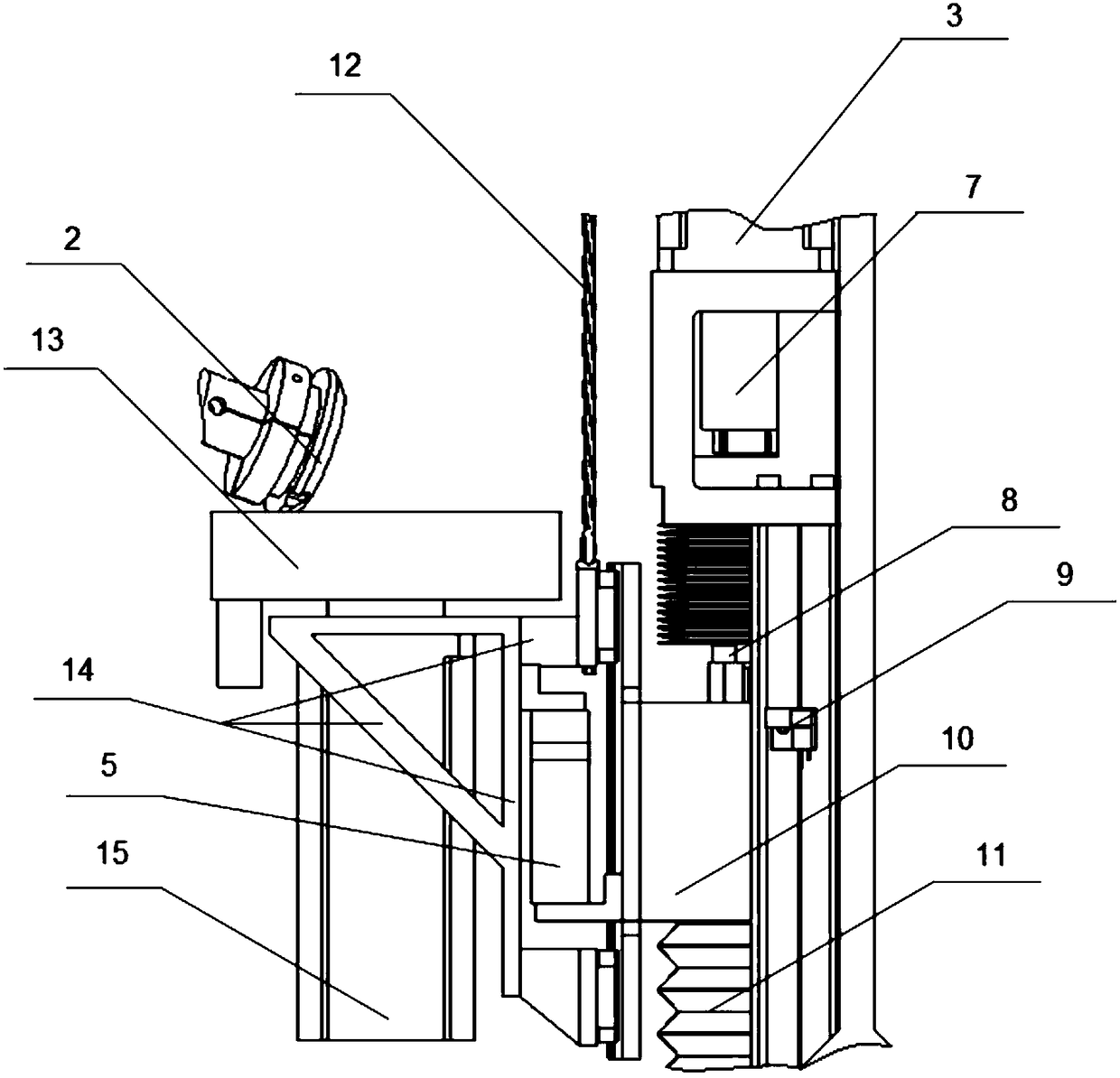

[0067] Such as Figure 1-2 As shown, a constant force grinding device includes a six-degree-of-freedom industrial robot 1, a floating grinder, a one-dimensional force sensor 5, a data acquisition device, a constant force device and a controller;

[0068] The floating grinding table on the floating grinding machine rotates at a constant speed, the end of the six-degree-of-freedom industrial robot clamps the workpiece 2 to be ground, and the workpiece to be ground is ground on the grinding sand table 13 of the floating grinding table 4; a one-dimensional force sensor is installed on the lower side of the floating grinding machine , the one-dimensional force sensor is connected to the controller through a data acquisition device, the constant force device includes an AC servo motor 3 and a linear motion module 6, and the linear motion module is driven by the AC servo motor 3 to adjust the workpiece to be ground and the floating grinding table The relative position of the AC servo...

