Automatic girth welding device for air cylinder for automobile

A gas storage tank and girth welding technology, applied in the field of auto parts manufacturing, can solve the problems of uneven quality, low quality, on the other hand, welding quality, depending on the operation level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

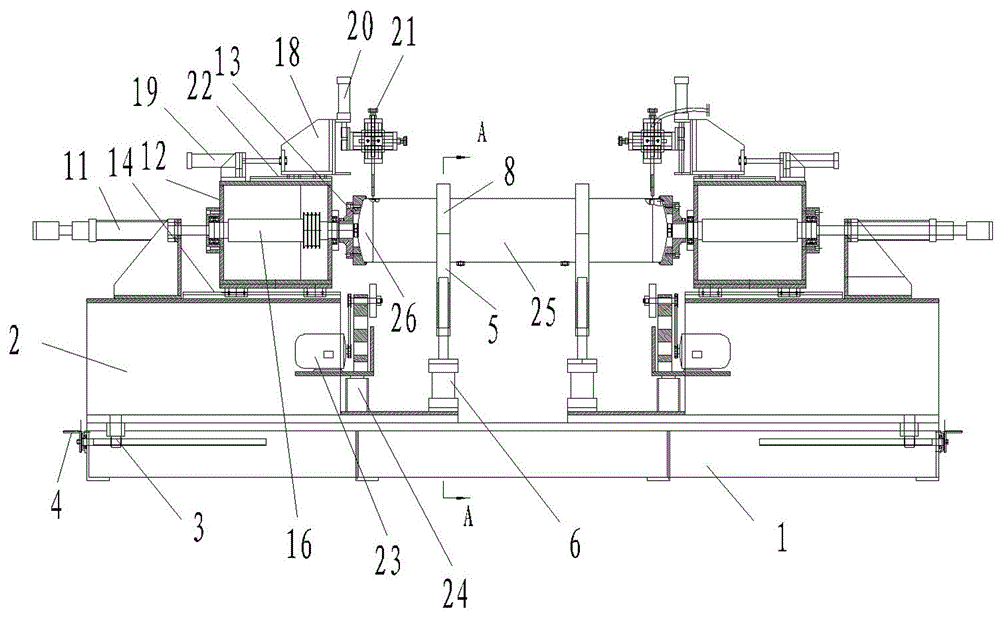

[0020] like figure 1 As shown, the present invention provides an automatic girth welding device for a gas cylinder for automobiles, comprising:

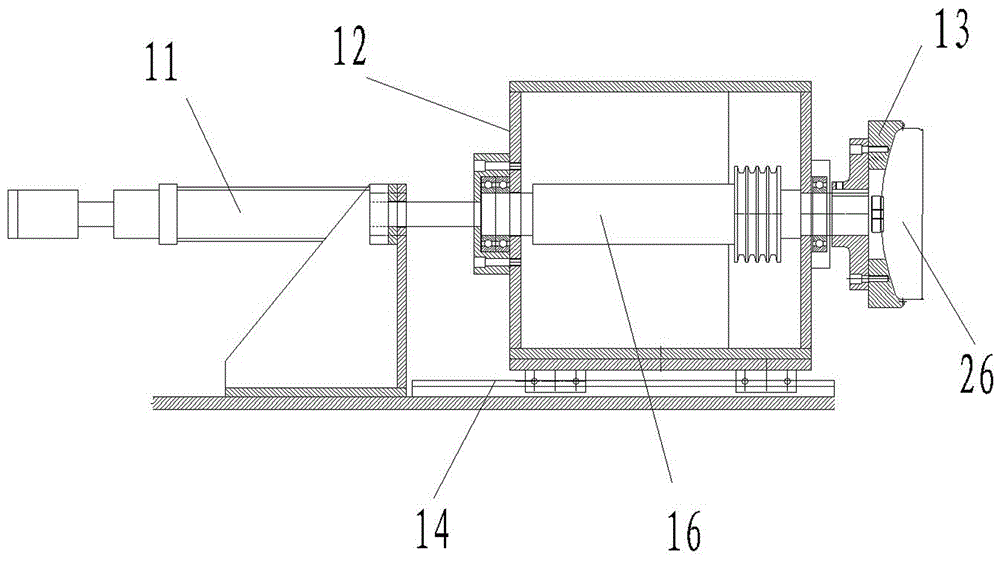

[0021] a. Base 1. There are two symmetrical bases 2 at intervals on the base 1; Move back and forth along the axial direction of the gas storage cylinder to be welded;

