Automatic grinding device and method thereof

An automatic and grinding tool technology, applied in the direction of grinding machines, grinding feed movement, grinding workpiece support, etc., can solve the problems of workpiece surface grinding differences, manual grinding work efficiency, etc., to solve the differences in workpiece surface grinding, solve Work efficiency is low, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

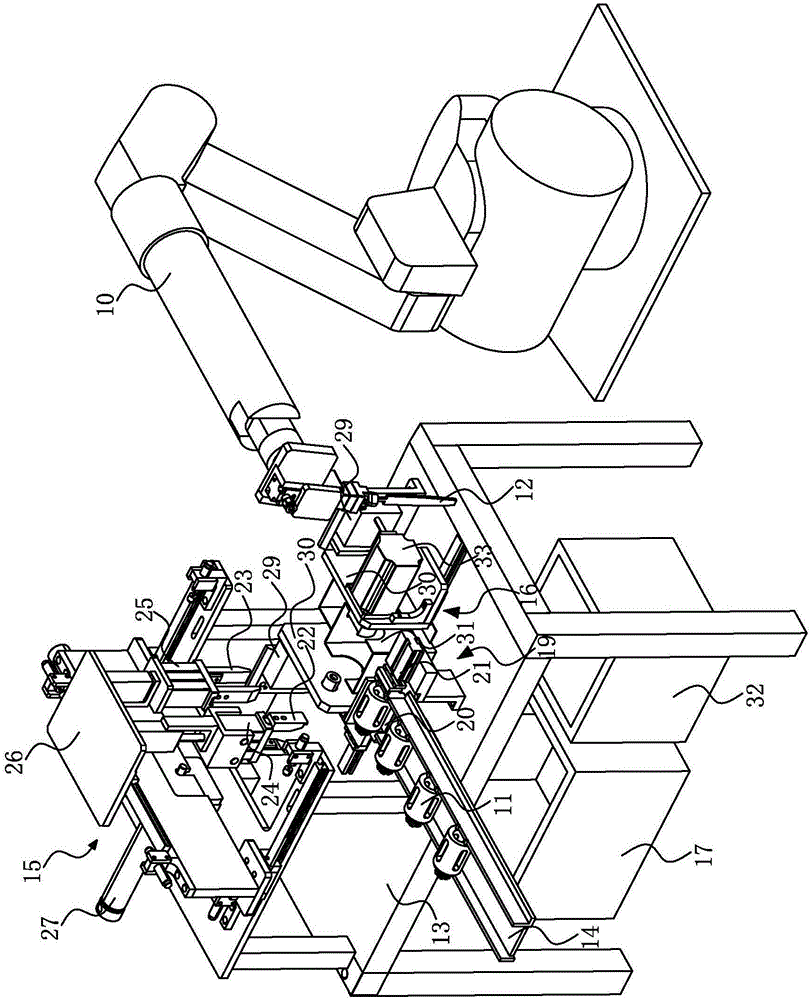

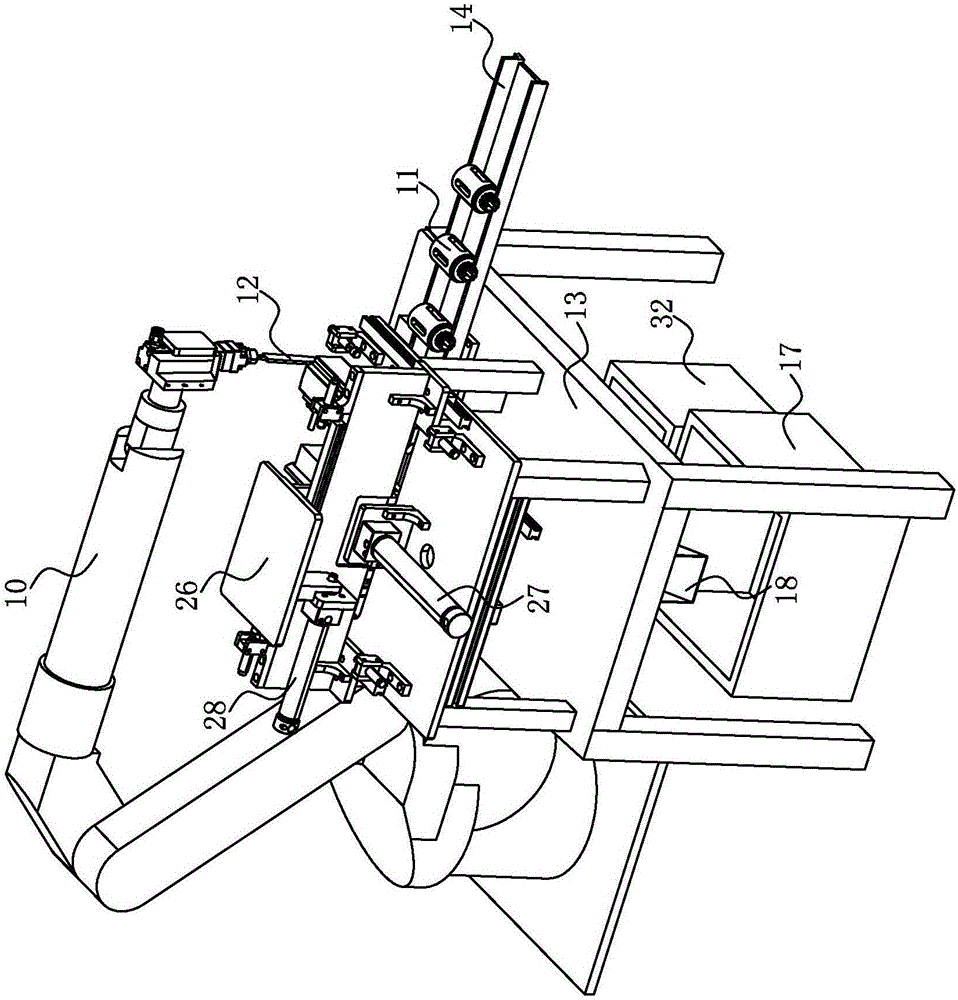

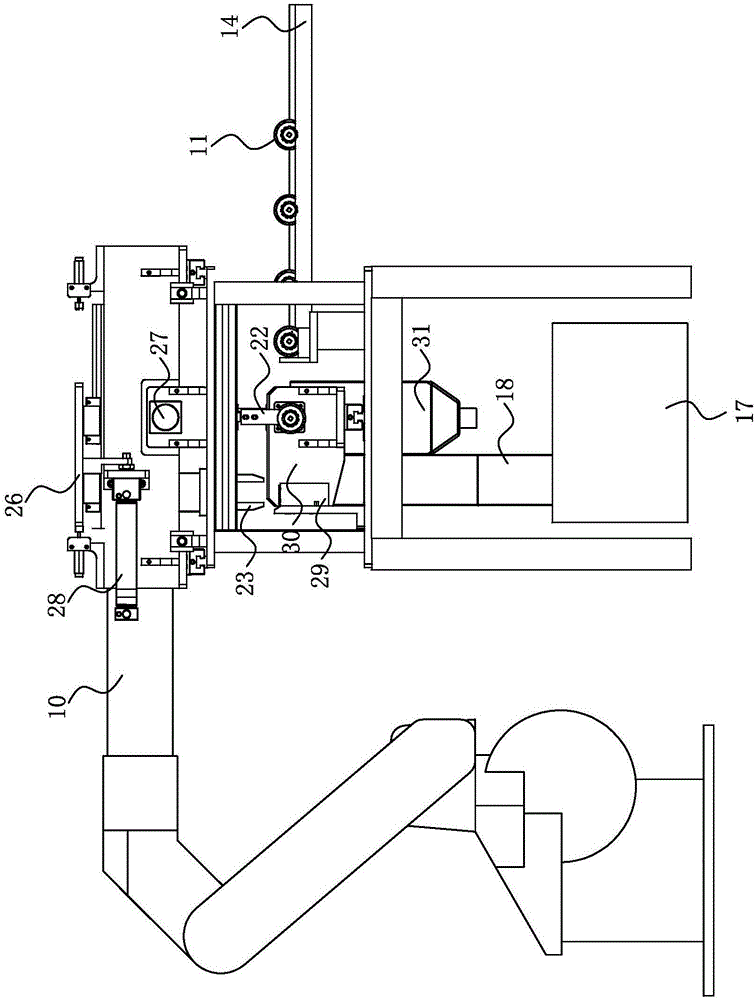

[0040] see figure 1 , figure 2 and image 3 shown, where figure 1 A schematic structural view of the first working state and the first angle of the automatic polishing device of the present invention is drawn, figure 2 A schematic structural view of the second angle of the first working state of the automatic polishing device of the present invention is drawn, image 3 A schematic structural view of the third angle of the first working state of the automatic grinding device of the present invention is shown.

[0041] In a preferred embodiment, the automatic grinding device of the present invention cooperates with the mechanical arm 10 to grind the workpiece 11. The mechanical arm 10 can be a six-axis mechanical arm to achieve rotation and displacement at any angle. The automatic grinding device include:

[0042] A grinding tool 12, which is clamped at the end of the mechanical arm 10, the grinding tool 12 may be a file, but is not limited thereto;

[0043] Workbench 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com