Watchcase grinding equipment and application thereof

A watch case and equipment technology, applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems that affect the accuracy of watch case grinding, cannot realize automatic grinding, and reduce grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

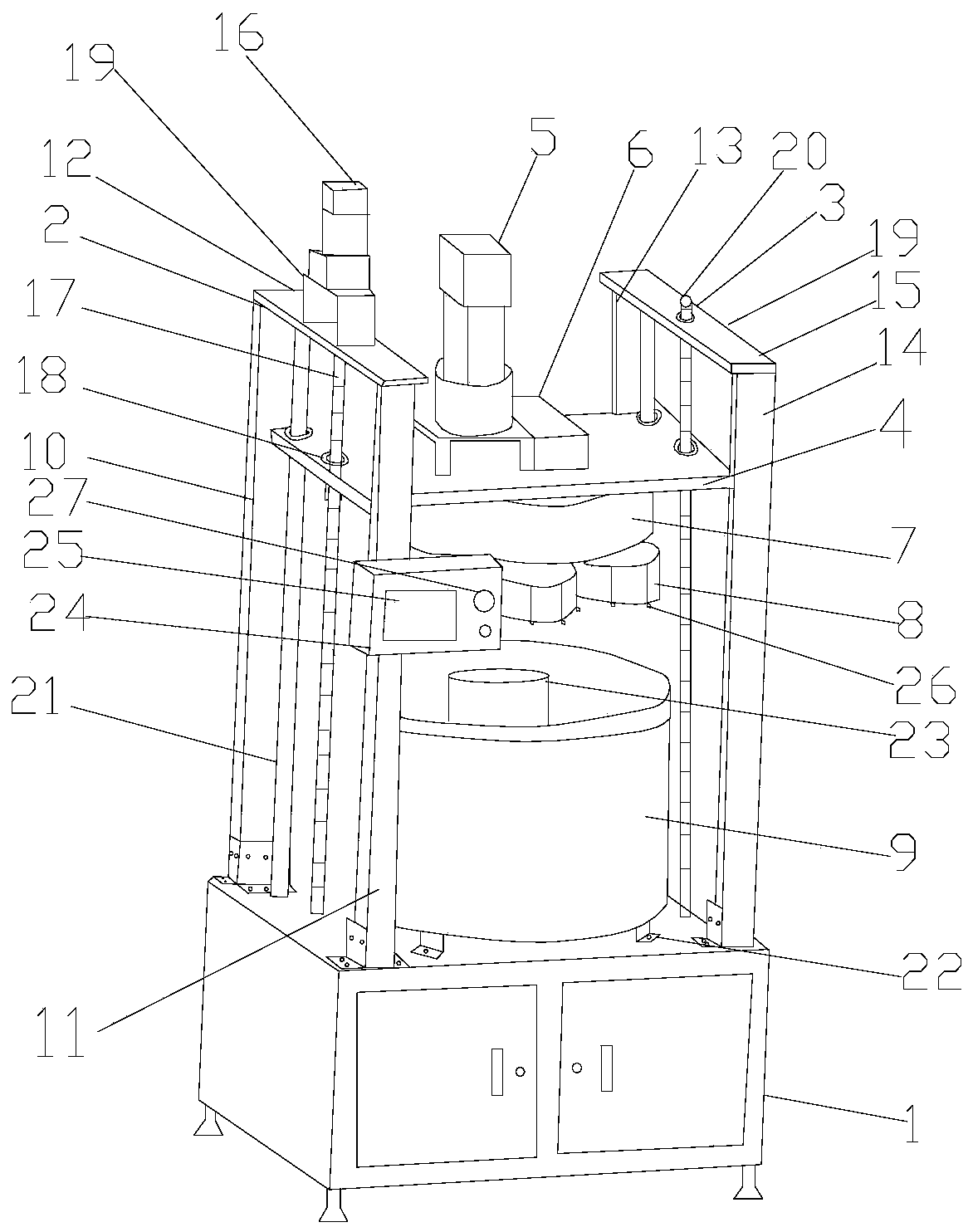

[0038] A watch case grinding equipment, comprising a grinding machine bracket 1, a supporting device installed on the upper part of the grinding machine bracket 1, a grinding device and a first driving device installed on the supporting device, and a container for holding abrasive materials located below the grinding device device, a clamping device 26 for clamping the watch case is installed on the polishing device.

[0039] The support device includes a first support device 2 and a second support device 3 installed above the grinder support, and a support plate 4 between the first support device 2 and the second support device 3 . The structure of the first supporting device 2 is the same as that of the second supporting device 3, and the first supporting device 2 includes a first supporting column 10 connected to the top of the grinder support 1, a second supporting column 11, a connection between the first supporting column 10 and the The first fixed plate 12 of the second...

