Metal sheet surface scale grinding and removing machine

A metal sheet and oxide skin technology, which is applied in metal processing equipment, grinding machines, grinding/polishing equipment, etc., can solve the problems of difficulty in ensuring the surface quality of titanium and titanium alloy sheets, large investment in shot blasting equipment removal, and large environmental pollution. , to achieve the effect of high flatness, large range and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Attached below Figure 1-11 An embodiment of the present invention is described.

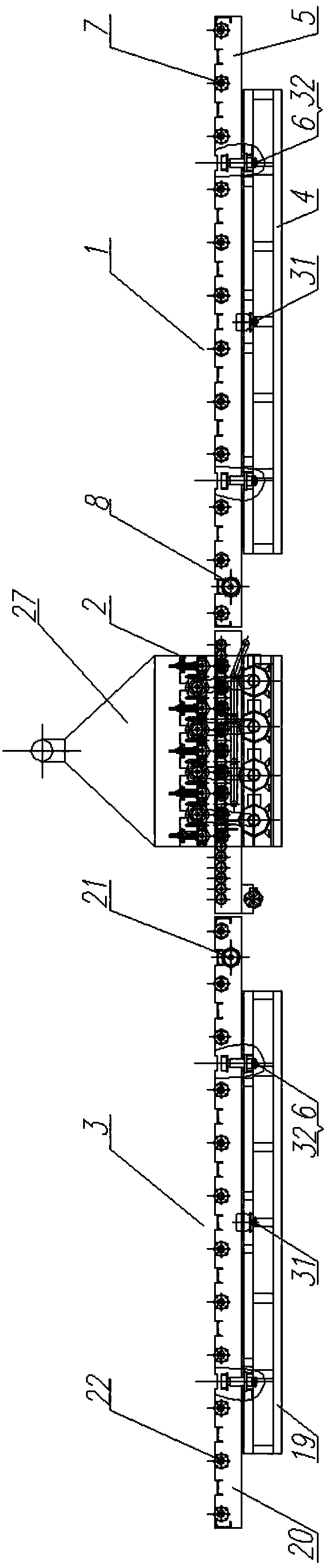

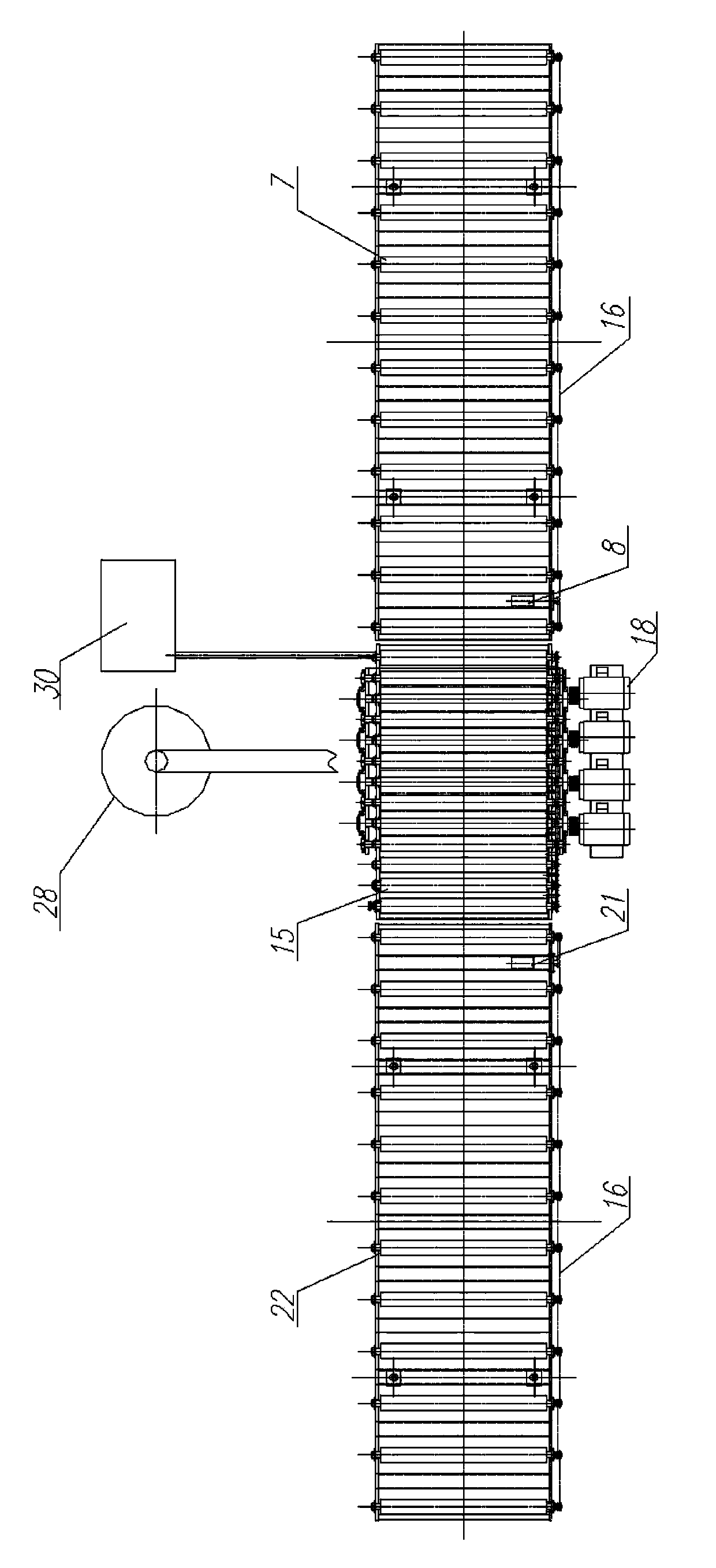

[0033] The machine for grinding and removing oxide skin on the surface of metal plates is composed of a feeding device 1, a grinding device 2 and a discharging device 3 connected in sequence;