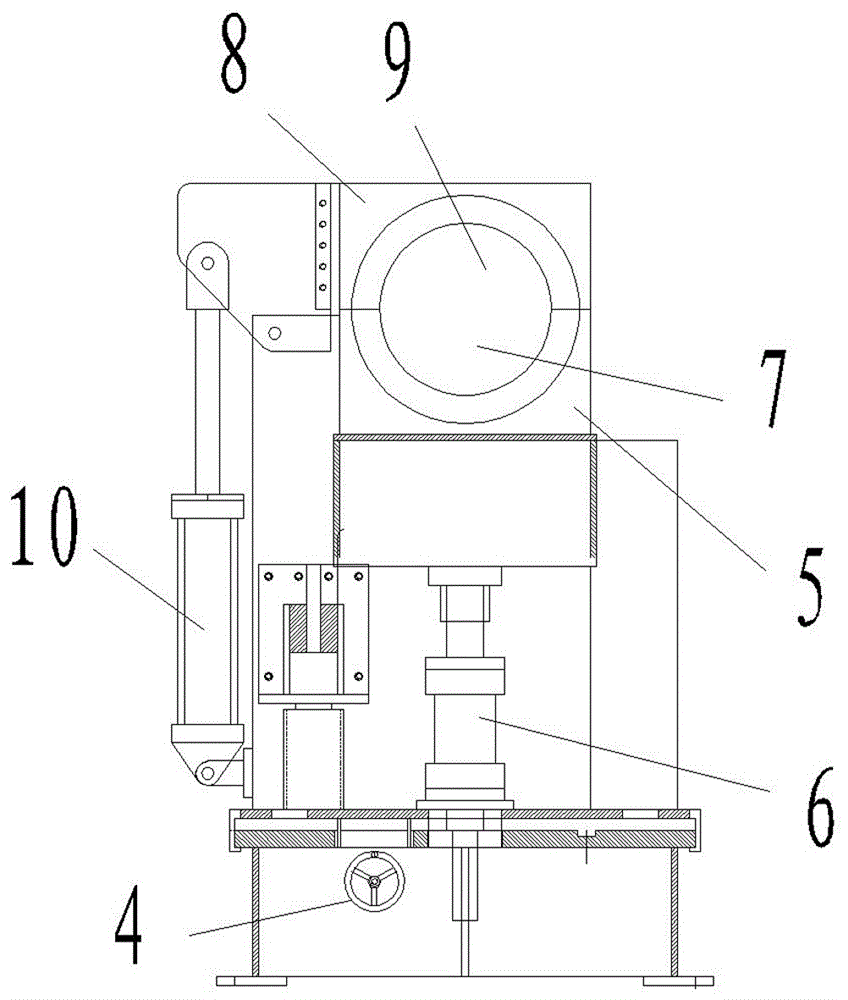

[0022] b. Combine figure 2 As shown, the air storage tank bracket 5 located between the two bases, the air storage tank bracket 5 can be provided with more than one at intervals according to needs, and two are selected in this embodiment; the bottom of the gas storage tank bracket 5 is provided with a lifting cylinder 6, and the storage tank bracket The top of the gas cylinder bracket 5 is provided with a lower arc groove 7 supporting the gas cylinder; The upper arc-shaped groove 9 corresponding to the shaped groove 7, the air storage cylinder holds the clamping plate 8 and drives it by the holding cylinder 10 vertically located on the air storage cylinder bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com