Counter-position placement abrasive belt grinding robot

A technology of abrasive belt grinding and robots, which is applied in the direction of abrasive belt grinders, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problems of low production efficiency and high labor intensity, so as to improve production efficiency and reduce labor intensity , to achieve the effect of automatic grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The existing technology of grinding hardware products is: through the rotation of the abrasive belt machine, the workpiece is manually sent to the front end of the abrasive belt for grinding. The labor intensity of the employees of the enterprise is high and the production efficiency is low.

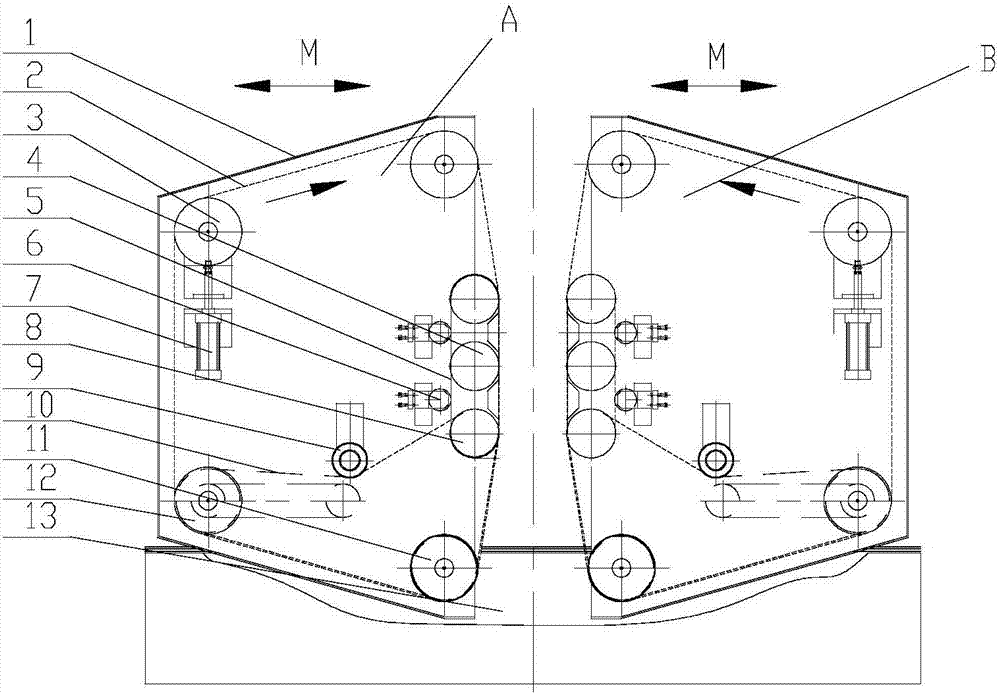

