Derusting and polishing device for outer surface of steel pipe

A technology of outer surface and steel pipe, which is applied in the direction of grinding machine, grinding workpiece support, grinding/polishing equipment, etc., which can solve the problems of inconvenient operation, high labor intensity of operators, and large volume of shot blasting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

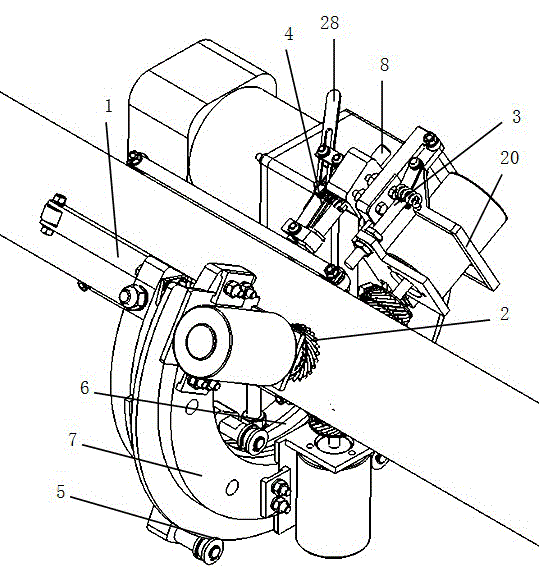

[0020] Combine below figure 1 The present invention will be described.

[0021] Such as figure 1 As shown, the present invention is mainly made up of frame part 1, grinding part 2, sander locking mechanism 3, frame locking mechanism 4, guide rail part 5, reciprocating mechanism 6; On the steel pipe, under the action of the guide rail in the guide rail part 5, the derusting and grinding device performs reciprocating rotation along the circular track; operating the U-shaped connecting rod 20 in the lock mechanism 3 of the grinder can make the motor fast loading and unloading; turn the frame lock Handle 28 in the tightening mechanism 4 can load and unload the derusting and polishing device.

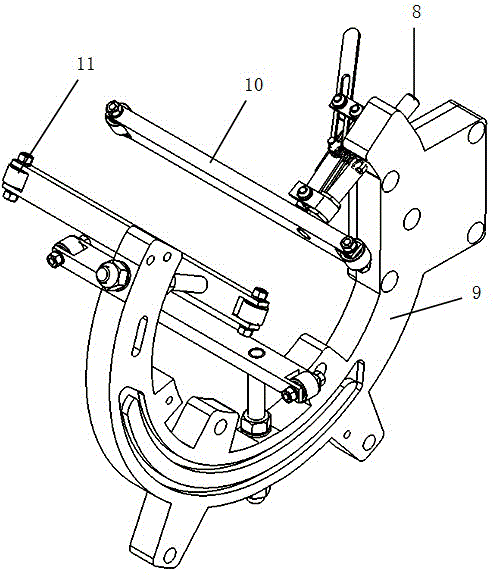

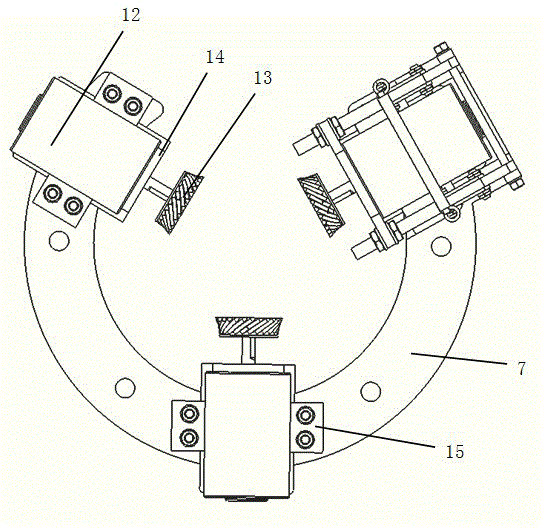

[0022] Combine below figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 The present invention will be described in detail.

[0023] figure 2 It is the frame part 1 of the present invention. Three screw rods 8 are installed on the fixed plate 9, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com