Numerical control polishing machine

A grinding machine and reducer technology, which is applied to the parts of grinding machine tools, grinding machines, grinding heads, etc., can solve the problems of difficulty in adapting to different sizes and different types of parts at the same time, poor flexibility, and physical injuries of workers, etc., to achieve the goal of feeding And fast and accurate positioning, improved production efficiency, and improved grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

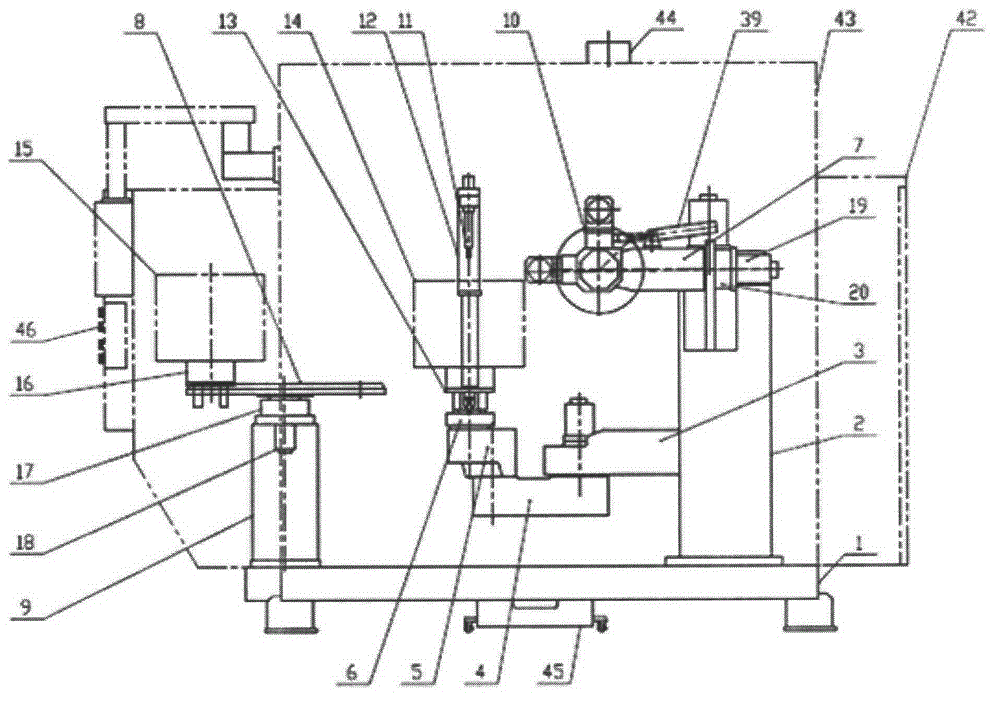

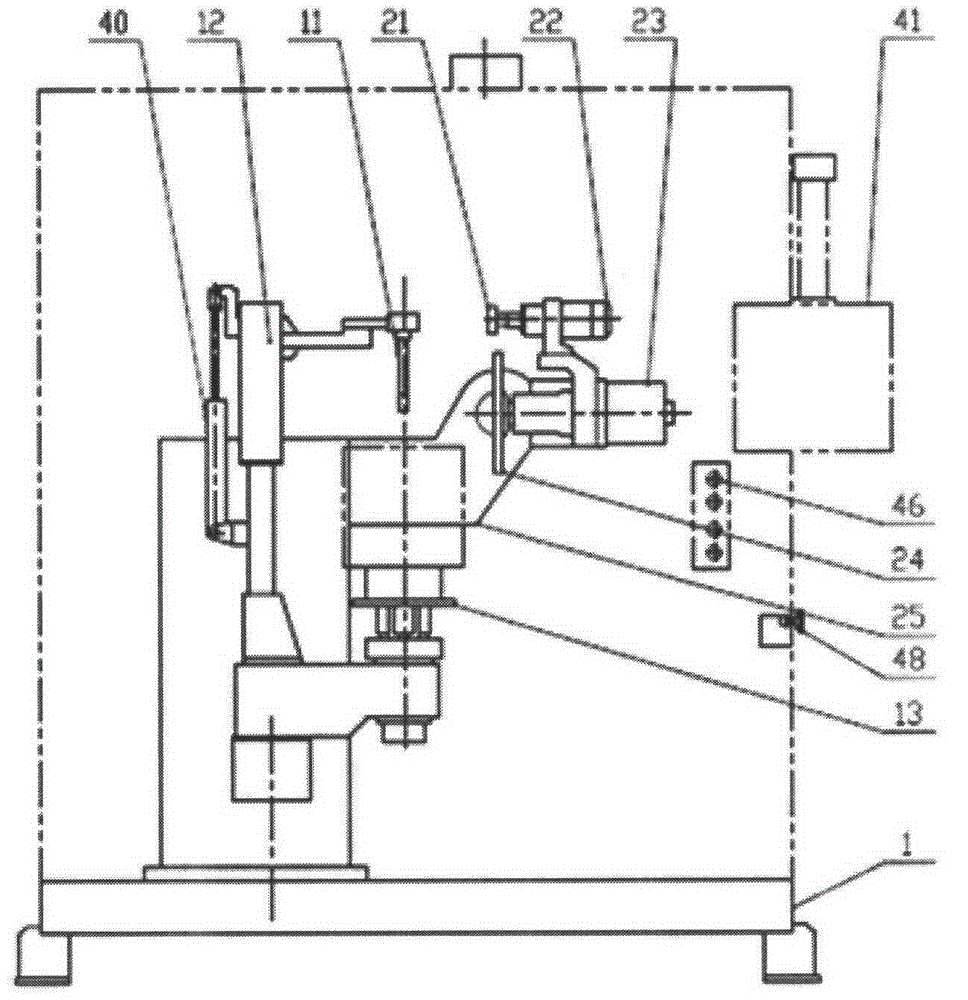

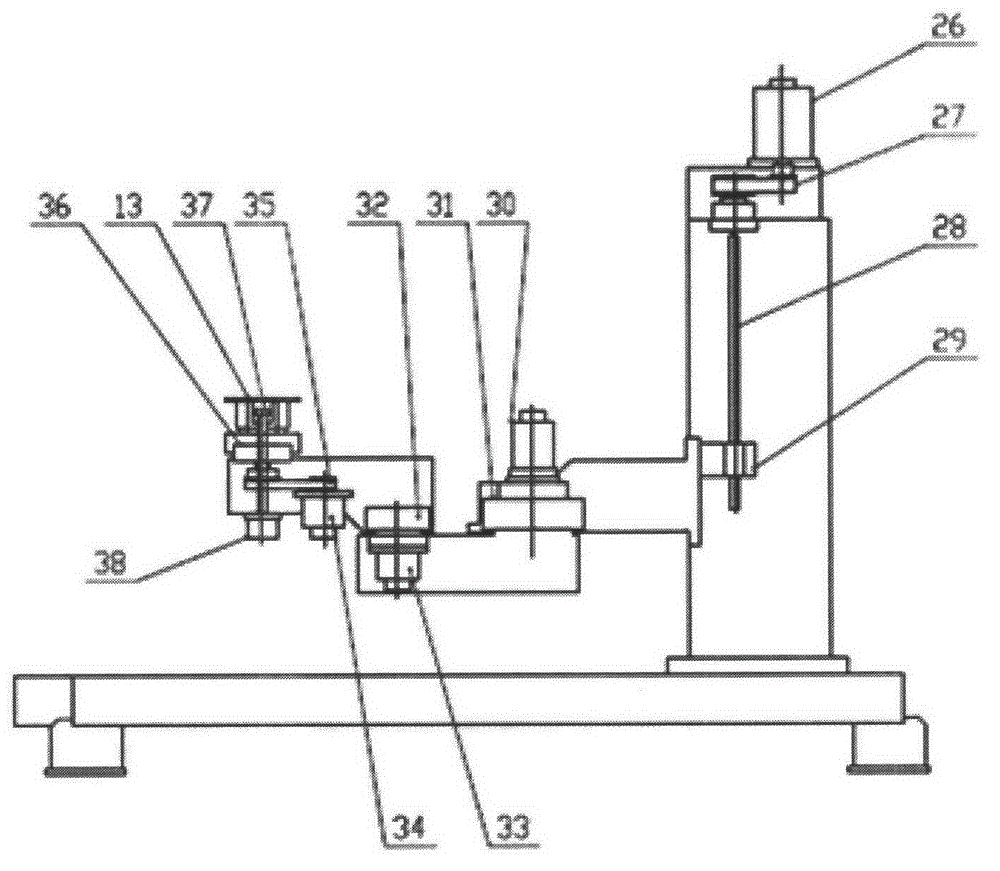

[0036] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

[0037] Such as Figure 1~4 Shown, a kind of numerical control grinder, it comprises:

[0038] Workpiece four-axis shifting device, the workpiece four-axis shifting device includes column 2, Y-axis slide 3, X-axis swing arm 4, Z-axis swing arm 5, A-axis rotary table 6, Y-axis drive assembly, X-axis The drive assembly, the Z-axis drive assembly and the A-axis drive assembly, the A-axis rotary table 6 is used to clamp the workpiece, the Y-axis slide seat 3 is slidingly fitted on the column 2, and the X-axis swing arm 4 is swingably supported on the Y-axis slide On the seat 3, the Z-axis swing arm 5 is swingably supported on the X-axis swing arm 4, the A-axis rotary table 6 is rotatably supported on the Z-axis swing arm 5, and the Y-axis drive assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com