[0034] The feed device 1 has a feed base 4 and a feed frame 5; the feed frame 5 is installed above the feed base 4 by a lifting device 6, and the feed frame 5 is fixed with a feed motor 8, installed There are feed rollers 7 arranged in parallel, and the feed motor 8 drives all the feed rollers 7 to rotate in the same direction through the sprocket chain transmission system 16;

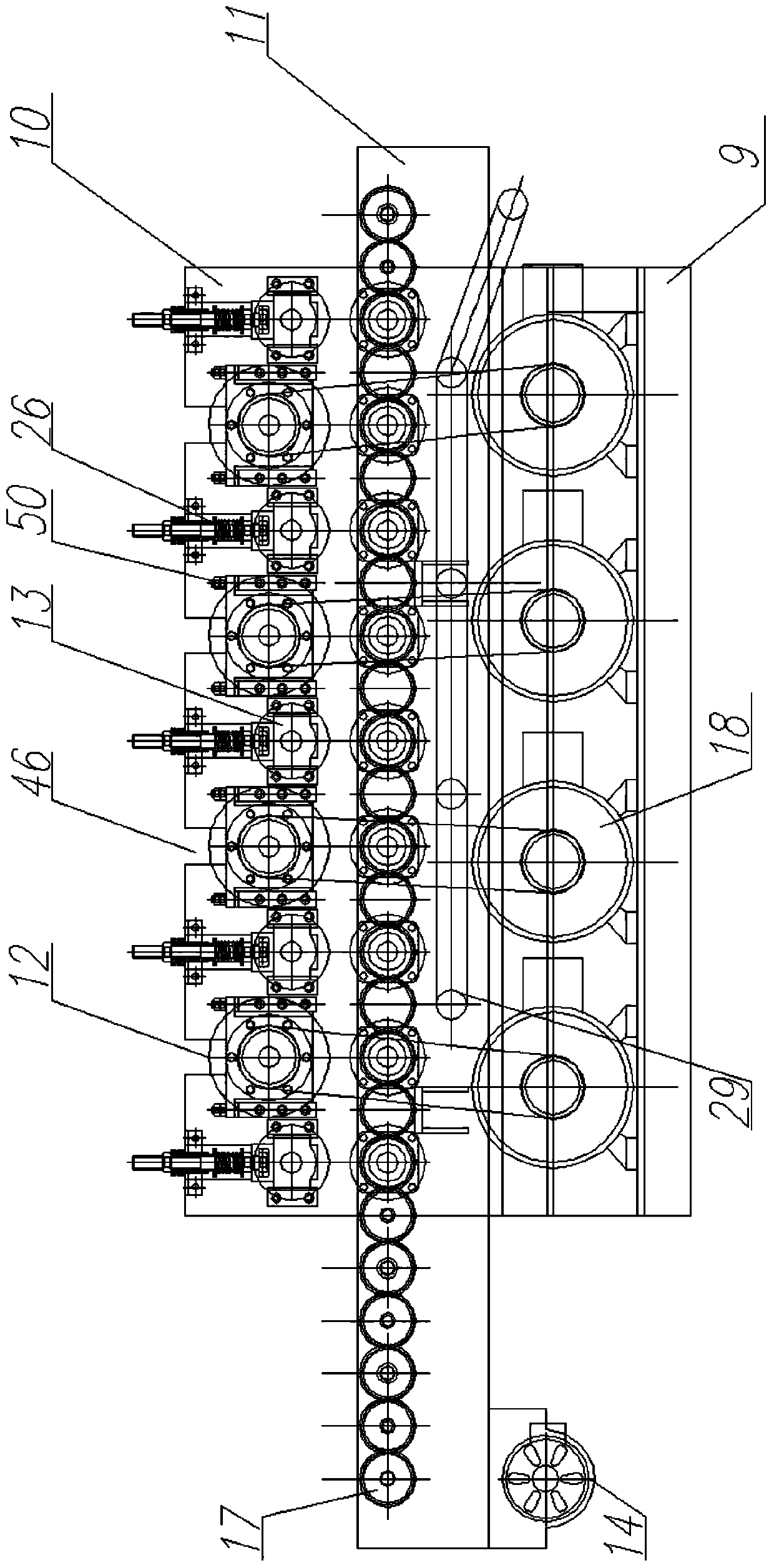

[0035] The grinding device 2 has a grinding base 9, a supporting wallboard 10, and a support frame 11; two supporting wallboards 10 are fixed on the front and rear sides of the grinding base 9, and a grinding roller 12 is fixedly installed between the two supporting wallboards 10. The roller 13 is elastically installed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com