Building aluminum formwork working face machining device and method

A technology of processing device and aluminum formwork, which is applied to the cleaning method of tools, grinding drive device, metal processing equipment, etc., can solve the problem that the automatic grinding of aluminum formwork cannot be realized, the labor intensity of staff is increased, and the flatness of grinding is inconsistent. and other problems, to achieve the effect of good grinding flatness, solving inconsistency in flatness, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

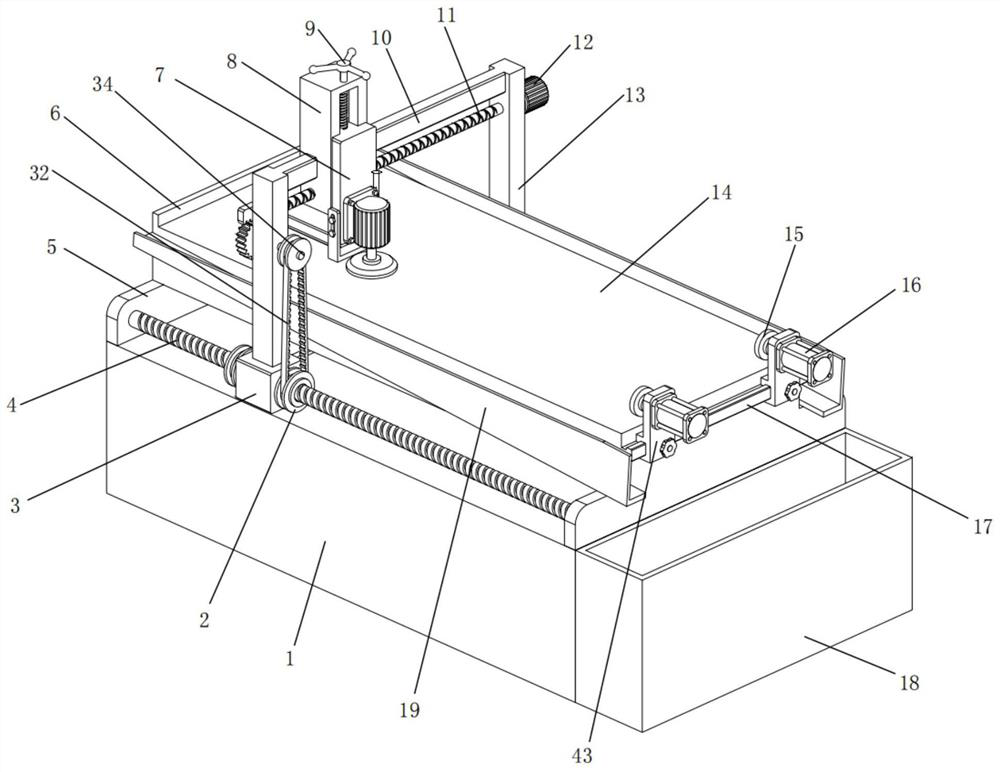

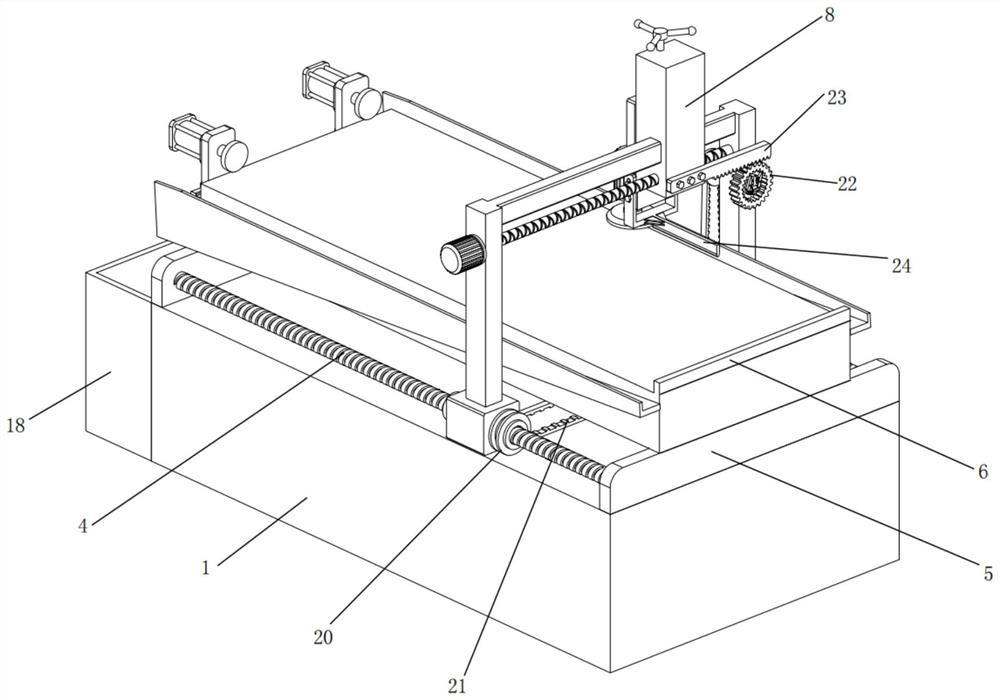

[0035] see Figure 1-Figure 8 , in an embodiment of the present invention, a working surface processing device for building aluminum formwork, comprising a workbench 1, the two sides of the upper end surface of the workbench 1 are fixedly connected with mounting plates 5, and the two ends of the two mounting plates 5 are rotationally connected There is a first threaded rod 4, and a grinding table 14 is fixedly connected between the middle positions of the upper ends of the two mounting plates 5. One side of the upper end surface of the grinding table 14 is provided with a rib 6, and the other side of the upper end surface of the grinding table 14 The side is also provided with a fixing assembly for fixing the