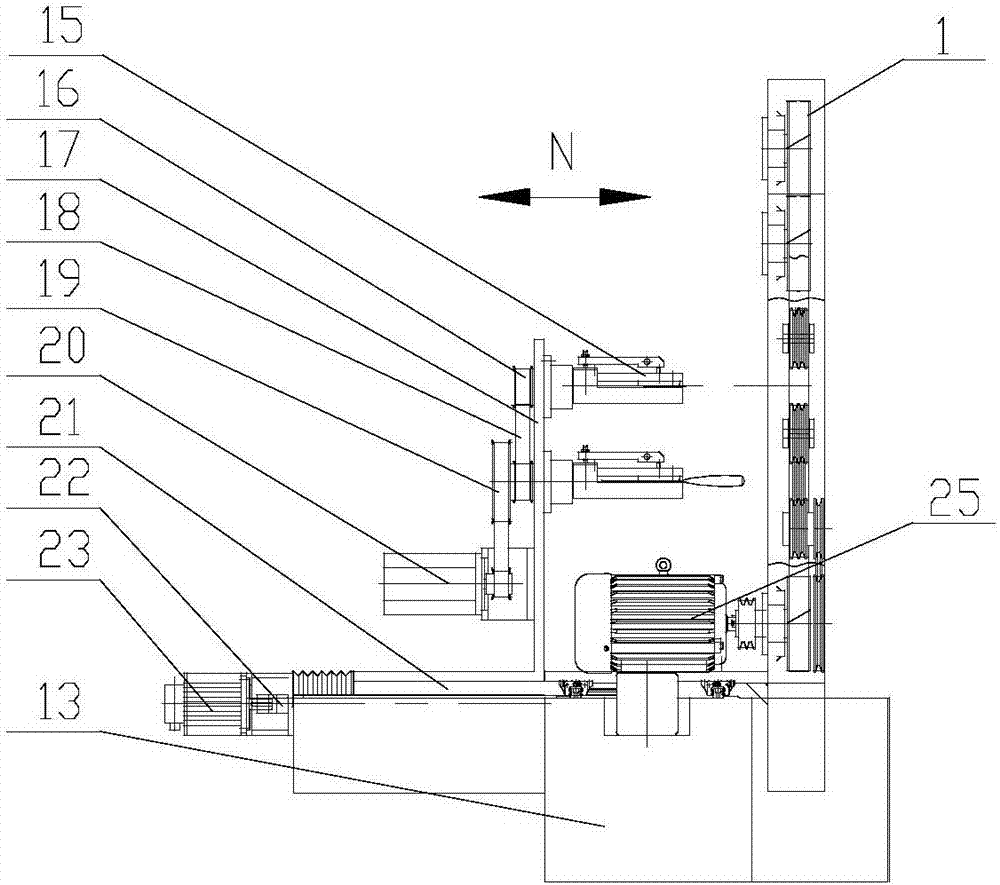

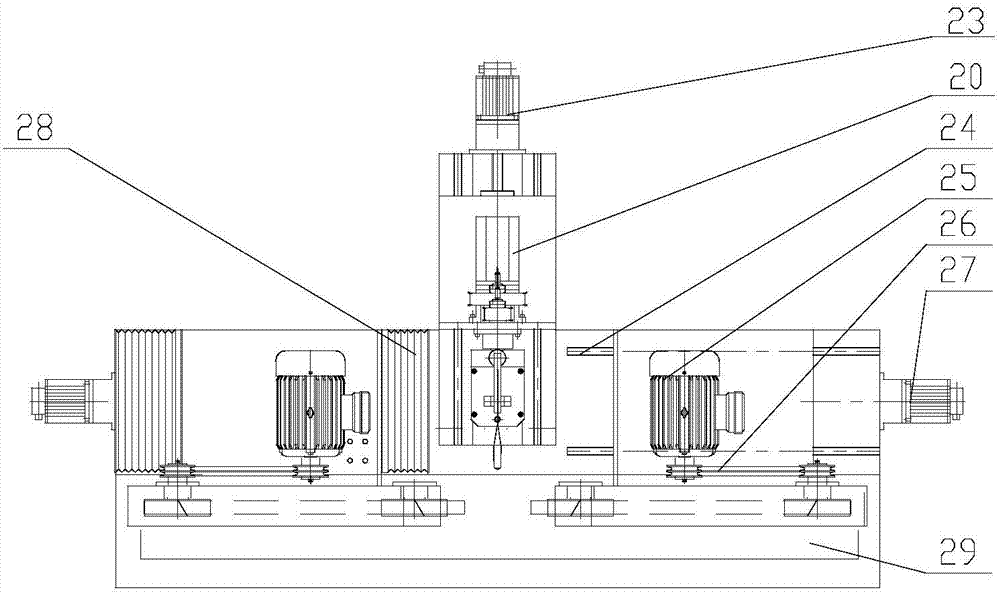

[0034] The design concept of the present invention is: aiming at the problems of high labor intensity and low production efficiency caused by manually sending the workpiece to the front end of the abrasive belt for grinding, the present invention realizes grinding through the left grinding unit and the right grinding unit. The main cutting movement, the left grinding unit and the right grinding unit can realize the lateral feed movement under the drive of the servo motor; the manipulator fixture realizes the longitudinal movement through the servo motor drive, this movement is the feeding movement of the workpiece, and the manipulator fixture can realize the rotation at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com