Embodiment 2

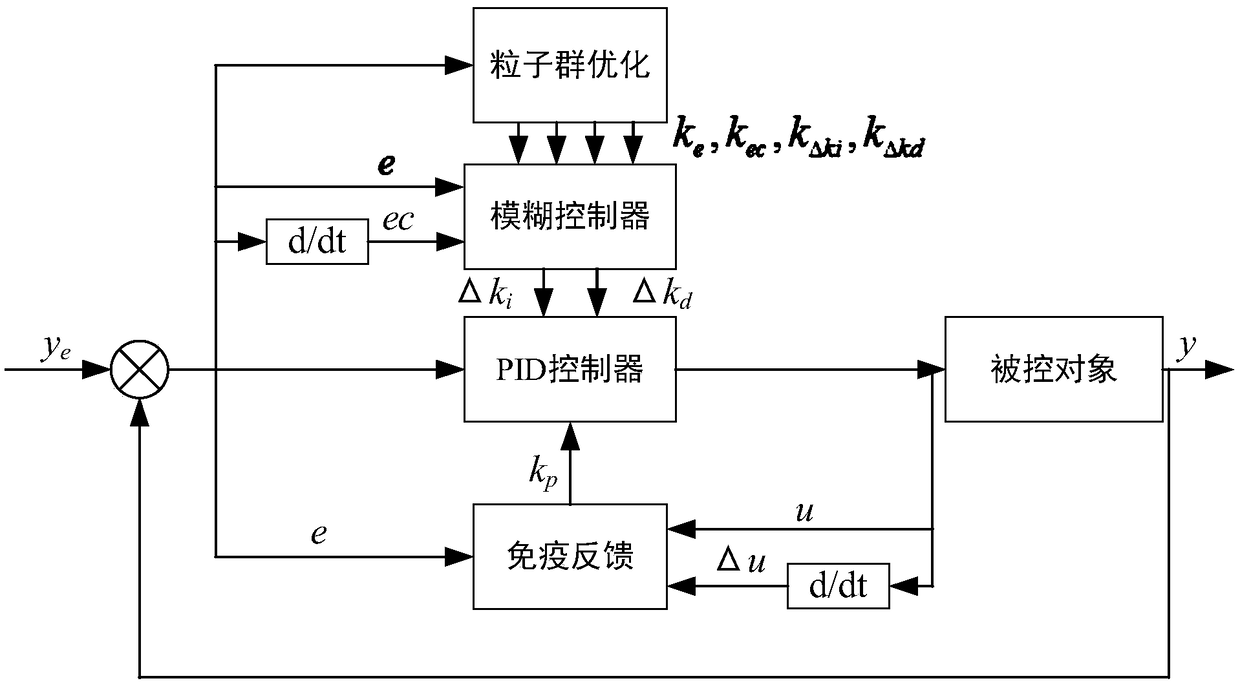

[0074] Such as figure 2 Shown, a kind of grinding control method based on the constant force grinding device of embodiment 1 comprises the following steps:

[0075] S1. Control the workpiece to be ground at the end of the industrial robot to enter the floating grinding table for grinding according to the pre-track;

[0076] S2. The one-dimensional force sensor obtains the grinding force analog signal;

[0077] S3. Calculate the grinding force error and the error change value according to the currently collected grinding force analog signal and the expected value, and use it as the input of the adaptive PID controller;

[0078] S4. The output of the adaptive PID controller is the control quantity of the AC servo motor. The AC servo motor drives the linear motion module to adjust the relative position of the workpiece to be ground and the floating grinding table in real time according to the above control quantity, thereby controlling the grinding force.

[0079] The processa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com