Embodiment 2

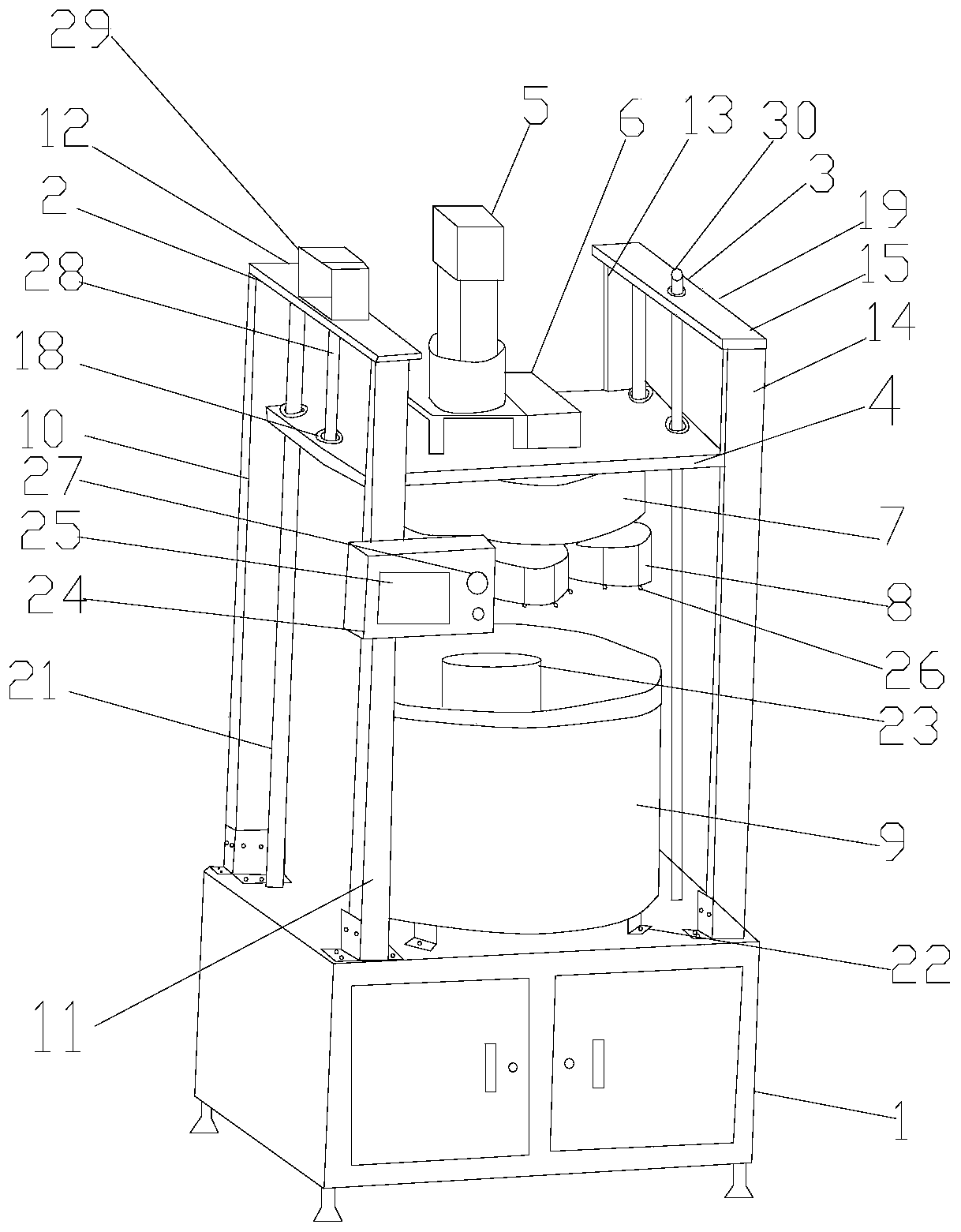

[0046] In this embodiment, only the technical points different from those in Embodiment 1 are stated, and the technical features not described in detail in this embodiment are all the same as those in Embodiment 1. In this embodiment, a second linear stepping motor is installed on the second fixing plate, and the power output end of the second linear stepping motor is connected to the upper end of the second screw rod. There are six second rotating devices in this embodiment. 6 clamping devices are installed on each second rotating device. The bottom of the first receiving tray is fixedly connected with 6 fixing parts, and the fixing parts are connected with the upper part of the grinder support through screws.

Embodiment 3

[0048] In this embodiment, only the technical points different from those in Embodiment 1 are stated, and the technical features not described in detail in this embodiment are all the same as those in Embodiment 1. There are 10 second rotating devices in this embodiment. 10 clamping devices are installed on each second rotating device. The bottom of the first receiving tray is fixedly connected with 10 fixing parts, and the fixing parts are connected with the upper part of the grinding support through screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com