aluminum formwork; both sides of the grinding table 14 are fixedly connected with a discharge chute 19, and one side of the workbench 1 is also provided with a collection box 18 at the position below the lower port of the discharge chute 19 .

[0036]Through the set proc...

Embodiment 2

[0047] The difference from Embodiment 1 is that: the collection box 18 is provided with a filter plate for filtering the cooling liquid flowing out of the discharge trough plate 19, and the collection box 18 is also provided with a drain; The filter plate set in 18 can filter debris and coolant, making it more convenient to use.

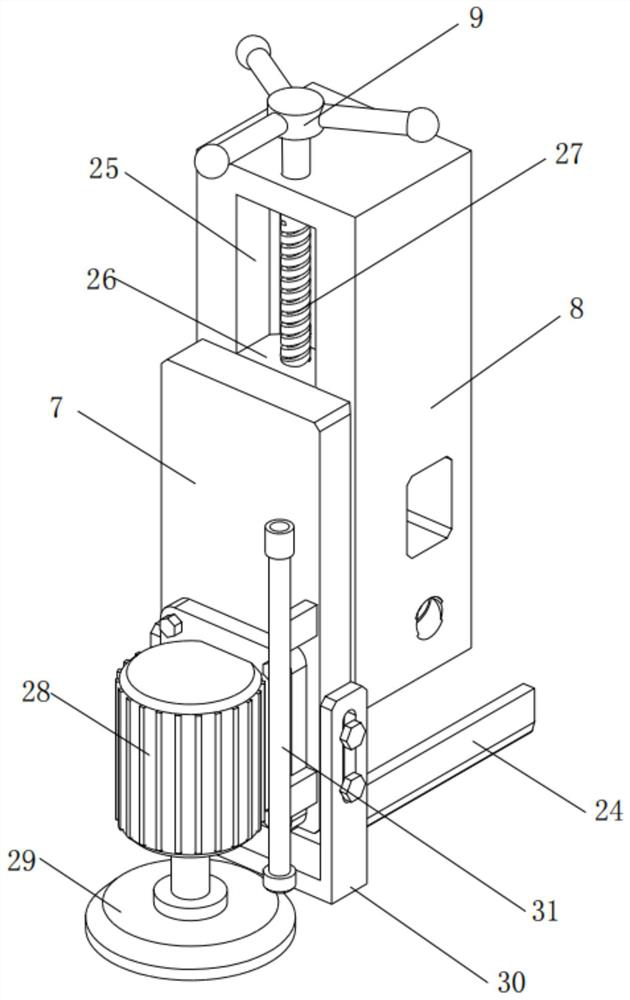

[0048] The working principle of the present invention is: when the present invention is in use, the aluminum formwork that needs to be processed is placed on the grinding table 14, and then one end of the two aluminum formworks is set on the rib 6, and then the top plate 15 is pushed by the output end of the cylinder 16 Fix the aluminum formwork, then rotate the handle 9 to rotate the second threaded rod 27 to adjust the position of the mounting plate 7, so that the grinding disc 29 moves to the processing height, and then start the grinding motor 28 to drive the grinding disc 29 to rotate at a high speed. Then drive the reciprocating screw mandrel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com