Automatic glass grinding machine

A grinding machine and glass technology, which is applied to the parts of grinding machine tools, grinding machines, and machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of low automation and poor grinding efficiency, and achieve low labor intensity and high grinding efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

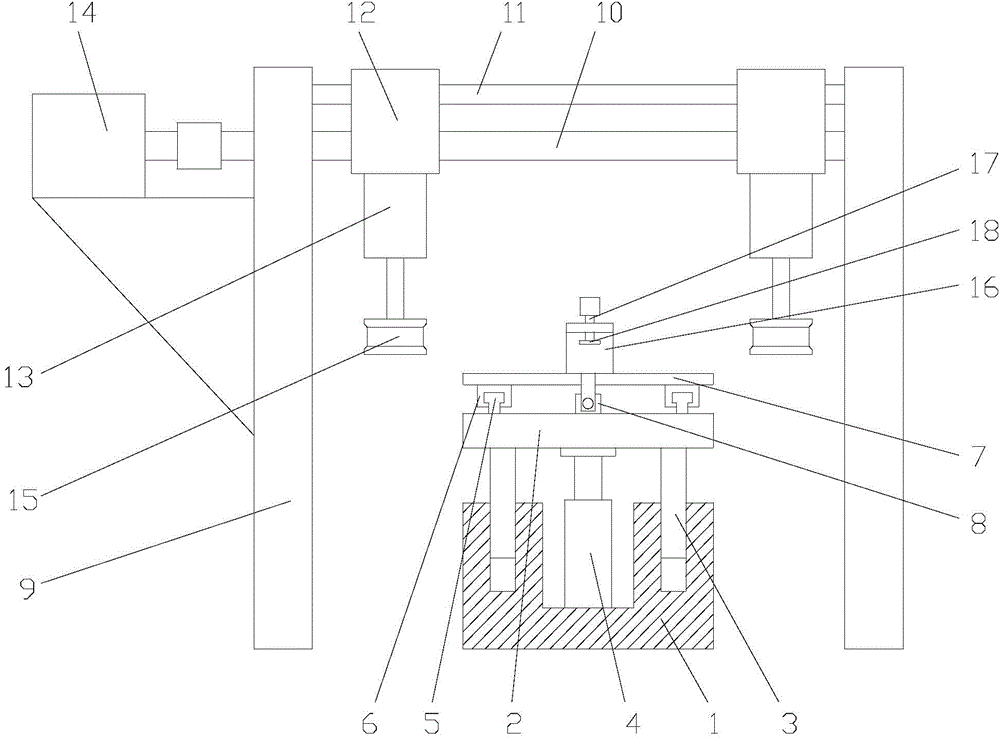

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] As shown in the figure, the automatic glass grinding machine of this embodiment includes a base 1 and a lifting table 2. The lower part of the lifting table is provided with a guide column 3 that slides up and down with the base. The lifting cylinder 4 connected to the workbench, the upper part of the lifting workbench is provided with two parallel guide rails 5, the guide rails are provided with a slide block 6 slidingly matched with it, and the slide block is fixedly connected with a carrier plate 7 , the carrier plate is provided with a pressing device, and the lifting table is also provided with a feed cylinder 8 that drives the carrier plate to reciprocate and slide along the guide rail;

[0012] Also comprise the vertical frame 9 that is fixed on base both sides, the leading screw 10 that is arranged on the vertical frame by bearing, the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com